Packaging substrate structure for LED and production method thereof

A technology for packaging substrates and manufacturing methods, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as the large influence of LED chips, the influence of chip luminescence, and limited application occasions, so as to improve light output and light Color distribution, improve light output efficiency and life, improve the effect of work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

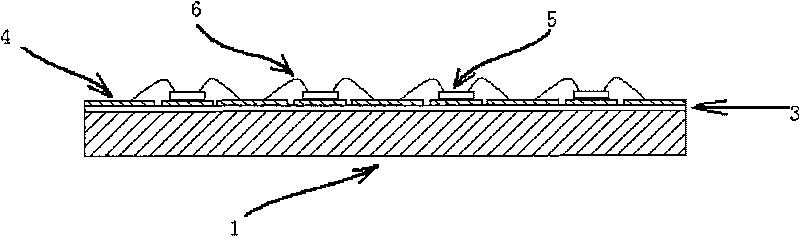

[0034] Embodiment 1: as figure 2 As shown, the substrate and the boss are made of metal materials, and the substrate outside the boss is stacked with an insulating layer 3 and a circuit connection layer 4 of a copper-clad circuit from bottom to top.

[0035]The production method is as follows: when making the metal base plate of the boss, the boss is first formed on the metal plate by stamping, rolling, melting or etching, etc., and according to the size, shape and height of the boss, the designed and manufactured The insulating layer 3 with holes and the circuit connection layer 4 are successively stacked on the metal plate, exposing the boss above the circuit connection layer. The packaged LED chip 5 is bonded on the boss by silver glue bonding or eutectic welding, and then the LED chip 5 is connected to the circuit connection layer 4 by welding gold wire 6 .

Embodiment 2

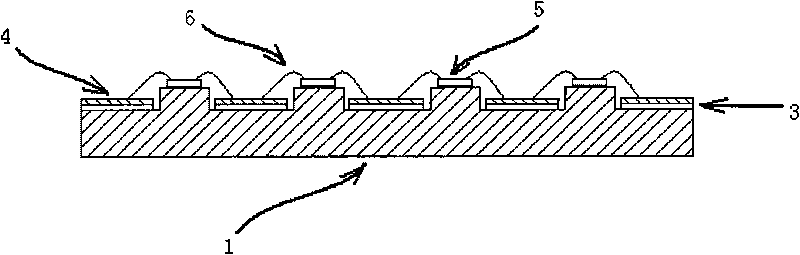

[0036] Embodiment 2: as image 3 Shown is a schematic structural diagram of a ceramic substrate with a boss structure. The substrate and the boss are made of ceramic material, and the circuit connection layer 4 formed by vapor deposition is arranged on the substrate outside the boss.

[0037] The manufacturing method is as follows: for using ceramics as the base plate, by adopting methods such as injection molding, during the sintering process of the ceramics, the bosses with specific size, shape and height are directly formed on the ceramic base plate. Then, the designed circuit connection layer 4 is vapor-deposited on the ceramic substrate. The packaged LED chip is also crystal-bonded or eutectic on the boss of the ceramic substrate, and is electrically connected to the circuit connection layer 4 through the gold wire 6 .

Embodiment 3

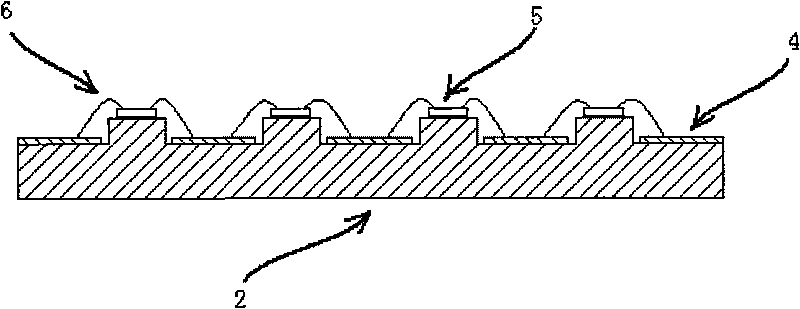

[0038] Embodiment 3: as Figure 4 , 5 As shown, for metal-ceramic hybrid substrates, the difference from the structure of Example 2 is that a hole with a certain size, shape and depth is provided at the position corresponding to the bottom surface of the substrate and the boss, and metal is melted in the hole. Or be filled with silver paste 7 . Furthermore, a metal layer of a certain thickness may be provided on the bottom of the substrate, and the metal layer is connected to the metal melted in the hole or the silver paste injected.

[0039] The production method is as follows: same as in Example 2, also in the process of ceramic sintering, a boss of a specific size is generated on the top surface of the ceramic substrate. The difference is that at the same time, at the position corresponding to the boss on the bottom of the ceramic substrate, Holes of a certain size, shape and depth are left. Then reverse the ceramic substrate, and then melt metal, such as copper, aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com