Construction device and construction method for stirring and spraying expanded reinforcement pile

A technology of construction device and construction method, which is applied in the direction of drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., and can solve the problems affecting the construction progress and pile body quality, the difficulty of prefabricated pile hammering construction, pile head or pile bottom Problems such as cracking and cracking can be solved, and the effect of increasing the area around the pile, improving the side friction resistance and overall strength, and increasing the area around the pile and at the bottom of the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

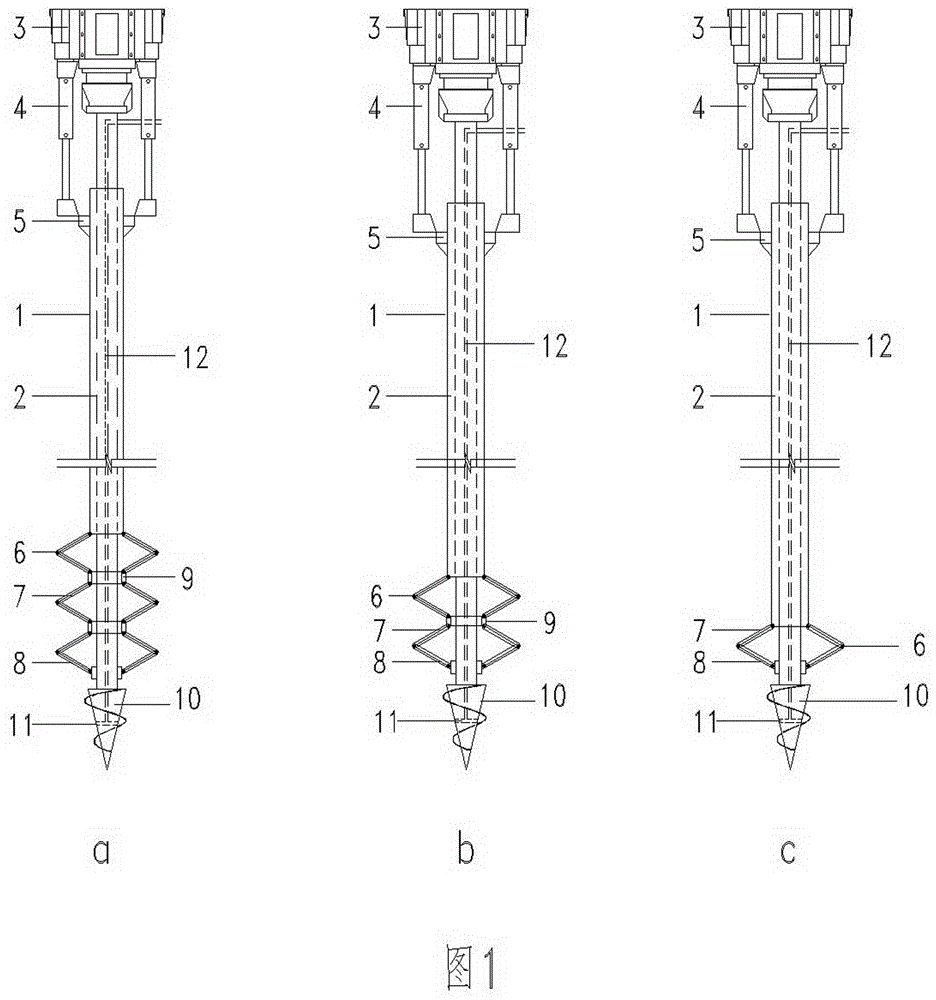

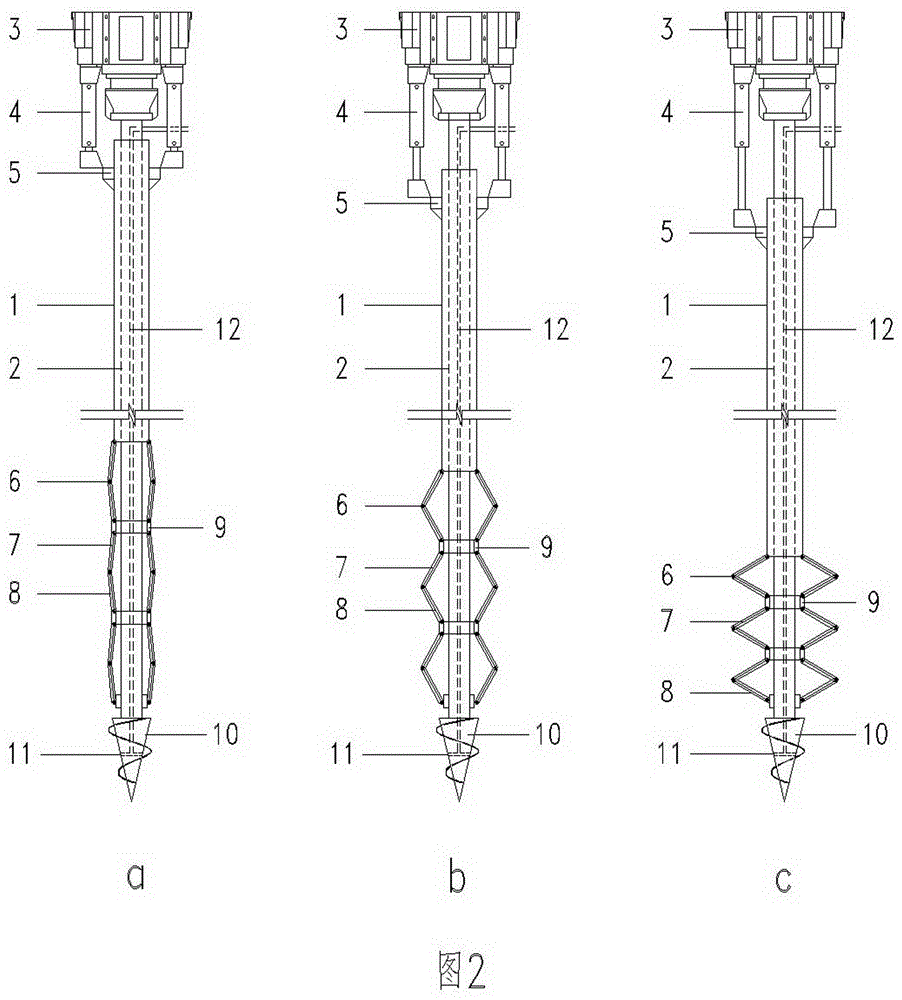

[0049] figure 1 It is a schematic structural view of the construction device of the present invention, as figure 1 As shown in a, the drill pipe is coaxially stacked by a hollow outer tube 1 and a hollow inner tube 2. A rotating power mechanism 3 and a lifting device 4 are arranged above the drill pipe. The rotating power mechanism 3 controls the rotation of the inner pipe 2, and the inner pipe 2 The outer wall of the outer tube and the inner wall of the outer tube 1 are engaged through a certain height of vertical slots or polygonal bearings, so that the inner tube 2 can drive the outer tube 1 to rotate synchronously. The lifting device 4 is two hydraulic cylinders distributed left and right. The upper end of the hydraulic cylinder It is fixed with the rotating power system 3, and the lower end and the top end of the outer pipe 1 are fixed through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com