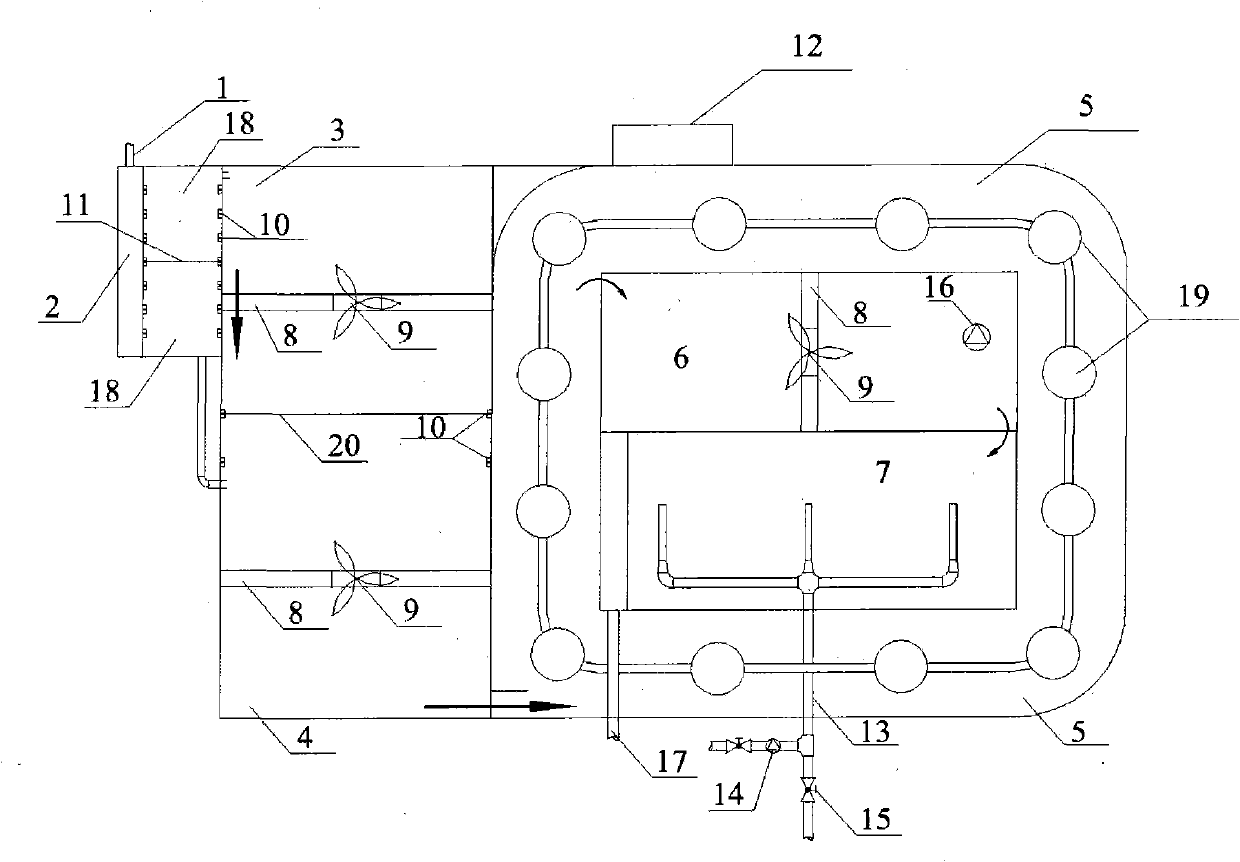

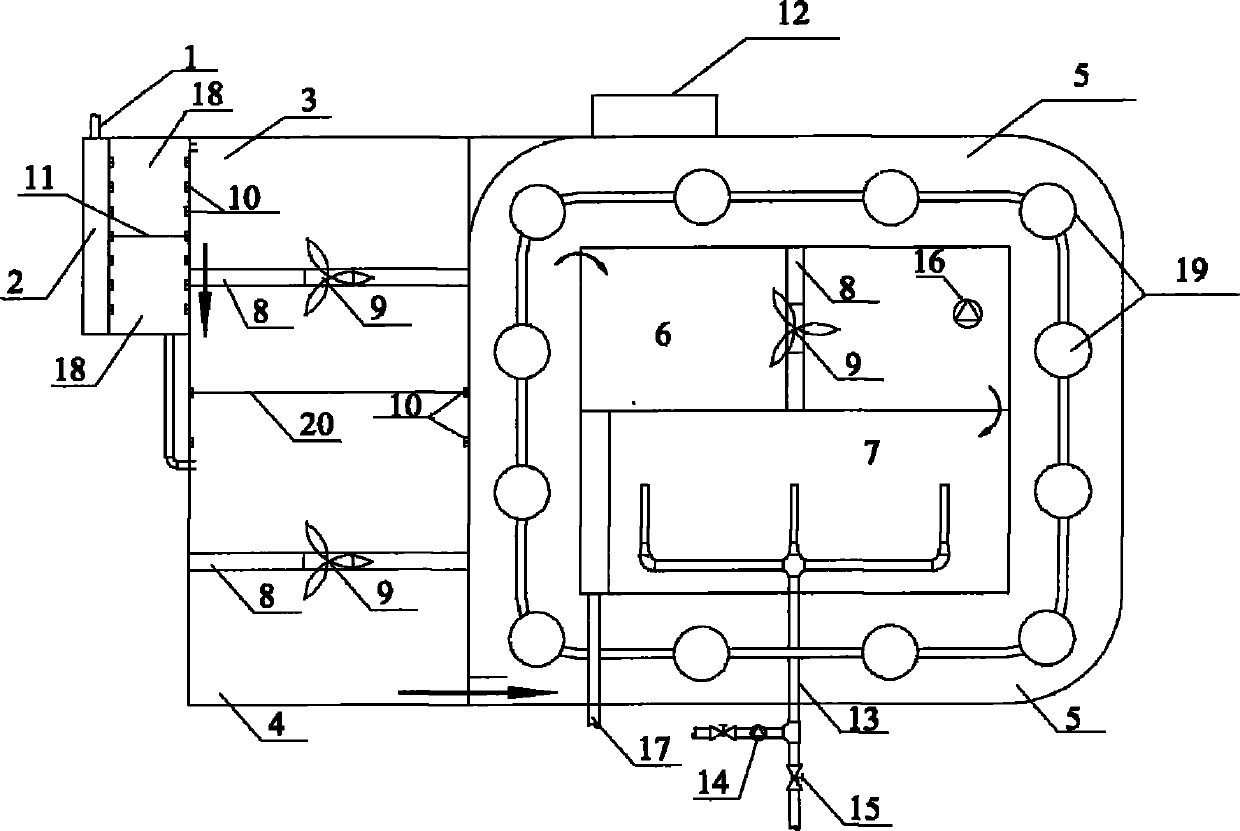

Anaerobic-anoxic-hypoxic integrated reactor and application thereof

A reactor and sewage reactor technology, applied in anaerobic digestion treatment, chemical instruments and methods, aerobic and anaerobic process treatment, etc., can solve the problem of insufficient carbon source, poor simultaneous removal of nitrogen and phosphorus, and high energy consumption problems, to achieve the effect of saving pharmaceutical costs, saving floor space, and alleviating the contradiction of matrix competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

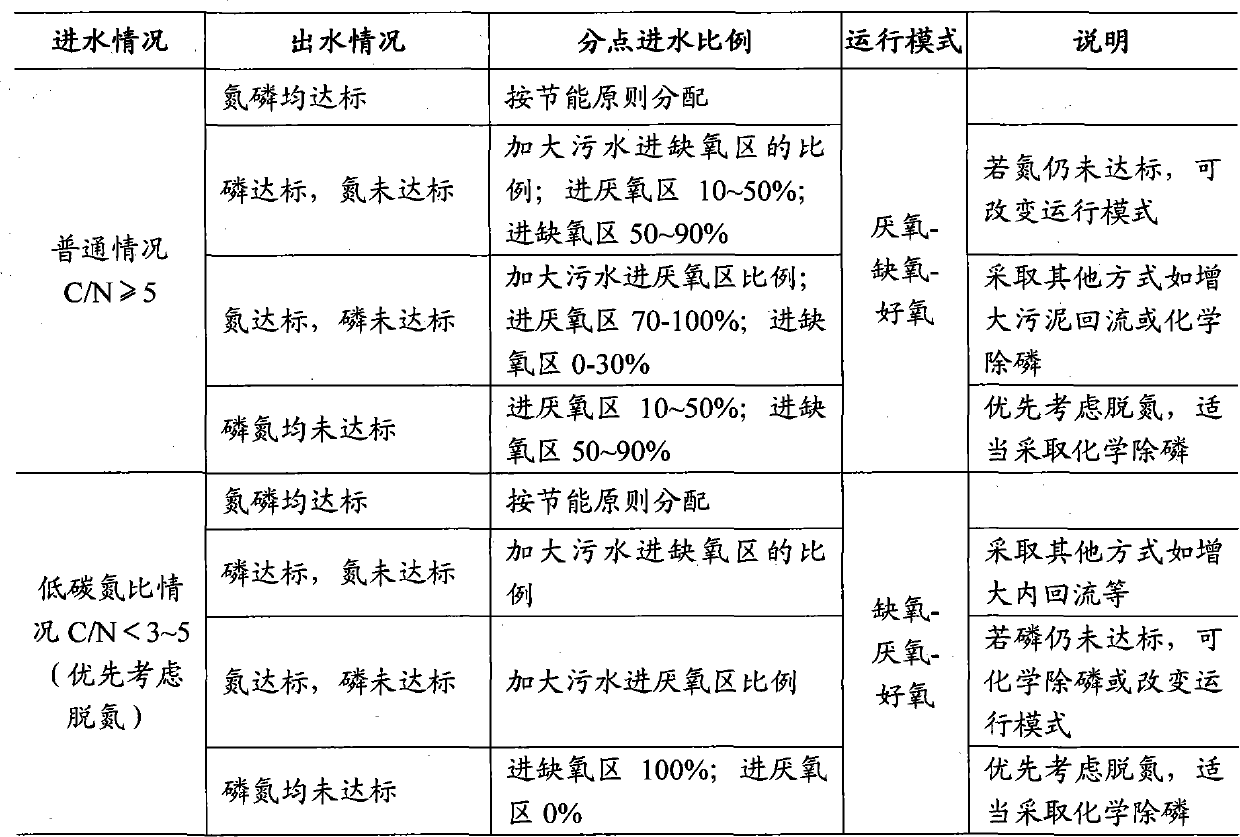

Method used

Image

Examples

specific Embodiment approach 2

[0045] Specific embodiment 2: Taking the effluent from the primary sedimentation tank of Wuxi Lucun Wastewater Treatment Plant Phase I as the treatment object (the water quality index is shown in Table 2), using the treatment method of specific embodiment 1, the effluent TN is 7.14-16.33mg L -1 , average 10.59mg·L -1 , the removal rate was 53.67%-92.19%, and the average removal rate was 75.63%. Effluent NH 3 -N is 0.08~7.70mg·L -1 , average 2.17mg·L -1 , the removal rate was 75.98% to 99.64%, and the average removal rate was 94.91%. Effluent TP is 0.22~0.60mg·L -1 , average 0.39mg·L -1 , the removal rate was 83.69% to 98.46%, and the average removal rate was 92.90%. Effluent COD is 12.00~53.10mg·L -1 , average 34.30mg·L -1 , the removal rate is 80.73% to 94.11%, the average removal rate is 88.38%, and the first-class A compliance rate is 98.45%.

[0046] Table 2 Statistical table of effluent water quality of Wuxi Lucun Wastewater Treatment Plant Phase I Primary Settli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com