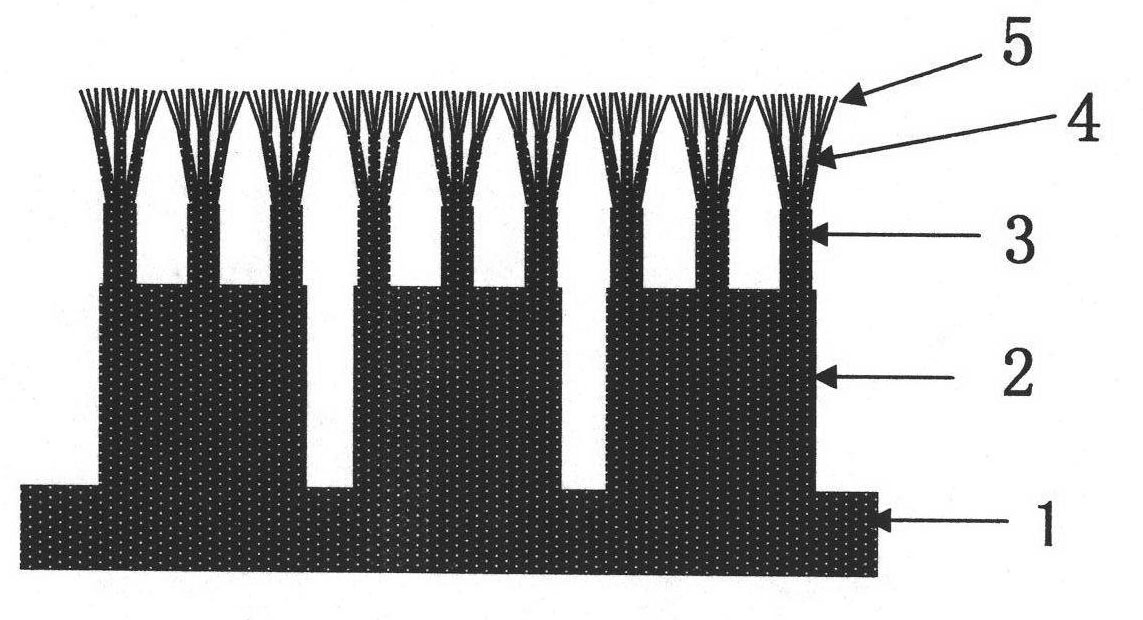

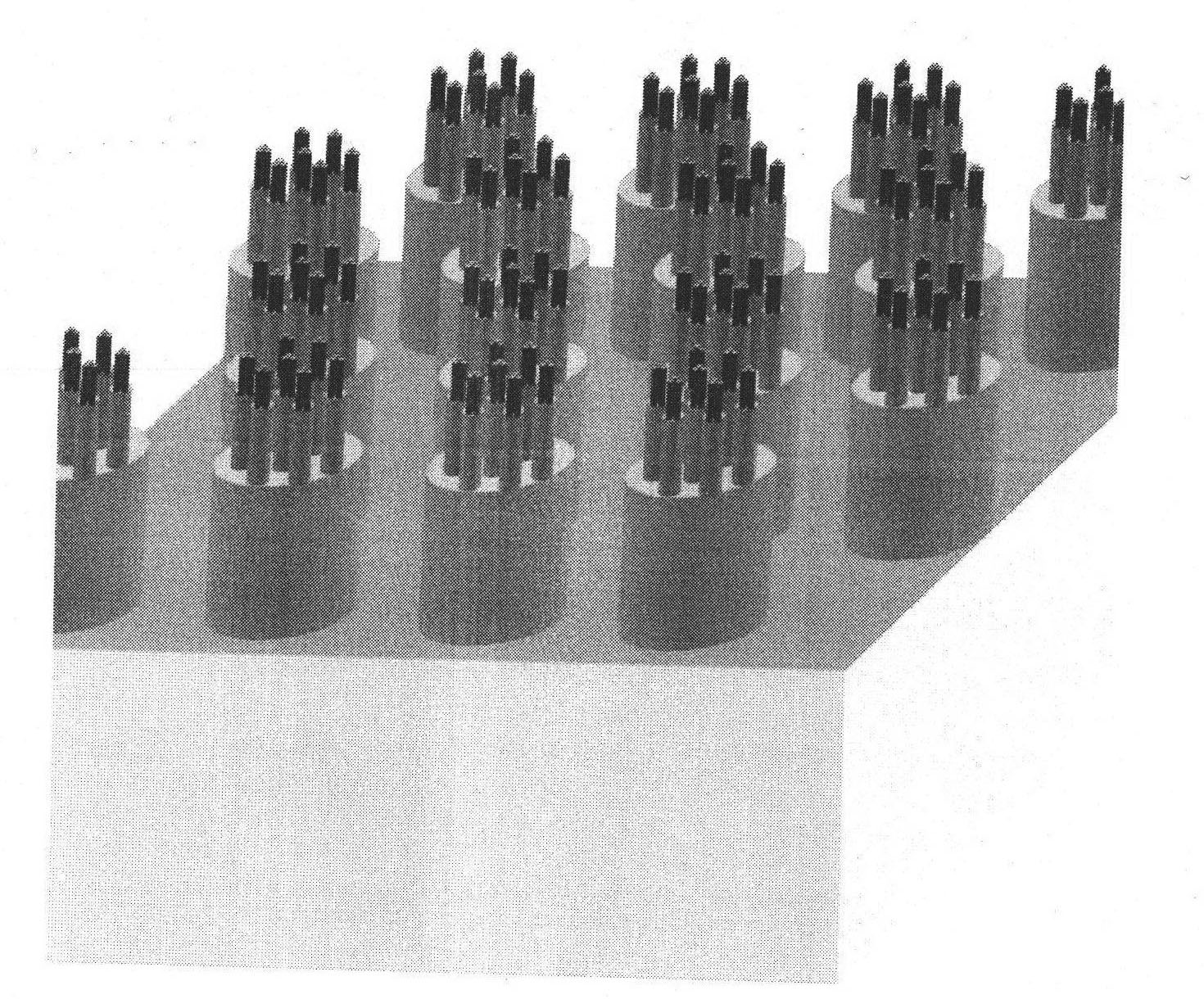

Cross-scale biomimetic micro-nano branch structure array and preparation method thereof

A branched structure, micro-nano technology, applied in the fields of micro-nano materials and robotics, can solve the problems of not achieving the adjustable parameters of the micro-nano structure, difficulty in ordering structure, and inability to meet the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The high-purity aluminum sheet is ultrasonically cleaned in acetone and ethanol in sequence to remove oil stains on the surface of the aluminum sheet.

[0025] (2) After drying the decontaminated high-purity aluminum flakes, 2 Or placed in a tube furnace in an inert atmosphere, and annealed at 500 ° C for 4 hours.

[0026] (3) The aluminum sheet after annealing is carried out electrochemical polishing in the mixed solution (ethanol:perchloric acid=9:1 volume ratio) of absolute ethanol and perchloric acid, with graphite as negative electrode, voltage is 20V, eliminates aluminum Scratches and oxide layers on the chip surface.

[0027] (4) Obtain a photoresist mask pattern on the surface of the aluminum sheet by ultraviolet lithography.

[0028] (5) Carry out argon ion beam etching on the aluminum sheet with a photoresist mask, the ion energy is 500eV, the ion beam is vertically incident, and the beam current density is 0.5mA / cm 2 , working pressure 2×10 -2 Pa, an ...

Embodiment 2

[0036] (1) The high-purity aluminum sheet is ultrasonically cleaned in acetone and ethanol in sequence to remove oil stains on the surface of the aluminum sheet.

[0037] (2) After drying the high-purity aluminum flakes after degreasing, in N 2 Or placed in a tube furnace in an inert atmosphere, and annealed at 500 ° C for 4 hours.

[0038] (3) The aluminum sheet after annealing is carried out electrochemical polishing in the mixed solution (ethanol:perchloric acid=9:1 volume ratio) of absolute ethanol and perchloric acid, with graphite as negative electrode, voltage is 20V, eliminates aluminum Scratches and oxide layers on the chip surface.

[0039] (4) Obtain a photoresist mask pattern on the surface of the aluminum sheet by ultraviolet lithography.

[0040] (5) Argon ion beam etching is carried out on the aluminum sheet with a photoresist mask, the ion energy is 600V, the ion beam incident angle is 30°, and the beam current density is 0.6mA / cm 2 , working pressure 2×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com