Lithium titanate-carbon composite nano-material, preparation method thereof and application thereof

A nano-material, lithium titanate technology, applied in the field of lithium-ion batteries, can solve the problems of increased capacity attenuation, lower rate discharge capacity, and difficult continuous conductive network of lithium-ion batteries, achieving excellent high-current charge and discharge performance and less energy loss , good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Lithium isopropoxide and tetrabutyl titanate are mixed evenly according to the molar ratio of lithium element and titanium element being 4.4:5, and an ethanol solution of polyvinylpyrrolidone K90 is added, and ultrasonically dispersed to form a transparent sol, wherein polyvinylpyrrolidone K90 The dosage is 20% of the total mass of the sol. The prepared transparent sol was electrostatically spun into a film with a thickness of 0.2 mm at a rate of 12 mL / h at a DC voltage of 12.0 kV. Thin film precursors in N 2 Under atmospheric conditions, sinter at 500°C for 30 hours. After cooling, grind and sieve to obtain the lithium titanate-carbon composite nanofiber material provided by the present invention.

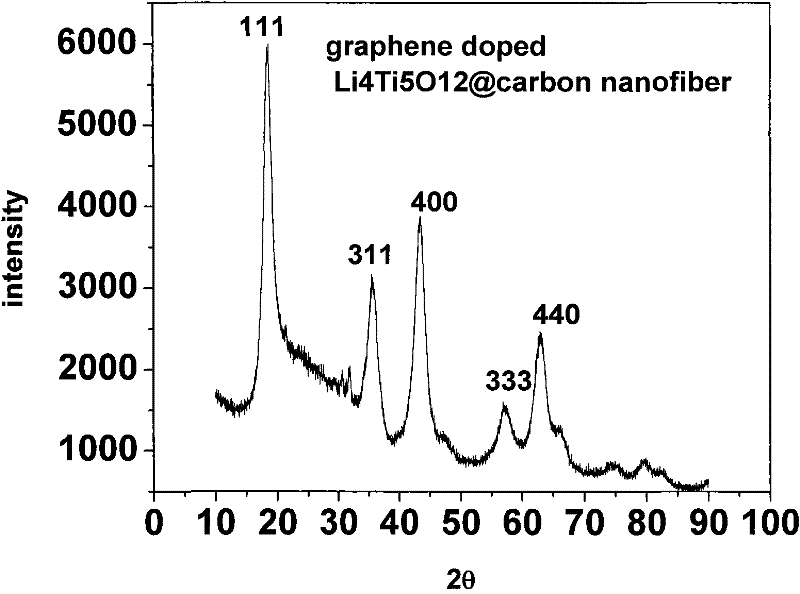

[0043] The aforementioned lithium titanate-carbon composite nanofiber material has a spinel structure. Adopt Cu target Kα radiation, λ=0.15406nm, obtain the X-ray diffraction pattern of this product, as figure 1 shown. pass Figure 4 The field emission scanning electr...

Embodiment 2

[0045] Lithium isopropoxide and tetraisopropyl titanate were uniformly mixed according to the molar ratio of lithium element to titanium element of 5.0:5, and polyaniline (M W 10000~100000) of N-methylpyrrolidone solution and graphene, ultrasonically dispersed to form a transparent sol, wherein the amount of polyaniline is 40% of the total mass of the sol, and the amount of graphene is 1% of the total mass of the sol. The prepared transparent sol was electrostatically spun into a film with a thickness of 0.2 mm at a rate of 2.0 mL / h under a DC voltage of 8.0 kV. Thin film precursors in N 2 Under atmospheric conditions, sinter at 900°C for 3 hours. After cooling, grind and sieve to obtain the lithium titanate-carbon composite nanofiber material provided by the present invention.

[0046] The aforementioned lithium titanate-carbon composite nanofiber material has a spinel structure. Adopt Cu target Kα radiation, λ=0.15406nm, obtain the X-ray diffraction pattern of this produc...

Embodiment 3

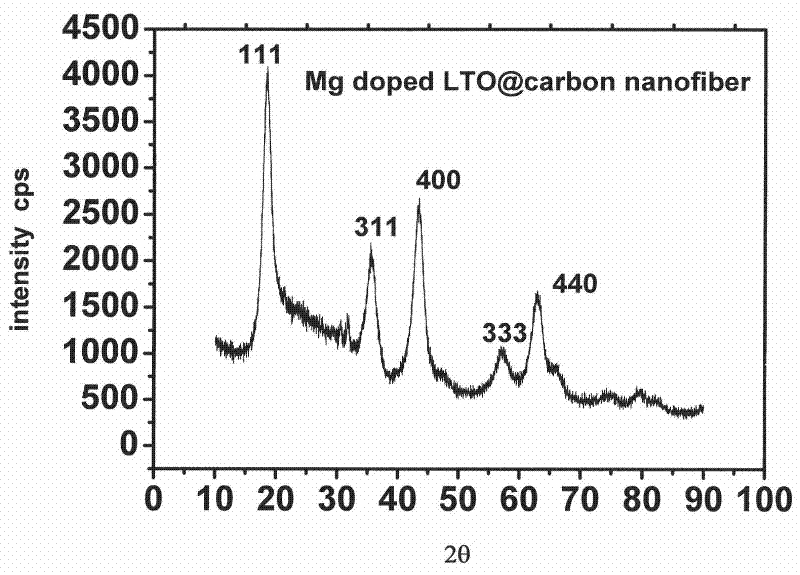

[0048] Lithium isopropoxide, titanium acetylacetonate and magnesium acetate are mixed evenly according to the molar ratio of lithium element, titanium element and magnesium element as 4:5:0.1, and polyacrylonitrile (M W 10000-100000) dimethyl sulfoxide solution, ultrasonically dispersed to form a transparent sol, wherein the amount of polyacrylonitrile is 10% of the total mass of the sol. The prepared transparent sol was electrostatically spun into a film with a thickness of 0.2 mm at a speed of 0.1 mL / h under a DC voltage of 15.0 kV. Thin film precursors in N 2 Under atmospheric conditions, sinter at 650°C for 10 hours. After cooling, grind and sieve to obtain the lithium titanate-carbon composite nanofiber material provided by the present invention.

[0049] The above-mentioned lithium titanate-carbon composite nanofiber material is a composite nanofiber material with a diameter of 100nm and a length of 2-5μm, and its X-ray diffraction diagram and transmission electron mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com