A kind of battery colloidal electrolyte and preparation method thereof

A colloidal electrolyte and storage battery technology, which is applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of short gel time, high cost, and difficult glue pouring, and achieve stable electrochemical performance and dispersion Increased time and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: Containing the colloidal electrolyte of additive

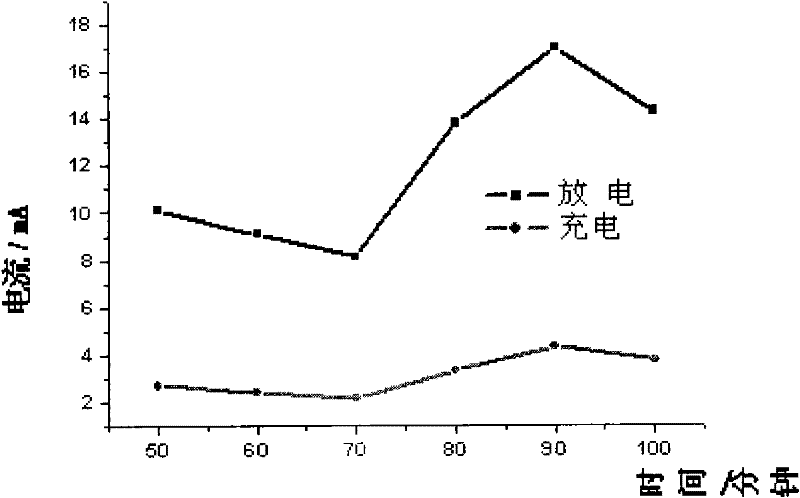

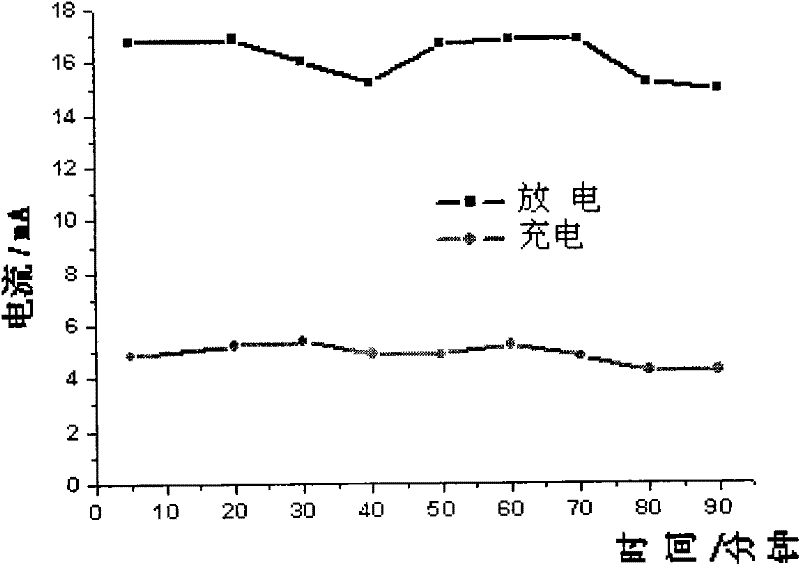

[0020] The reagents and materials used in the colloidal electrolyte for valve-regulated sealed lead-acid batteries include: analytically pure concentrated sulfuric acid, produced by Guangzhou Reagent Factory, A200 fumed silica, imported from Germany, and the particle size of A200 fumed silica is 10nm Left and right, and the particle size distribution is uniform. Except for ionized water in the electrolytic solution, the percentages of other effective components in the total amount are: 36% of sulfuric acid and 5% of fumed silicon dioxide. When fumed silica is dispersed in dilute sulfuric acid solution, the dispersion temperature should be controlled at about 30°C, and the mechanical dispersion rate should be at 4000r / min. The mechanical dispersion time ranges from 5 to 100 minutes.

[0021] A. At 30°C, measure 266mL of analytically pure concentrated sulfuric acid (d=1.84g / mL), mix it with 796mL of deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com