Novel heat preservation and insulation integrated wallboard and manufacturing method thereof

A thermal insulation and new technology, applied in the direction of chemical instruments and methods, manufacturing tools, ceramic molding machines, etc., can solve the problems of complicated process, long cycle, and decreased installation stability, and achieve simple process flow, short construction cycle, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0047] A novel thermal insulation integrated wall panel comprises a concrete wall body, and the concrete wall body is formed by pouring heat-insulation retarded concrete mixture.

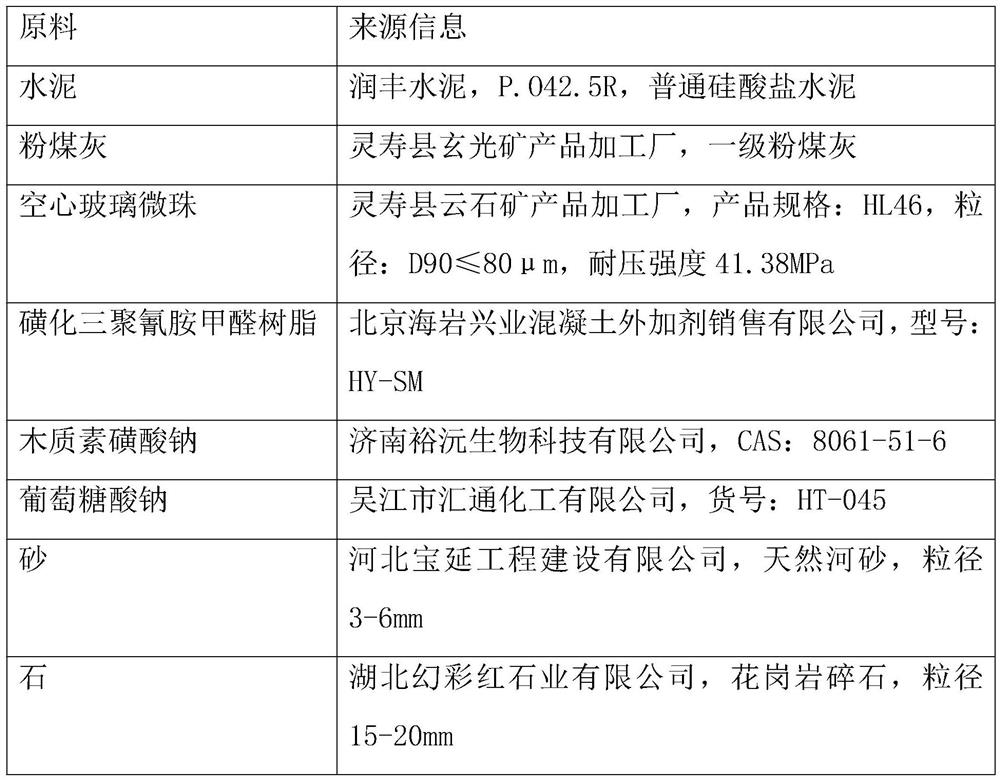

[0048] Insulating concrete mixes consist of the following components:

[0049] Water, cement, fly ash, cenosphere filler, water reducer.

[0050] Among them, the water reducing agent is a compound of sulfonated melamine formaldehyde resin, sodium lignosulfonate and sodium gluconate.

[0051] The mass ratio of sulfonated melamine formaldehyde resin, sodium lignosulfonate and sodium gluconate is 1:0.2:3.

[0052] In Examples 1-3, see Table 2 for the specific input amount (unit: kg) of each component.

[0053] Table 2

[0054] Example 1 Example 2 Example 3 water 14.4 14.5 14.6 cement 33.8 33.86 33.9 fly ash 3.3 3.38 3.4 Cenosphere packing 116.5 116.9 117 Superplasticizer 0.52 0.53 0.54

[0055] In embodiment 1-3, the preparation method of h...

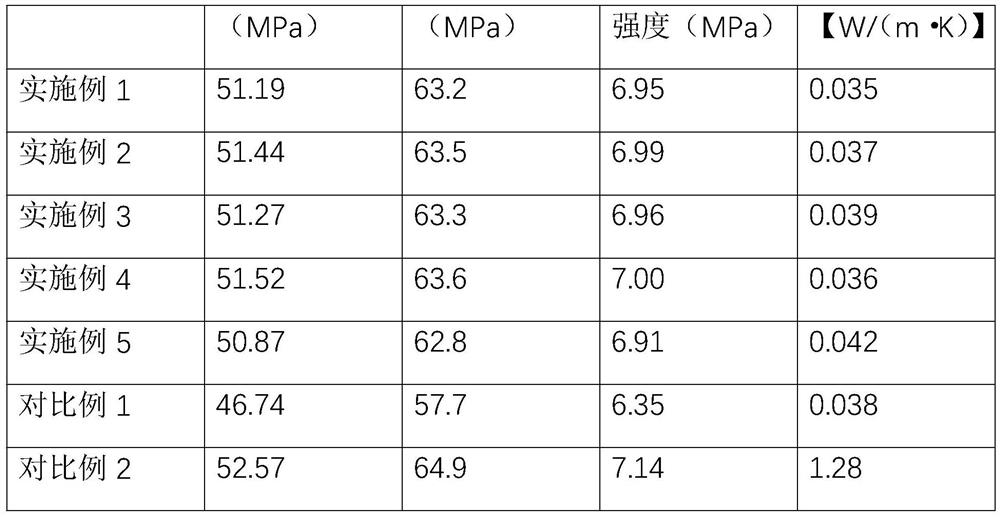

Embodiment 4

[0064] A new type of thermal insulation integrated wallboard, compared with Example 2, the only difference is:

[0065] The preparation method of hollow microsphere filler comprises the following steps:

[0066] Step 1), adding industrial hydrofluoric acid with a concentration of 40% into tap water, stirring evenly to form a hydrofluoric acid solution with a concentration of 12%.

[0067] Step 2), put the hollow glass microspheres into the stirred tank, then inject the hydrofluoric acid solution into the stirred tank, the mass ratio of the hollow glass microspheres to the hydrofluoric acid solution is 1:5, after the hydrofluoric acid solution is injected , at room temperature, with a rotation speed of 120r / min, stirring for 6min, filtering the hollow glass microspheres through a 1000-mesh screen, and then putting the filtered hollow glass microspheres into the cleaning pool. There is a 1000-mesh filter screen, the cleaning tank is injected with clean water at a flow rate of 1...

Embodiment 5

[0070] A new type of thermal insulation integrated wallboard, compared with Example 2, the only difference is:

[0071] The mass ratio of sulfonated melamine formaldehyde resin, sodium lignosulfonate and sodium gluconate is 1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com