Two-step diffusion pretreatment method for casting single-crystal or polycrystal silicon wafers

A pretreatment, silicon wafer technology, applied in the field of solar cells, can solve the problems of low minority carrier lifetime, high defect density, small angle grain boundaries, etc., to achieve the effect of retaining surface roughness, improving cell efficiency, and improving gettering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

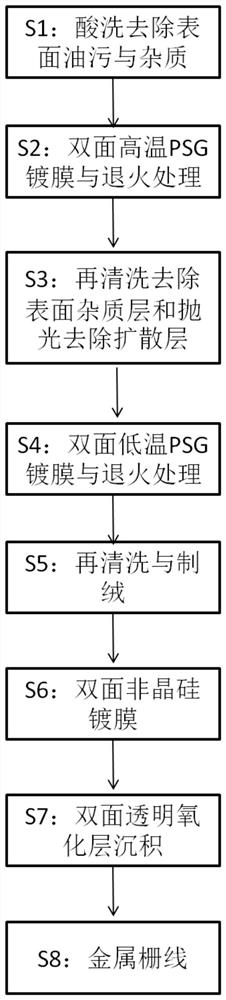

[0021] Such as Figure 2 to Figure 3 Shown is a schematic diagram of an embodiment of a two-step diffusion pretreatment method for a cast single crystal or polycrystalline silicon wafer provided by the present invention.

[0022] A two-step diffusion pretreatment method for casting single crystal or polycrystalline silicon wafers, it comprises the following steps,

[0023] A. Pickling: Pickling the silicon wafer with an acidic solution, then cleaning and drying;

[0024] B. Deposit PSG at high temperature: Deposit a phosphosilicate glass layer at a high temperature on the surface of the silicon wafer after the pickling treatment in step A, and perform annealing treatment;

[0025] C. One-time impurity removal: the silicon wafer after the high-temperature deposition PSG treatment in step B is cleaned and polished wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com