Technological method for municipal wastewater nitrogen and phosphorus removal

A municipal sewage, nitrogen and phosphorus removal technology, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem that water quality is difficult to meet discharge standards, water quality is difficult to remove phosphorus, and there is not much land for use and other problems, to achieve excellent mass transfer characteristics, good biological treatment effect, and rough surface of the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

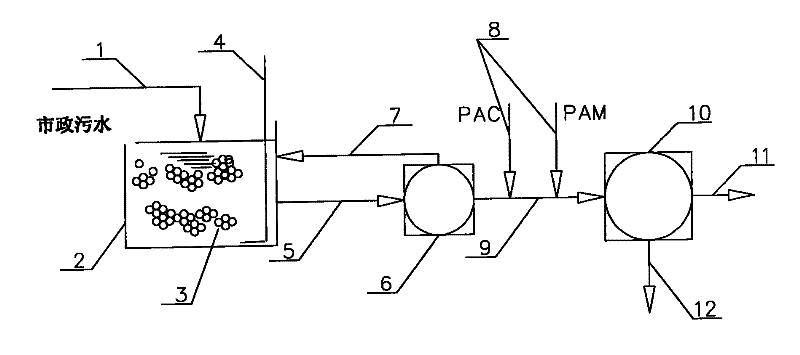

[0022] As shown in the drawings, in this embodiment, the municipal sewage is placed in the bioreactor 2 loaded with microbial magnetic seeds 3 through the water inlet pipe 1 and the pH is adjusted to 9, and the dissolved oxygen in the aeration pipe 4 is 0.8mg / l, and then at a temperature of 20°C, the biological reaction was treated for 36 hours. The loaded microorganism magnetic seed 3 of the present embodiment was loaded with ferric oxide magnetic active carbon of microorganisms, and the concentration was 8500mg / l; after biological reaction treatment The mixed liquid enters the magnetic separator 6 with a magnetic field strength of 1800Gs on the surface of the disk through the self-flowing liquid discharge pipeline 5 at a flow rate of 0.4m / s for separation, and the separated liquid enters the scraper type rare earth disk separation device 10 to continue separation. The magnetically activated sludge formed in the end is returned to the bioreactor 2 through the magnetically act...

Embodiment 2

[0024] As shown in the accompanying drawings, in this embodiment, the municipal sewage is first placed in the bioreactor 2 loaded with microbial magnetic seeds 3 through the water inlet pipe 1, and the pH is adjusted to 7, and the dissolved oxygen in the aeration pipe 4 is 1.8mg / l, then biological reaction treatment at a temperature of 30° C. for 24 hours, the microorganism-loaded magnetic seed 3 put in the present embodiment is a magnetic microorganism carrier, and the preparation of the magnetic microorganism carrier is shown in the preparation method of the magnetic microorganism carrier disclosed in Patent Application No. 200910167879.8, The concentration is 8000mg / l; the mixed liquid after biological reaction treatment enters the magnetic separator 6 with a magnetic field strength of 1500Gs on the surface of the disk through the self-flowing liquid drainage pipe 5 at a flow rate of 0.3m / s for separation, and the separated liquid enters the scraper type Separation continue...

Embodiment 3

[0026]As shown in the drawings, in this embodiment, the municipal sewage is first placed in the bioreactor 2 loaded with microbial magnetic seeds 3 through the water inlet pipe 1, and the pH is adjusted to 6, and the dissolved oxygen in the aeration pipe 4 is 0.5mg / l, then biological reaction treatment at a temperature of 15°C for 46 hours, the loaded microorganism magnetic species 3 in the present embodiment is magnetic foaming polyvinyl alcohol and magnetic polyurethane foaming spheres, and the concentration is 9000mg / l; after biological reaction treatment The mixed liquid enters the magnetic separator 6 with a magnetic field strength of 2000Gs on the surface of the disk through the self-flowing liquid discharge pipeline 5 at a flow rate of 0.5m / s for separation, and the separated liquid enters the scraper type rare earth disk separation device 10 to continue separation. The magnetically activated sludge formed in the end is returned to the bioreactor 2 through the magnetica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com