Hydrophilic fluorinated polymer and preparation method thereof

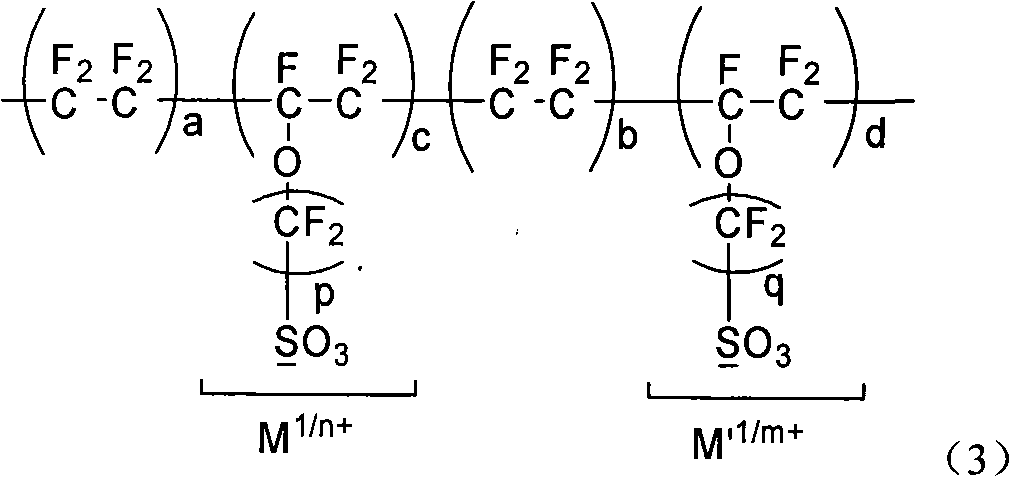

A high-polymer and hydrophilic technology, applied in the field of multi-component copolymerized perfluororesin and its preparation, can solve the problem of insufficient resin molecular weight, and achieve the effects of excellent anti-oxidation performance, high current efficiency and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, p=2, q=3

[0048] Reactor is cleaned and adds 4.0L deionized water, 1000ml contains 570g cerium sulfonate pendant vinyl ether monomer (1) ((F 2 C=CF-O-CF 2 CF 2 -SO 3 - ) 4 Ce 4+ ) and 450g cerium sulfonate pendant vinyl ether monomer (2) (F 2 C=CF-O-CF 2 --CF 2 CF 2 -SO 3 - ) 3 Ce 3+ ) aqueous solution, start the stirring device, vacuumize and replace with high-purity nitrogen three times, after the oxygen content in the test reactor is below 1ppm, vacuumize, fill the reactor with tetrafluoroethylene monomer until the pressure is 2.4MPa, and heat up to At 25°C, add 2.8g of perfluorobutyryl peroxide (CF 3 CF 2 CF 2 CO-OO-CCF 2 CF 2 CF 3 ) initiates the polymerization reaction, and continuously feeds tetrafluoroethylene (CF 2 = CF 2 ) monomer to keep the reaction pressure at 2.4 MPa, add 0.72 g of initiator to the system every 15 minutes, stop adding the initiator after reacting for 2 hours, let the reaction continue for 15 minutes, the...

Embodiment 2

[0051] Embodiment 2, p=2, q=3

[0052] Reactor is cleaned and adds 4.0L deionized water, 1000ml contains 605g cerium sulfonate pendant vinyl ether monomer (1) ((F 2 C=CF-O-CF 2 CF 2 -SO 3 - ) 3 Ce 3+ ) and 150g manganese sulfonate pendant vinyl ether monomer (2) ((F 2 C=CF-O-CF 2 -CF 2 CF 2 -SO 3 - ) 2 mn 2+) aqueous solution, start the stirring device, vacuumize and replace with high-purity nitrogen for three times, after the oxygen content in the test reactor is below 1ppm, vacuumize, fill the reactor with tetrafluoroethylene monomer until the pressure is 2.7MPa, and heat up to At 35°C, add 8.2g perfluoropropoxypropyl peroxide (CF 3 CF 2 CF 2 OCF (CF 3 )CO-OO-CCF(CF 3 )OCF 2 CF 2 CF 3 ) to initiate the polymerization reaction, continue to feed tetrafluoroethylene monomer to keep the reaction pressure at 2.7MPa, add 2.48g of initiator to the system every 25min, after reacting for 2.5h, stop adding the initiator, let the reaction continue for 25min, stop a...

Embodiment 3

[0055] Embodiment 3, p=2, q=3

[0056] Reactor is cleaned and adds 4.0L deionized water, 1000ml contains 500g molybdenum sulfonate pendant vinyl ether monomer (1) ((F 2 C=CF-O-CF 2 CF 2 -SO 3 - ) 3 Mo 3+ ) and 380g tungsten sulfonate pendant vinyl ether monomer (2) ((F 2 C=CF-O-CF 2 -CF 2 CF 2 -SO 3 ) 3 W 3+ ) aqueous solution, start the stirring device, vacuumize and replace with high-purity nitrogen for three times, after the oxygen content in the reactor is tested to be below 1ppm, vacuumize, fill the reactor with tetrafluoroethylene monomer until the pressure is 3.0MPa, and heat up to At 60°C, use a metering pump to add 300 g of 10 wt % ammonium persulfate aqueous solution to initiate the polymerization reaction, continuously feed tetrafluoroethylene monomer to keep the reaction pressure at 3.0 MPa, and stop adding tetrafluoroethylene monomer after reacting for 3 hours. Cool the reaction kettle through the cooling circulation system, and recover the unreacted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com