Environment-friendly cut tobacco expanding agent composition

A technology of an expansion agent and a composition, applied in the field of chemical treatment of tobacco, can solve the problems of increasing carbon dioxide emissions, unfavorable environmental protection, difficult manufacturing costs, etc., and achieves the effects of high decomposition temperature, environmental protection, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

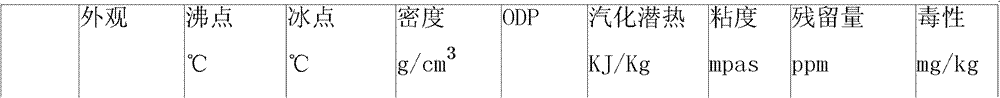

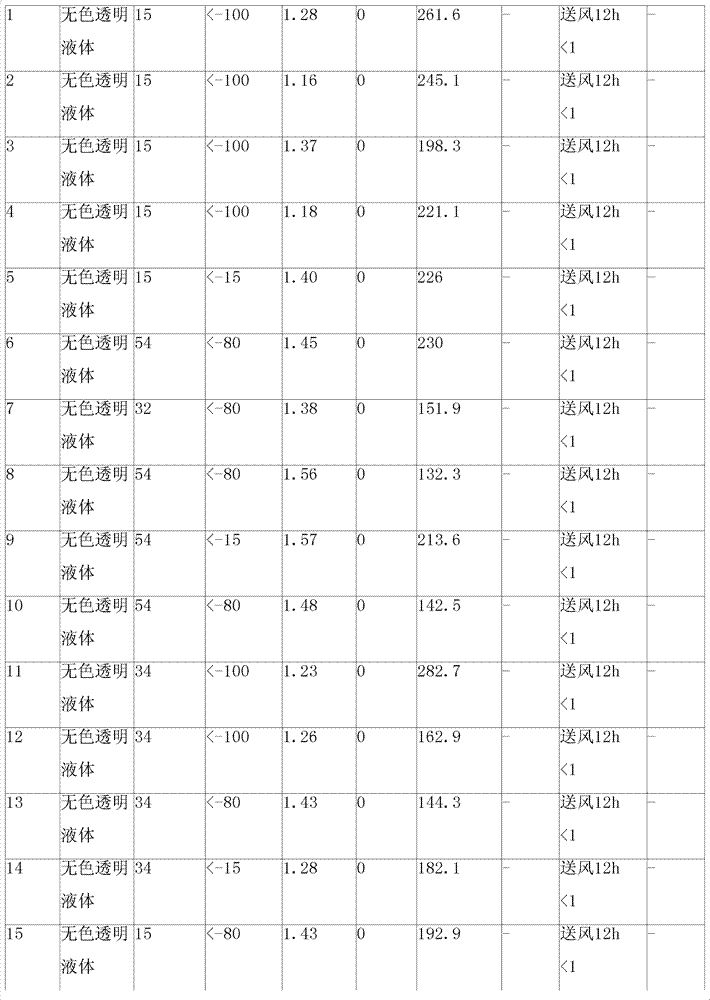

Image

Examples

Embodiment 1

[0023] The mass percentage composition of an environment-friendly shredded tobacco expanding agent composition in this embodiment is: 90% of pentafluoropropane and 10% of ethanol.

[0024] The preparation method is to weigh the raw materials according to the mass percentage of 90% pentafluoropropane and 10% ethanol, then place them in a preparation tank, stir and mix evenly, and then pressurize and filter with a 600-mesh filter to make the Environmentally friendly shredded tobacco expander composition, its technical index data are shown in Table 2.

Embodiment 2

[0026] The mass percentage composition of an environment-friendly shredded tobacco expanding agent composition in this embodiment is: 80% of pentafluoropropane and 20% of isohexane.

[0027] The preparation method is to weigh the raw materials according to the mass percentage of 80% of pentafluoropropane and 20% of isohexane, then place them in a preparation tank, stir and mix evenly, and then pressurize and filter with a 600-mesh filter to prepare the present embodiment. The environment-friendly shredded tobacco expansion agent composition, its technical index data are shown in Table 2.

Embodiment 3

[0029] The mass percentage composition of an environment-friendly shredded tobacco expanding agent composition in this embodiment is: 99% of pentafluoropropane and 1% of diethyl ether.

[0030] The preparation method is to weigh the raw materials according to the mass percentage of 99% pentafluoropropane and 1% diethyl ether, then place them in a preparation tank, stir and mix evenly, and then pressurize and filter with a 600-mesh filter to make the Environmentally friendly shredded tobacco expander composition, its technical index data are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com