Treatment method of acid gas in process of recovering ethylene from refinery dry gas

A technology of refinery dry gas and treatment method, applied in the field of gas purification, can solve the problems of long process flow and waste lye generation, and achieve the effects of simplifying the process, reducing system energy consumption, and reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

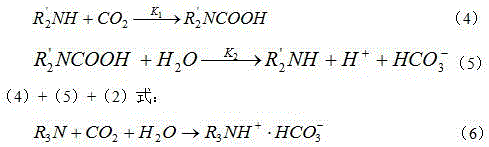

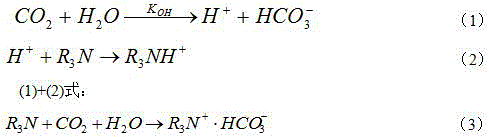

Method used

Image

Examples

Embodiment 1

[0027] The catalytic dry gas of a refinery unit is 32t / h, and the pressure is 1.1MPa, of which, H 2 S ~ 0.8% (vt) and CO 2 ~3.2% (vt), after the amine solution of the present invention (MDEA2.0mol / l, cyclic amine 0.4mol / l) is treated by an absorption tower, the H in the gas 2 S≤5μL.L -1 , CO 2 ≤50μL.L -1 .

Embodiment 2

[0031] After changing the absorption liquid in the comparative example to the absorption liquid of the present invention (MDEA2.3mol / l, cyclic amine 0.3mol / l), the circulation volume of the solution drops to 9 t / h, which greatly reduces the regeneration load of the amine liquid , has a significant energy-saving effect; H in the concentrated gas is extracted after amine washing 2 S≤5μL.L -1 , CO 2 ≤50μL.L -1 . , Eliminate the alkali washing process, reduce the alkali consumption of the ethylene plant alkali washing process, and reduce the discharge of spent alkali.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com