Cutter wheel for cutting brittle material and processing method thereof

A brittle material and cutter wheel technology, applied in stone processing equipment, stone processing tools, metal processing, etc., can solve the problem of not being able to remove areas with a certain depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

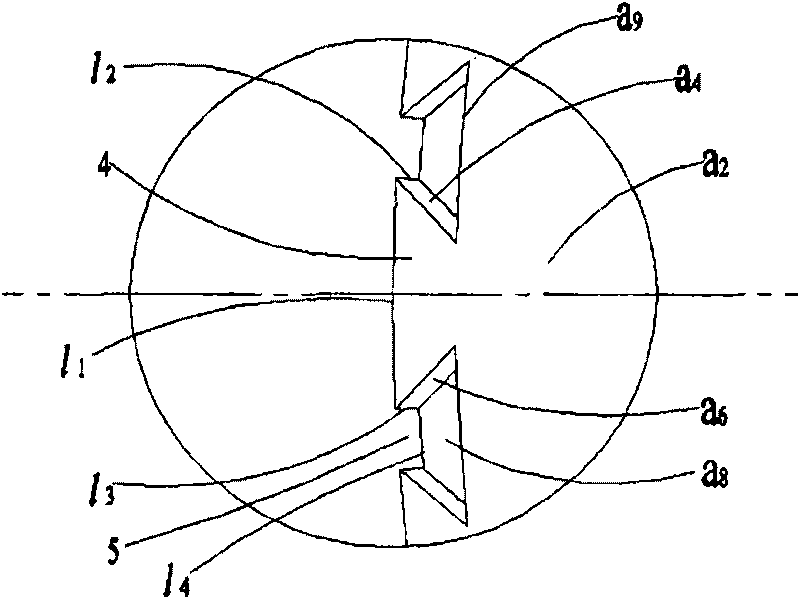

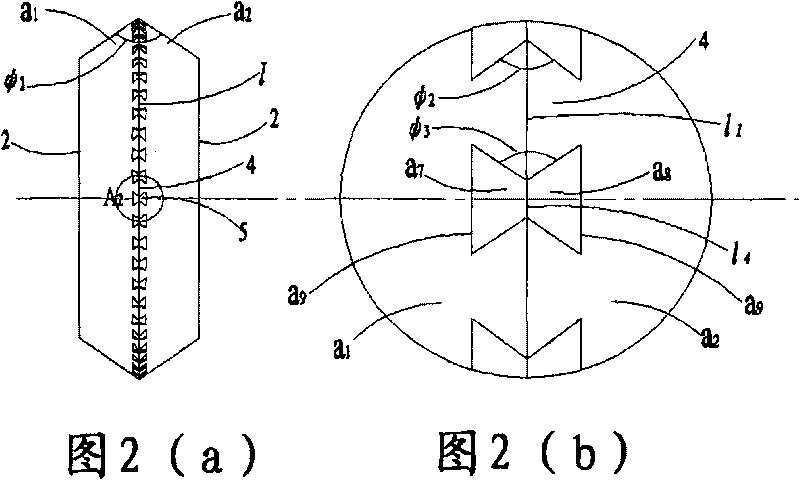

[0081] A cutter wheel for cutting brittle materials and its processing method according to the present invention will be described in detail below with reference to FIGS. 1 to 5 .

[0082] A disc-shaped cutter wheel capable of cutting brittle materials, especially glass materials with a thickness of 0.1 mm to 2 mm, according to the present invention is mainly obtained by processing a special microstructure at the V-shaped cutting edge of a commonly used cutter wheel. A cutter wheel with a new structure.

[0083] The material of the cutter wheel is polycrystalline or polycrystalline diamond, or it can be diamond, cemented carbide, or a composite of these materials; the thickness of the cutter wheel is 0.3mm-5mm, and its typical thickness is 0.7mm; The diameter range of the wheel is 1mm-25mm, of which the typical diameter is 2.5mm; the diameter range of the central shaft hole is 0.2mm-20mm, of which the typical diameter is 0.8mm; the included angle ψ of the V-shaped cutting edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com