Method for preparing thermoplastic resin film

A thermoplastic resin and film technology, used in flat products, applications, household appliances, etc., can solve the problems of difficult to control the vertical and horizontal orientation, difficult to control the resin temperature, complicated factors affecting the equipment process, etc., to achieve the internal molecular arrangement and distribution. Uniform and reasonable, optical performance and gas permeability improvement, the effect of expanding the temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

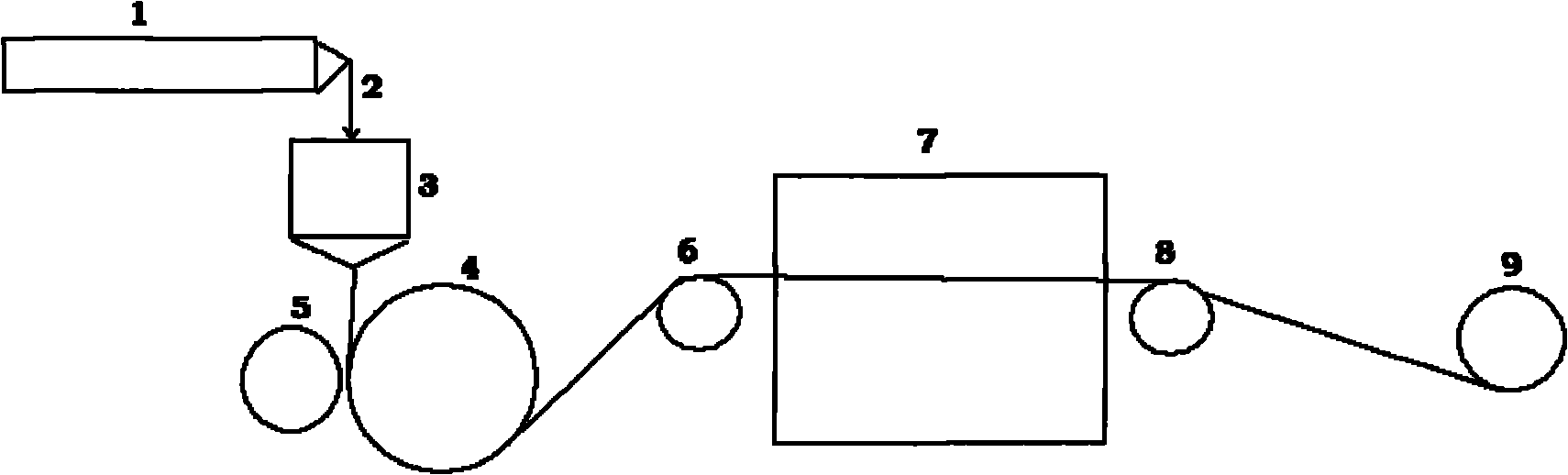

[0025] according to figure 1 Process flow sheet shown, the corresponding blended thermoplastic resin (LDPE, PP, PA6, PET) in Table 1 and other auxiliary agent antioxidant 1010 are uniformly mixed by 100% and 1% by weight, flow from the die mouth Extruded, cooled by a quenching roll at a temperature of 10-60°C to make a film with a thickness of 10-100 μm, and then according to the heat treatment process conditions of Examples 1-4 corresponding to Table 2, heat treatment with a touch roll to obtain a thickness A film of 10-100 μm is used to obtain the thermoplastic resin film material of the present invention.

Embodiment 5~9

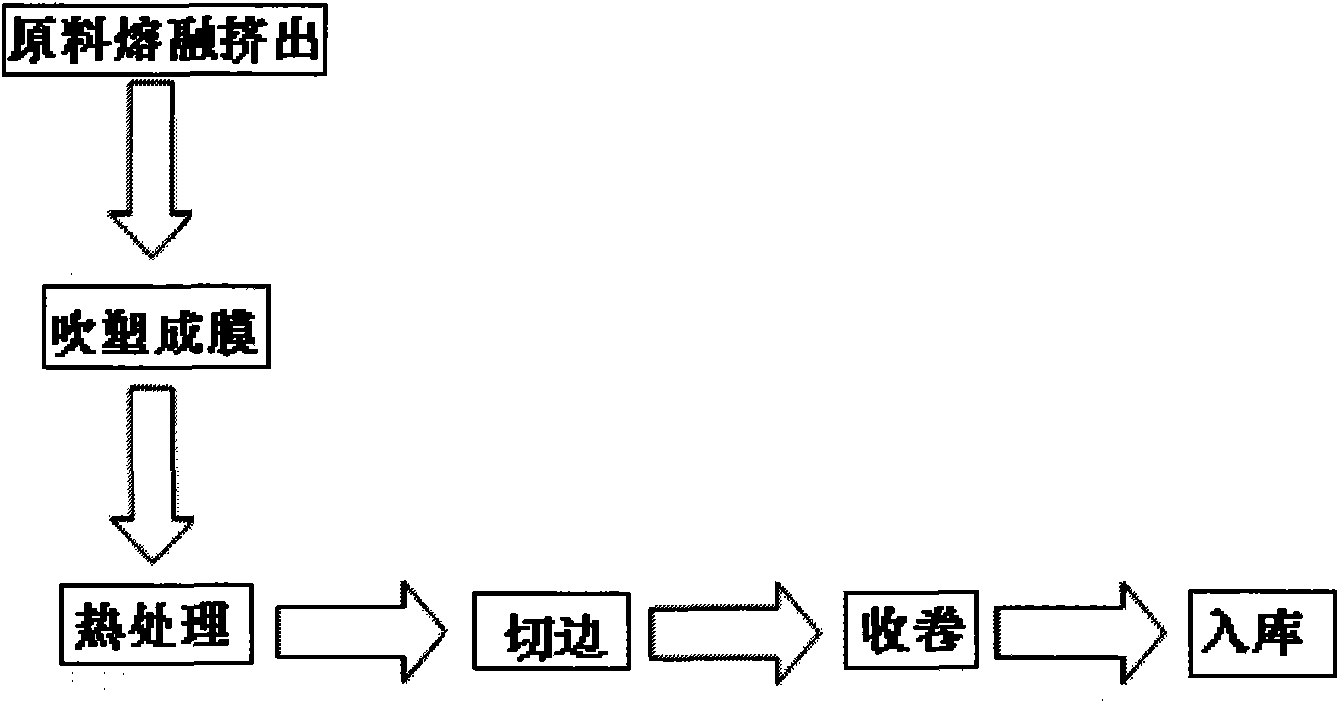

[0027] According to attached figure 2As shown in the process flow diagram, the corresponding blended thermoplastic resins (PS, TPU, TPE, TPEA, TPO) in Table 1 and other additives and antioxidants 1010 are uniformly mixed at a weight percentage of 1%, and blown into a film The film tube is melted and extruded by the extruder, and the film tube is formed through the die; the film tube is blown into the compressed air through the wind ring to inflate the film tube, and then cooled and shaped by the shaping frame, and then the film is flattened with a herringbone plate tube, made into a film, and then according to the heat treatment process conditions of Examples 5 to 9 corresponding to Table 2, heat treatment with a touch roll to prepare a film with a thickness of 10 to 100 μm, that is, the thermoplastic resin film material of the present invention.

[0028] Table 1 (ratio is weight percent)

[0029]

[0030] Table 2

[0031]

Embodiment 10

[0033] Attached figure 1 In the process flow shown, the thermoplastic resin PET, modified resin PA66 and its compatibilizer are uniformly mixed in a weight ratio of 60:34:6, and then cast and extruded from the die head, passing through a temperature of 15-50 ° C. The quenching roll is cooled to form a thin film, and the 2 Under the conveying, enter the heat treatment process stage of the touch roller, the temperature is 240 ~ 190 ℃, after 0.5 ~ 1.5s, natural cooling and winding, the film with a thickness of 10 ~ 100 μm is obtained, that is, the thermoplastic resin film material of the present invention is obtained. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com