Roaster-used milk powder material

A technology for suckling pigs and milk powder, applied in whey, application, dairy products, etc., can solve the problems of reduced protein absorption and effective utilization, difficult protein components to be digested by suckling pigs, immature digestive organs, etc. It is effective in food intake and digestion, promoting rapid intestinal development, and enhancing anti-diarrheal ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The specific preparation process of milk powder for suckling pigs is as follows:

[0024] a. To select corn, its quality indicators should meet: moisture content less than 14%, bulk density greater than 710 g / l, imperfect kernels less than 3%, impurities less than 1%, and no moldy kernels;

[0025] b. Pass the corn through a 20-mesh sieve into coarse powder and then proceed to puffing processing; first set the working temperature of the automatic temperature control device of the extruder to 100°C, and gradually adjust it to 140°C after feeding, and put in corn meal by changing the resistance template Adjust the pressure in the puffing chamber to 3Mpa, control the rotation speed of the extrusion screw at 200r / min, keep the residence time of the material in the puffing chamber at about 20S, adjust the moisture content of the material to 20%, after puffing The corn is crushed for the second time, and the sieve of 1.2+1.2 is used for crushing during the second crushing, so...

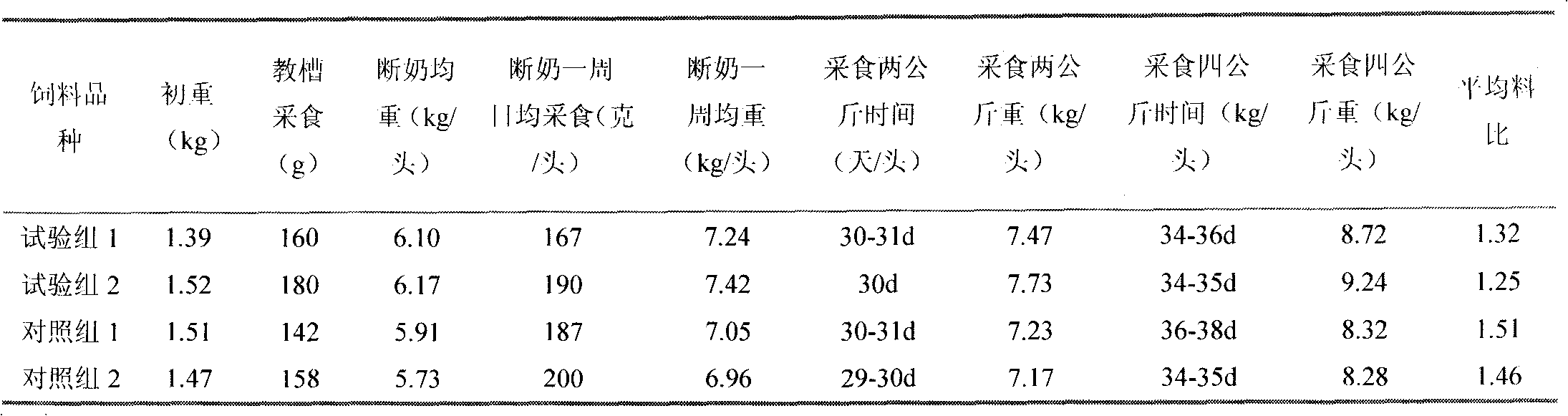

specific Embodiment 2

[0042] Test site: Pujiang Jufeng Pig Farm

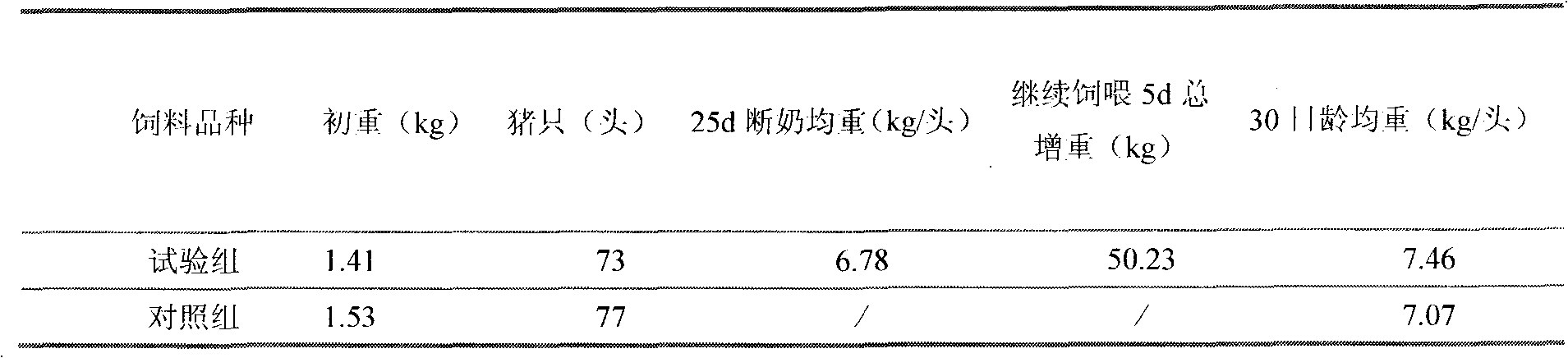

[0043] Experimental design: this test selects 150 suckling piglets with individual uniformity as the test object, and the test is divided into two groups, one group is the test group, and the suckling pig milk powder of the present invention is fed, and the test time is from 5 days old to 5 days after weaning of piglets , 25 days or so of weaning, continue to feed 5 days after weaning, test 73 pigs. Another group is control group, feeds a kind of better milk powder feed (its price is higher than milk powder feed of the present invention 200 yuan / ton) at present commercially available, and test time is piglet 5 days old to 30 days old.

[0044] Test result: see table 2, as can be seen from table 2: feed suckling pig milk powder material of the present invention, even if suckling pig is weaned 5 days ahead of schedule, suckling pig also can reach under the unfavorable condition of weaning and mother-child separation stress. The final ...

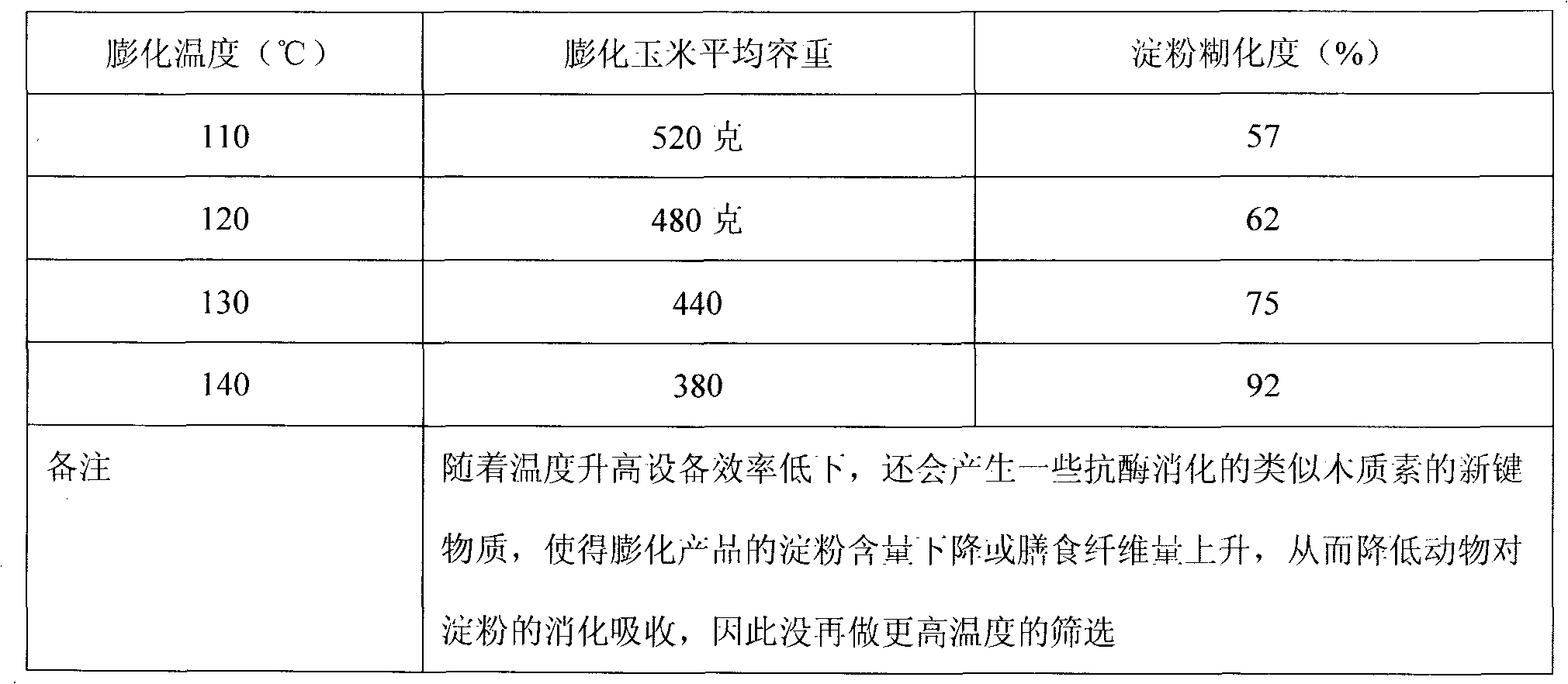

specific Embodiment 3

[0047] In this example, the temperature of corn puffing is screened. Since the starch molecules in the raw corn are aggregated into a dense starch grain structure, there is a considerable proportion of acid-resistant and enzyme-resistant crystal structures in the starch grains, which is not conducive to the digestion and utilization of animals. It must be allowed to Disintegration of the crystal structure (ie gelatinization) can be fully hydrolyzed by enzymes to improve digestibility. When the corn is puffed, the starch is gelatinized, which irreversibly destroys the starch crystal structure, rapidly absorbs water and swells in the animal small intestine, greatly increases the action area and penetration ability of amylase, and improves the hydrolysis speed and digestion degree of starch. At the same time, gelatinized starch greatly improves the sensitivity of α-amylase, making it more rapid. In addition, gelatinized starch can also stimulate the production of lactic acid in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com