A kind of preparation method of acrylonitrile-based carbon fiber spinning liquid and its polymerization reaction equipment

An acrylonitrile-based carbon fiber, polymerization reaction technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of uneven material properties and structure, and achieve the effect of good mixing effect, improved reaction degree and reliable mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

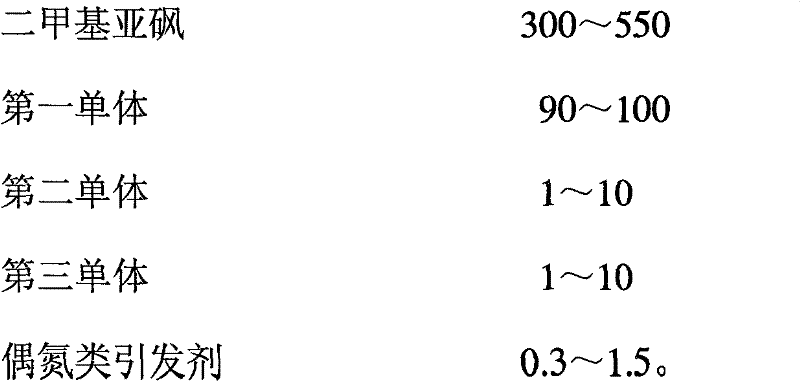

[0026] Example 1: Weigh 20Kg dimethyl sulfoxide, 6.336Kg acrylonitrile, 132g acrylamide and 66g itaconic acid, and pour them into a 50L reaction kettle in turn, after stirring and dissolving completely, bubbling with argon for 20min to remove the solution and There is air in the kettle, and at the same time, 50°C hot water is passed through the jacket of the reaction kettle. When the temperature of the material is 50°C, add 36.3g of azobisisoheptanonitrile, the reaction starts, and after 30min, the twin-screw reaction extruder is opened to circulate the material, and the output of the extruder is 50Kg / h, and the temperature of the jacket of the extruder is kept at 50 ℃. At the same time, 3.4 kg of dimethyl sulfoxide and 66 g of itaconic acid were added to the feeding tank of the extruder, and the feeding was completed within 3 hours with a metering pump. Discharging after 15 hours of polymerization. The conversion rate is 92.6%, the weight average molecular weight is 158,000...

Embodiment 2

[0027] Example 2: Weigh 20Kg dimethyl sulfoxide, 6.336kg acrylonitrile, 132g acrylamide and 66g itaconic acid, and pour them into a 50L reaction kettle in turn, after stirring and dissolving completely, bubbling with argon for 20min to remove the solution and Air in the kettle, while hot water at 45°C was passed through the jacket of the reaction kettle. When the temperature of the material is 50°C, add 46.2g of azobisisoheptanonitrile, the reaction begins, and after 30min, two sets of twin-screw reaction extruders in series are opened to circulate the material, and the output of the extruder is 50Kg / h, and the extruder is kept The jacket temperature was 45°C. At the same time, 3.4 kg of dimethyl sulfoxide and 66 g of itaconic acid were added to the feeding tank of the extruder, and the feeding was completed within 3 hours with a metering pump. Discharging after 20 hours of polymerization. The conversion rate is 95.1%, the weight average molecular weight is 135,000, and the ...

Embodiment 3

[0028] Example 3: Weigh 17.5Kg dimethyl sulfoxide, 4.85kg acrylonitrile, 75g methyl acrylate and 30g itaconic acid, pour them into a 50L reaction kettle in turn, stir and dissolve completely, and then bubble with argon for 20min to remove solution and the air in the kettle, and at the same time, hot water at 60°C was passed through the jacket of the reaction kettle. When the temperature of the material is 60°C, add 30.0g of azobisisobutyronitrile, the reaction starts, and after 30 minutes, open two series-connected twin-screw reaction extruders to circulate the material, and the output of the extruders is 50Kg / h. The jacket temperature was 60°C. At the same time, 2.5kg of dimethyl sulfoxide and 35g of itaconic acid were added to the feeding tank of the extruder, and the feeding was completed within 4 hours with a metering pump. Discharging after 12 hours of polymerization. The conversion rate is 91.6%, the weight average molecular weight is 132,000, and the molecular weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com