Organic fertilizer for ameliorating salinity and alkalinity of soil and eliminating soil hardening and preparation method of fertilizer

A technology of soil compaction and organic fertilizer, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of unsatisfactory users and ineffective effects, so as to enhance the ability of soil to retain water and fertilizer, eliminate soil compaction, and reduce cell acidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

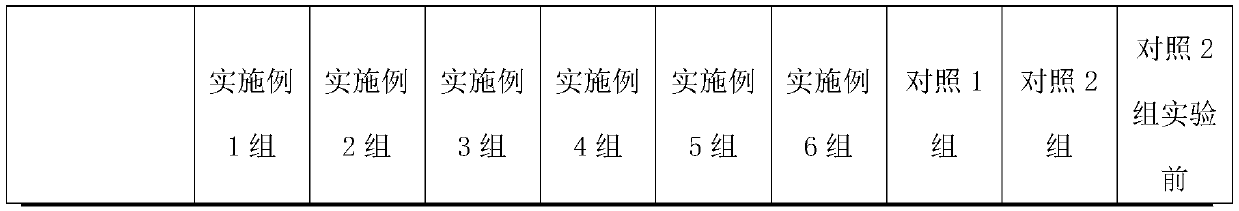

Examples

Embodiment 1

[0029] A kind of preparation method of improving salinity and eliminating the organic fertilizer of soil compaction, it comprises the following steps:

[0030] (1) Preparation of organic acid: mix straw, sawdust, and rice husk in a mass ratio of 1:1:1, put them into a continuous circulating fluidized bed device for sealing and pyrolysis, and the pyrolysis temperature is controlled at 280°C - 310°C, the pyrolysis time is two hours, collect the liquid produced after pyrolysis, stand still, filter, and distill, and keep the distillate in the temperature range of 95°C-150°C to obtain the organic acid;

[0031] (2) Preparation of compound acid: the organic acid prepared in step (1) and the proline fermentation broth with a mass percentage content of 10% are uniformly mixed in proportion, and the organic acid prepared in step (1) accounts for 70% by mass, The mass of proline fermentation broth accounts for 30%;

[0032] (3) Mixing: use a mixing pulverizer to pulverize the fermented...

Embodiment 2

[0034] A kind of preparation method of improving salinity and eliminating the organic fertilizer of soil compaction, it comprises the following steps:

[0035] (1) Preparation of organic acid: mix straw, sawdust, and rice husk in a mass ratio of 2:1:1, put them into a continuous circulating fluidized bed device for sealing and pyrolysis, and the pyrolysis temperature is controlled at 295°C - 350°C, the pyrolysis time is two hours, collect the liquid produced after pyrolysis, stand still, filter, and distill, and keep the distillate in the temperature range of 95°C-120°C to obtain the organic acid;

[0036] (2) Preparation of compound acid: mix the organic acid prepared in step (1) and the proline fermentation broth with a mass percentage content of 15% in proportion, and the organic acid prepared in step (1) accounts for 80% by mass, The mass of proline fermentation broth accounts for 20%;

[0037] (3) Mixing: use a mixing pulverizer to pulverize the fermented livestock and pou...

Embodiment 3

[0039] A kind of preparation method of improving salinity and eliminating the organic fertilizer of soil compaction, it comprises the following steps:

[0040] (1) Preparation of organic acid: mix straw, sawdust, and rice husk in a mass ratio of 1:1:2, put them into a continuous circulating fluidized bed device for sealing and pyrolysis, and the pyrolysis temperature is controlled at 290°C - 330°C, the pyrolysis time is two hours, collect the liquid produced after pyrolysis, stand still, filter, and distill, and keep the distillate in the temperature range of 95°C-130°C to obtain the organic acid;

[0041] (2) Preparation of compound acid: mix the organic acid prepared in step (1) and the proline fermentation broth with a mass percentage content of 10% in proportion, and the organic acid prepared in step (1) accounts for 75% by mass, The mass of proline fermentation broth accounts for 25%;

[0042] (3) Mixing: use a mixing pulverizer to pulverize the fermented livestock and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com