Positive thermosensitive CTP version developer solution

A developing solution and heat-sensitive technology, applied in the field of developing solution, can solve the problems that sodium hydroxide strong alkaline substance is irritating and corrosive, affects dot reduction and printing durability, environment and water sources are easy to cause pollution, etc., and achieves good results. Decontamination, improvement of development uniformity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] After degreasing, electrolysis, oxidation, and hydrophilization, the 0.3mm thick aluminum plate base is coated with a positive thermal CTP photosensitive liquid (manufactured by Pingyi Printing Technology Co., Ltd.) to make a positive thermal CTP plate.

[0046]Positive thermal CTP plate is plated by Creo Trendsetter 800II Quantum plate making machine, laser power 12W, imaging drum speed 185rpm. Developing conditions: developing temperature 23°C; developing time 35S; dynamic fluid replenishment 85cc / sqm; static fluid replenishment 85ml / hr; brush speed 60rpm.

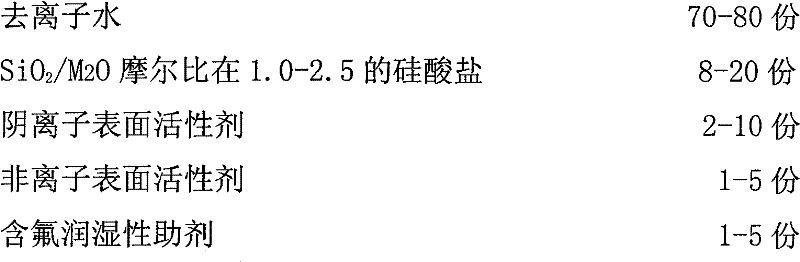

[0047] This example developing solution is the mixture that is made up of following weight ratio composition:

[0048] 73 parts of deionized water

[0049] Sodium silicate 12 parts

[0050] Sodium secondary alkyl sulfonate 5 parts

[0051] Fatty alcohol polyoxyethylene ether 3 parts

[0052] Potassium perfluoroalkyl ether carboxylate 2 parts

[0053] 1 part propylene glycol methyl ether

[0054] Silicone def...

Embodiment 2

[0071] Use a 0.3mm thick aluminum plate base to go through degreasing, electrolysis, oxidation, and hydrophilization, and then apply a positive thermal CTP photosensitive liquid (produced by Pingyi Printing Technology Co., Ltd.) to make a positive thermal CTP plate.

[0072] Positive thermal CTP plate passes through Creo Trendsetter 800II Quantum plate making mechanism with 1%-100% dot image, laser power 12W, imaging drum speed 185rpm. Developing conditions: developing temperature 23°C; developing time 35S; dynamic fluid replenishment 85cc / sqm; static fluid replenishment 85ml / hr; brush speed 60rpm. Use the developer solution of the following weight ratio:

[0073] 80 parts of deionized water

[0074] Sodium silicate 20 parts

[0075] Acrylic acid-maleic acid copolymer 7 parts

[0076] Fatty alcohol polyoxyethylene ether 5 parts

[0077] Potassium perfluoroalkyl ether carboxylate 5 parts

[0078] Propylene glycol methyl ether 2 parts

Embodiment 3

[0102] In this example, the weight ratio of the developer solution components is:

[0103] 75 parts of deionized water

[0104] Sodium silicate 14 parts

[0105] Sodium secondary alkyl sulfonate 6 parts

[0106] Fatty alcohol polyoxyethylene ether 3 parts

[0107] Potassium perfluoroalkyl ether carboxylate 3 parts

[0108] Sodium silicate SiO 2 / Na 2 The molar ratio of O is 1.0

[0109] Using the developing solution of this example, the blank area of the layout is clean, the film retention rate of the photosensitive layer is high, the network dot reduction is good, and the network dots of 1-99% can be reproduced.

[0110] Embodiment 4-6 developer solution composition weight ratio

[0111] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com