Preparing method of nano laminar thermoelectric Bi2Se3 compound

A nanosheet and compound technology, which is applied in the fields of nanostructure manufacturing, binary selenium/tellurium compounds, nanotechnology, etc., can solve the problems of complex process, long reaction period, large energy consumption, etc., and achieves simple process and high reaction time. Short, repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

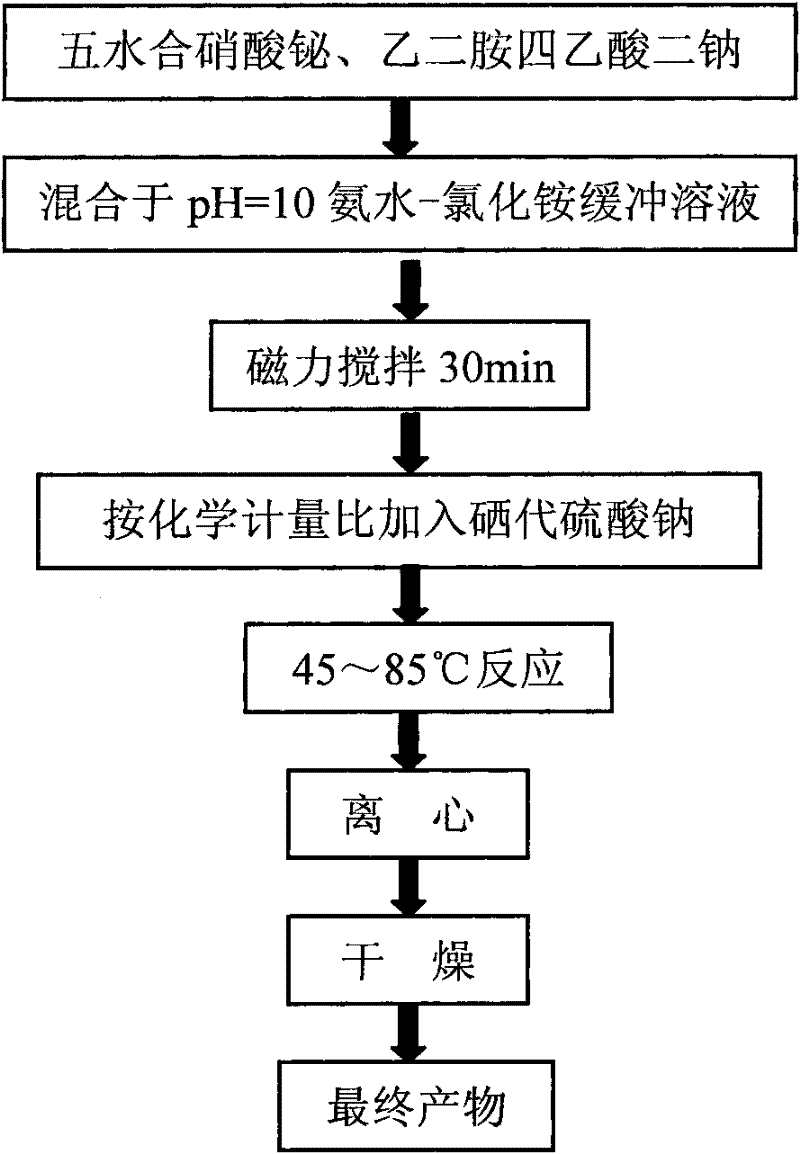

[0021] like figure 1 As shown, the nanosheet Bi 2 Se 3 The preparation method (one-step wet chemical reaction preparation) of thermoelectric compound, it comprises the steps:

[0022] 1) NH with pH=10 3 ·H 2 O-NH 4 Cl buffer solution was used as solvent, Bi(NO 3 ) 3 ·5H 2 O as bismuth source, with C 10 h 14 N 2 Na 2 o 8 2H 2 O is a complexing agent, according to NH 3 ·H 2 O-NH 4 Cl buffer solution: Bi(NO 3 ) 3 ·5H 2 O:C 10 h 14 N 2 Na 2 o 8 2H 2 O=1L: 0.02mol: 0.02mol is batched, mixed, and magnetically stirred for 30min to obtain mixed solution A (Bi is formed in mixed solution A 3+ , metal ion concentration 0.02mol / L, C 10 h 14 N 2 Na 2 o 8 2H 2 O molar concentration is 0.02mol / L);

[0023] 2) With the synthetic sodium selenosulfate as the selenium source, in the mixed solution A according to the chemical formula Bi 2 Se 3 The stoichiometric ratio of sodium selenosulfate was added (i.e. according to Bi(NO 3 ) 3 ·5H 2 Bi in O 3+ : Se in s...

Embodiment 2

[0028] like figure 1 As shown, the nanosheet Bi2 Se 3 The preparation method (one-step wet chemical reaction preparation) of thermoelectric compound, it comprises the steps:

[0029] 1) NH with pH=10 3 ·H 2 O-NH 4 Cl buffer solution was used as solvent, Bi(NO 3 ) 3 ·5H 2 O as bismuth source, with C 10 h 14 N 2 Na 2 o 8 2H 2 O is a complexing agent, according to NH 3 ·H 2 O-NH 4 Cl buffer solution: Bi(NO 3 ) 3 ·5H 2 O:C 10 h 14 N 2 Na 2 o 8 2H 2 O=1L: 0.02mol: 0.02mol is batched, mixed, and magnetically stirred for 30min to obtain mixed solution A (Bi is formed in mixed solution A 3+ , metal ion concentration 0.02mol / L, C 10 h 14 N 2 Na 2 o 8 2H 2 O molar concentration is 0.02mol / L);

[0030] 2) With the synthetic sodium selenosulfate as the selenium source, in the mixed solution A according to the chemical formula Bi 2 Se 3 The stoichiometric ratio of sodium selenosulfate was added (i.e. according to Bi(NO 3 ) 3 · 5 h 2 Bi in O 3+ : Se in ...

Embodiment 3

[0035] like figure 1 As shown, the nanosheet Bi 2 Se 3 The preparation method (one-step wet chemical reaction preparation) of thermoelectric compound, it comprises the steps:

[0036] 1) NH with pH=10 3 ·H 2 O-NH 4 Cl buffer solution was used as solvent, Bi(NO 3 ) 3 ·5H 2 O as bismuth source, with C 10 h 14 N 2 Na 2 o 8 2H 2 O is a complexing agent, according to NH 3 ·H 2 O-NH 4 Cl buffer solution: Bi(NO 3 ) 3 ·5H 2 O:C 10 h 14 N 2 Na 2 o 8 2H 2 O=1L: 0.02mol: 0.02mol is batched, mixed, and magnetically stirred for 30min to obtain mixed solution A (Bi is formed in mixed solution A 3+ , metal ion concentration 0.02mol / L, C 10 h 14 N 2 Na 2 o 8 2H 2 O molar concentration is 0.02mol / L);

[0037] 2) With the synthetic sodium selenosulfate as the selenium source, in the mixed solution A according to the chemical formula Bi 2 Se 3 The stoichiometric ratio of sodium selenosulfate was added (i.e. according to Bi(NO 3 ) 3 · 5 h 2 Bi in O 3+ : Se i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com