Annealed wafer and method for producing annealed wafer

An annealing and wafer technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as weak Cu gettering effect, weak gettering effect, and poor device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

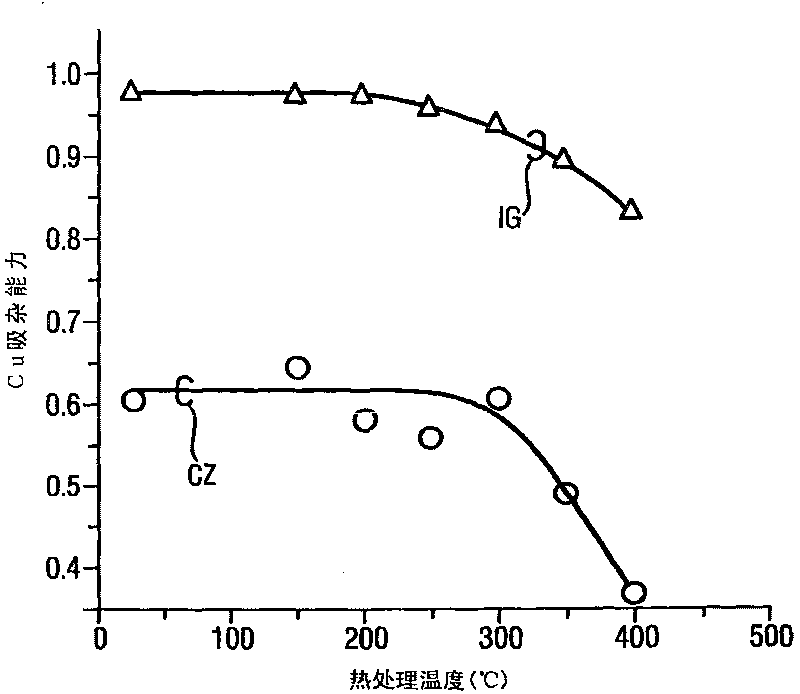

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] By using the CZ method, the nitrogen concentration was pulled up to 3 x 10 15 / cm 3 (measured by SIMS), the carbon concentration is 8×10 15 / cm 3 , and the oxygen concentration is 9×10 17 / cm 3 Silicon single crystal (measured by FT-IR according to JEIDA standard).

[0067] After slicing and polishing the resulting silicon single crystal to obtain mirror wafers (silicon substrates), during the manufacturing process, the mirror wafers were inserted into a furnace at 700 °C under an atmosphere containing nitrogen and oxygen, specifically, nitrogen-based, oxygen-containing The mirror wafer was heat-treated at 700°C for 4 hours in an atmosphere having a concentration of 0.2% by volume, and then pulled out from the furnace.

[0068] Then, the oxide film of the silicon substrate under heat treatment is removed by etching, and the silicon substrate is inserted into a furnace under an argon atmosphere, specifically, 100% argon gas. After heating it from 700°C to 1000°C at...

Embodiment 2

[0072] By using the CZ method, the nitrogen concentration was pulled up to 2 x 10 15 / cm 3 (measured by SIMS), the carbon concentration is 8×10 15 / cm 3 , and the oxygen concentration is 9×10 17 / cm 3 Silicon single crystal (measured by FT-IR according to JEIDA standard).

[0073] After slicing and polishing the resulting silicon single crystal to obtain a mirror wafer (silicon substrate), during the manufacturing process, the mirror wafer is inserted into a furnace at 700°C under an argon atmosphere with an argon concentration of 100%, and the mirror wafer is kept in the furnace 4 hours. Then, it was annealed with argon at 1200° C. for 1 hour by raising the temperature to 1000° C. at a rate of 8° C. / min., and then raising the temperature to 1100° C. at a rate of 4° C. / min. °C, and raised to 1200 °C at a rate of 1 °C / min to pull out the silicon substrate from the furnace.

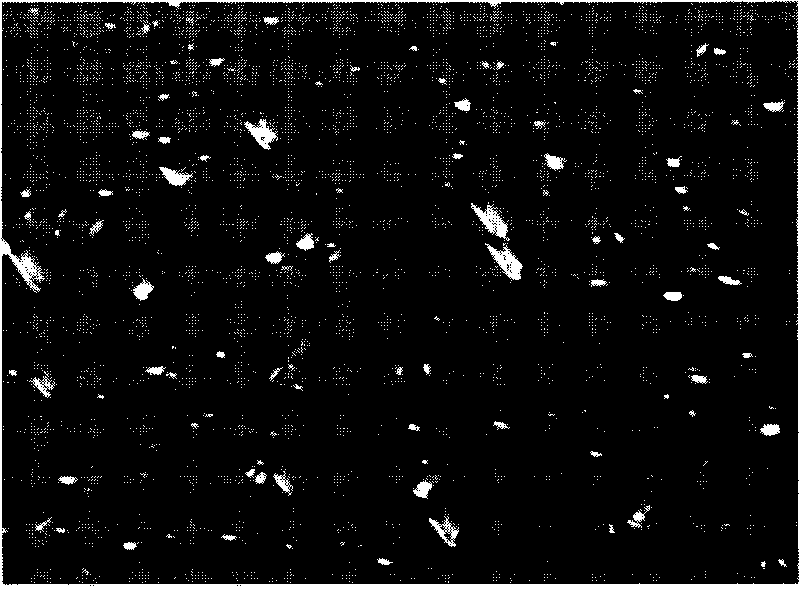

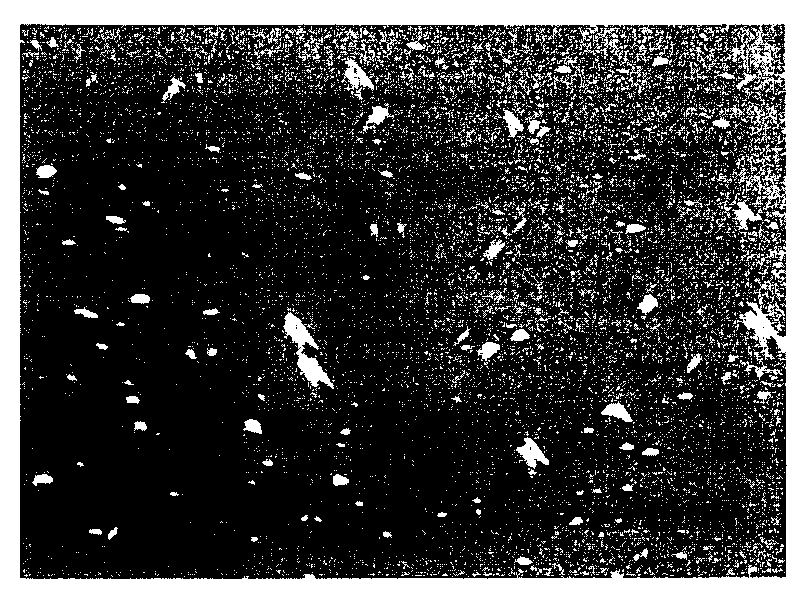

[0074] Observing the internal oxygen deposits after annealing with a transmission electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com