Artificial bone with porous laminated structure and passages and preparation method thereof

A laminated structure, artificial bone technology, applied in bone implants, medical science, prosthesis, etc., can solve unfavorable bone cell adhesion, proliferation, differentiation, growth of new bone tissue, lack of bone cell pores and body fluid channels , can not be used for bone defect repair and other problems, to achieve good biocompatibility, conducive to ingrowth and vascularization, and to speed up the effect of repair and reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

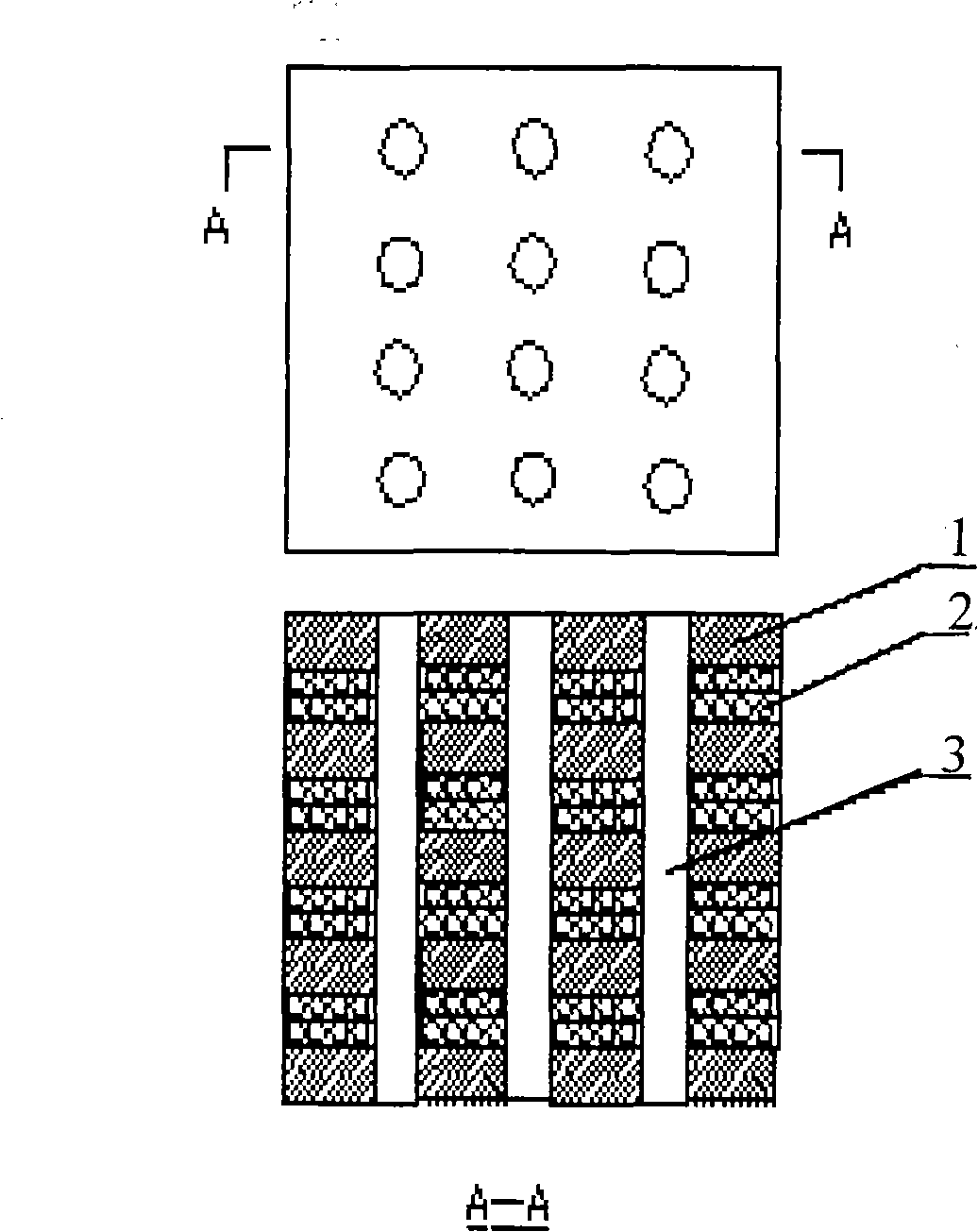

[0035] The artificial bone in this embodiment is formed by alternating dense layers and porous layers of calcium phosphate-based bioceramic materials, and channels for transporting cells and body fluids are provided in a direction at a certain angle to the layers. Among them, the thickness of the dense layer of the artificial bone is 0.1mm, the thickness of the porous layer is 0.3mm, the diameter of the pores is 0.1-0.3mm, the porosity is 20%-60%, the diameter of the channel is 0.5-0.6mm, and the gap between the channel and the laminate is The angle is 10°, and the channel spacing is 1-2mm.

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] (1) taking 100wt% hydroxyapatite (HA) as raw material powder;

[0038] (2) The powder in (1) is mixed with deionized water according to the volume percentage of solid phase content of 30vol%, and the content of the gelling agent sodium alginate relative to the weight percentage of deionized wa...

Embodiment 2

[0046] The artificial bone in this embodiment is formed by alternating dense layers and porous layers of calcium phosphate-based bioceramic materials, and channels for transporting cells and body fluids are provided in a direction at a certain angle to the layers. Among them, the thickness of the dense layer of the artificial bone is 0.5mm, the thickness of the porous layer is 0.6mm, the diameter of the pores is 0.2-0.4mm, the porosity is 30%-70%, the diameter of the channel is 1mm, and the angle between the channel and the stack is The spacing between the 30° channels is 2-3mm.

[0047] The preparation method of the present embodiment comprises the following steps:

[0048] (1) beta-tricalcium phosphate with a content of 100wt% as raw material powder;

[0049] (2) The powder in (1) is mixed with deionized water according to the volume percentage of solid phase content of 40vol%, and the content of the gelling agent sodium alginate relative to the weight percentage of deioniz...

Embodiment 3

[0057] The artificial bone in this embodiment is formed by alternating dense layers and porous layers of calcium phosphate-based bioceramic materials, and channels for transporting cells and body fluids are provided in a direction at a certain angle to the layers. Among them, the thickness of the dense layer of the artificial bone is 1.6mm, the thickness of the porous layer is 1.6mm, the pore diameter is 0.3-0.5mm, the porosity is 30%-60%, the channel diameter is 1.2mm, the angle between the channel and the lamination The spacing between channels for 60° is 1-3mm.

[0058] The preparation method of the present embodiment comprises the following steps:

[0059] (1) mixing 60wt% hydroxyapatite (HA) and 40wt% beta-tricalcium phosphate (beta-TCP) powder;

[0060] (2) The mixed powder in (1) is mixed with deionized water according to the volume percentage of solid phase content of 50vol%, and the content of the gelling agent sodium alginate relative to the weight percentage of dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com