Extra-huge-volume concrete one-time continuous pouring multi-cycle real-time temperature control construction technology

A construction technology and multi-cycle technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of little effect, labor-intensive, time-consuming, etc., achieve obvious effect, reduce construction cost, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

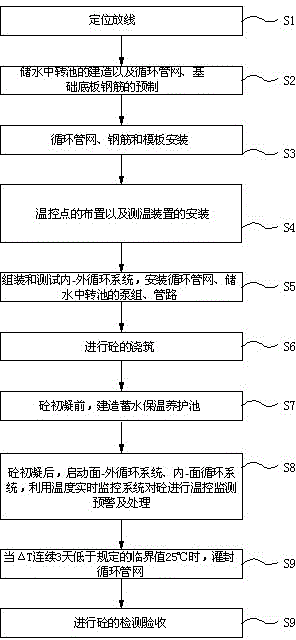

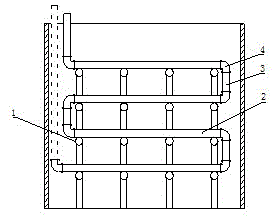

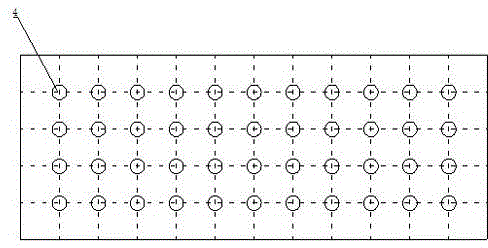

[0061] see figure 1 , the present invention discloses a multi-cycle real-time temperature-controlled construction technology for continuous pouring of super-large-volume concrete at one time. The water storage transfer pool built by masonry at the construction site; the inner-surface circulation system is formed by pipelines between the circulating pipe network and the water storage and maintenance pool; the surface-outer circulation system is formed by pipelines between the water storage and maintenance pool and the water storage transfer pool ; The internal-external circulation system is formed by pipelines between the circulation pipe network and the water storage transfer pool; the three circulation systems are controlled by the temperature real-time monitoring system to work together to control the real-time temperature of super-large-volume concrete construction.

[0062] Specific steps include:

[0063] Before construction, it is first necessary to calculate the maxim...

Embodiment 1

[0273] Wuhu Bozhuang Spring Blossom Phase V new construction project

[0274] The project is located at Weiqi Road, Wushi Road, Wuhu City, Anhui Province. The frame-shear structure consists of 1 floor underground and 28 floors above the ground, with a total construction area of 98,630m2 2 . The foundation floor is composed of main building rafts (H=3800mm) and podium rafts (H=1700mm), and the underground building area is 30099m 2 , is a super-large volume concrete floor. The base plate pouring construction is in the high temperature period in summer from July to August (the average daytime temperature is above 35 degrees).

[0275] The project adopts this technology, and the interior of the raft foundation is preset in groups according to the circulating pipe network, the surface of the raft foundation is stored and maintained, and the precipitation recharge and rainwater collection system on the construction site are adopted. The combined dual-control monitoring method...

Embodiment 2

[0277] Wuhu Shimao Riverside Garden 4-1# plot characteristic commercial street project

[0278] The project is located on Beijing West Road, Wuhu City, Anhui Province, with a total construction area of 78463m 2 , one basement floor, with an underground building area of about 21,230m 2 , the thickness of the basement floor is 800mm, the thickness of the cap is mainly 2200mm and 2600mm, and the maximum thickness of the core tube foundation concrete is 5300mm. The concrete pouring of the basement floor was at the end of July, which is midsummer and the average daily temperature is above 30°C. This project applies this technology, and the circulating pipe network is preset in groups in the raft foundation. The internal circulation water and the surface water storage and maintenance water of the raft foundation come from the groundwater of precipitation, as well as the precipitation recharge and rainwater collection system on the construction site. The dual-control monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com