Grease dirt cleaning agent for bituminous pavement and preparation method

A technology of asphalt pavement and cleaning agent, which is applied in the direction of road surface cleaning, cleaning methods, chemical instruments and methods, etc., can solve the problems of affecting driving safety, large social impact, and softening point reduction, and achieves convenient use, environmental friendliness, strong detoxification The effect of oil pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

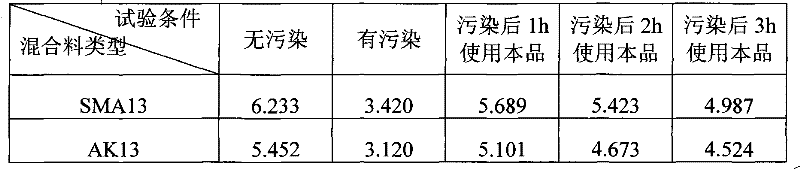

Examples

Embodiment 1

[0026] An asphalt pavement oil stain cleaner is characterized in that it consists of 10 parts of nonionic surfactant, 15 parts of anionic surfactant, 10 parts of ethanol and 65 parts of deionized water in parts by weight.

[0027] The nonionic surfactant is prepared by stirring and emulsifying 6 parts of sodium dodecyl sulfonate and 4 parts of α-olefin sulfonate.

[0028] The anionic surfactant is formed by stirring and emulsifying 7.5 parts of alkyl polyglucoside and 7.5 parts of fatty alcohol polyoxyethylene ether.

[0029] A preparation method of asphalt pavement oil stain cleaner, the method comprises the following steps:

[0030] (1) Mix 6 parts of sodium dodecylsulfonate and 4 parts of α-olefin sulfonate, and emulsify homogeneously for 3 minutes at a stirring speed of 60r / min; after that, high-speed shear emulsification at a speed of 2500r / min 5min, made 10 parts of nonionic surfactant mixed emulsion;

[0031] (2) Mix 7.5 parts of alkyl polyglucoside and 7.5 parts of f...

Embodiment 2

[0034] An asphalt pavement oil stain cleaner is characterized in that it consists of 15 parts by weight of nonionic surfactant, 20 parts of anionic surfactant, 10 parts of ethanol and 55 parts of deionized water.

[0035] The nonionic surfactant is prepared by stirring and emulsifying 9 parts of sodium dodecyl sulfonate and 6 parts of α-olefin sulfonate.

[0036] The anionic surfactant is prepared by stirring and emulsifying 10 parts of alkyl polyglucoside and 10 parts of fatty alcohol polyoxyethylene ether.

[0037] A preparation method of asphalt pavement oil stain cleaner, the method comprises the following steps:

[0038] (1) Mix 9 parts of sodium dodecyl sulfonate and 6 parts of α-olefin sulfonate, and emulsify homogeneously for 5 minutes at a stirring speed of 80r / min; after that, high-speed shear emulsification at a speed of 2500r / min 10min, made 15 parts of nonionic surfactant mixed emulsion;

[0039] (2) Mix 10 parts of alkyl polyglucoside and 10 parts of fatty alco...

Embodiment 3

[0042] An asphalt pavement oil stain cleaner is characterized in that it consists of 10 parts of nonionic surfactant, 20 parts of anionic surfactant, 10 parts of ethanol and 55 parts of deionized water in parts by weight.

[0043] The nonionic surfactant is prepared by stirring and emulsifying 6 parts of sodium dodecyl sulfonate and 4 parts of α-olefin sulfonate.

[0044] The anionic surfactant is prepared by stirring and emulsifying 10 parts of alkyl polyglucoside and 10 parts of fatty alcohol polyoxyethylene ether.

[0045] A preparation method of asphalt pavement oil stain cleaner, the method comprises the following steps:

[0046] (1) Mix 6 parts of sodium dodecyl sulfonate and 4 parts of α-olefin sulfonate, and emulsify homogeneously for 4 minutes at a stirring speed of 70r / min; after that, high-speed shear emulsification at a speed of 2500r / min 8min, made 10 parts of nonionic surfactant mixed emulsion;

[0047] (2) Mix 10 parts of alkyl polyglucoside and 10 parts of fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com