Joint protective structure of deep diving electric pump cable and making method thereof

A technology for protecting structures and manufacturing methods, applied to pumps, pump devices, electrical components, etc., can solve the problems of complex sealing and many structural sealing places, and achieve convenient installation and maintenance, good waterproof sealing and insulation, and perfect design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

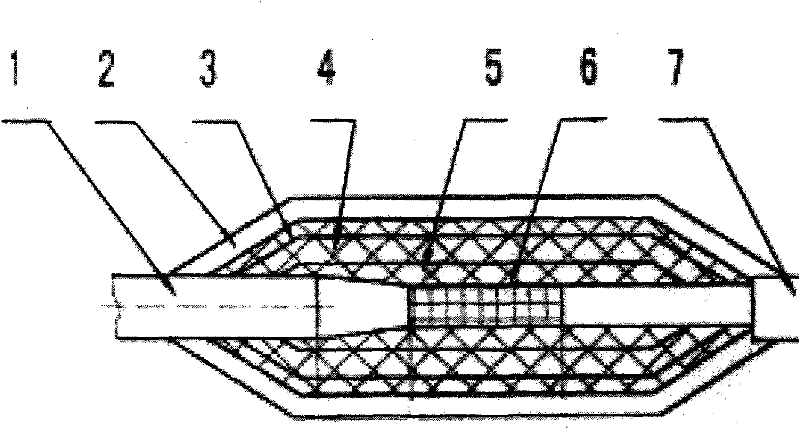

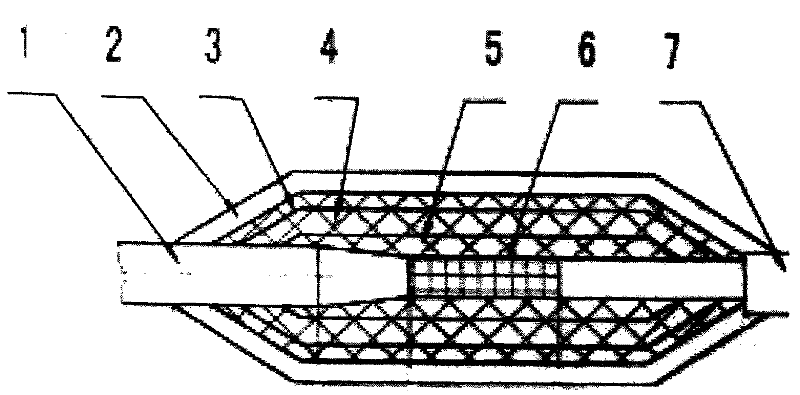

[0021] Such as figure 1 As shown, the joint protection structure of a deep submersible electric pump cable of the present invention includes a high-pressure heat-shrinkable tube 2 and an interconnected power cable 1 and a motor lead-out cable 7 installed in the high-pressure heat-shrinkable tube. The power cable and the motor lead-out cable Teflon tape layer 6 , self-dissolving ethylene propylene rubber tape layer 5 , polyvinyl fluoride tape layer 4 and plastic tape layer 3 are respectively wrapped at the cable connection, from inside to outside to the high-pressure heat shrinkable tube.

[0022] this invention figure 1 The manufacturing method of the joint protection structure of the shown deep submersible electric pump cable is as follows:

[0023] 1) Welding and pretreatment:

[0024] a. Weld the power cable and motor lead-out cable;

[0025] b. Clean up the welding slag on the welding part, file off the sharp corners and burrs;

[0026] c. Scrub the welding surface and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com