Nano-gold catalyst for deeply removing carbon monoxide, preparing method and application thereof

A carbon monoxide and catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of insufficient ability, short catalyst life, and poor stability of Au catalyst and other problems, to achieve good low-temperature activity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

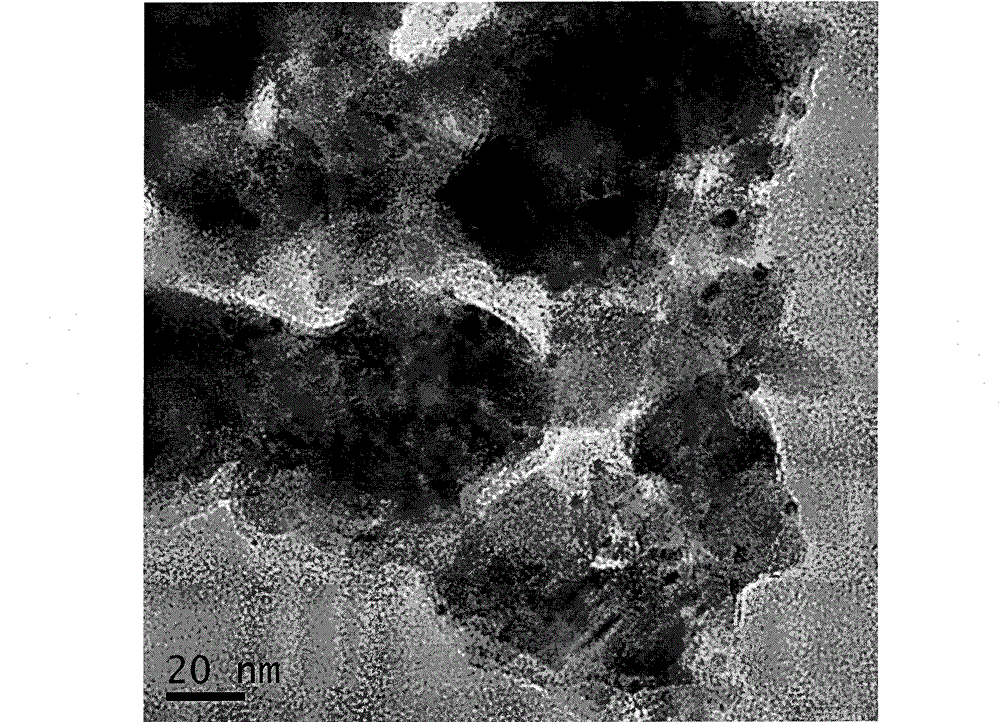

Image

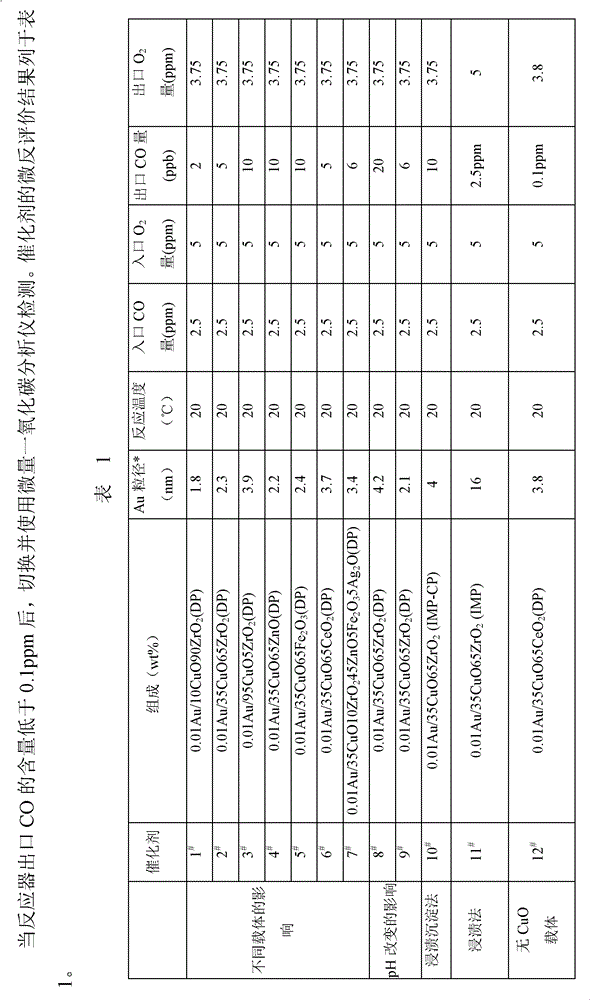

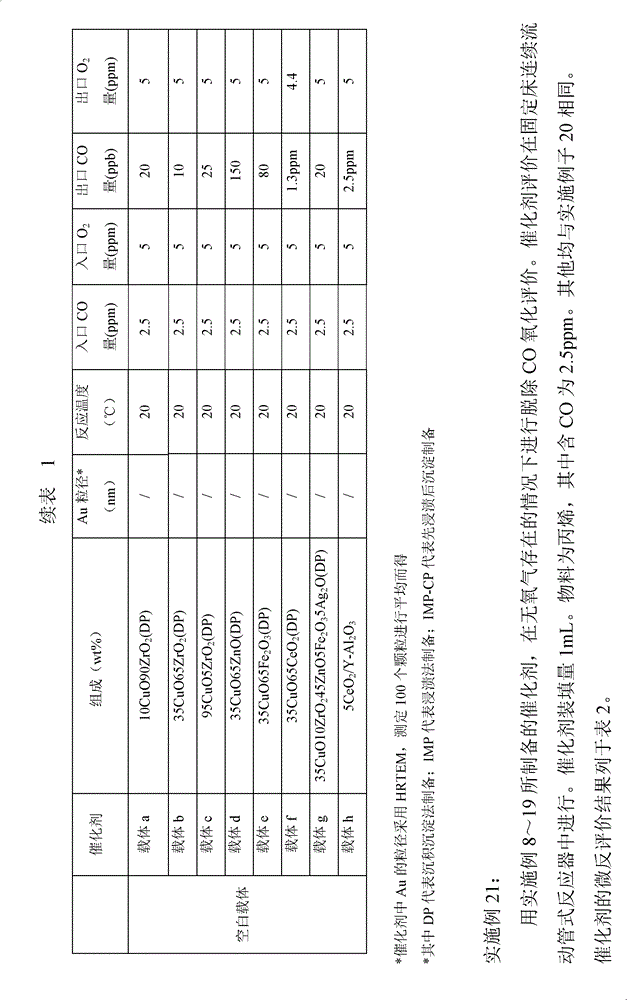

Examples

Embodiment 1~7

[0053] Embodiment 1~7: carrier preparation

[0054] Mix an appropriate amount of 1 mole / liter copper nitrate solution with a certain amount of 1 mole / liter zirconium nitrate solution, 1 mole / liter zinc nitrate solution, 1 mole / liter silver nitrate solution, and 1 mole / liter iron nitrate solution. solution, 1 mol / L manganese nitrate solution, and 1 mol / L cerium nitrate solution to prepare a mixed solution, and then add the mixed solution and 1 mol / L sodium carbonate solution in parallel to a 20L container for precipitation , the precipitation temperature is 50°C, and the pH value is controlled at 8.5±0.5. Then it was aged for 2 hours under vigorous stirring, and the aging temperature was 60°C. It was then filtered and washed at least six times with deionized water at 80 °C until Na 2 The O content is less than 0.05%. Dry at 110°C for 12 hours, and bake at 400°C for 6 hours. Produced containing CuO / ZrO 2 (10 / 90), CuO / ZrO 2 (35 / 65), CuO / ZrO 2 (95 / 5), CuO / ZnO(35 / 65), CuO / Fe...

Embodiment 8~14

[0056] Take 100mL carriers A~G respectively, the particle size is 40~60 mesh, add 0.1mol / L NaOH aqueous solution to adjust 1.0×10 -4 The pH value of the mol / L chloroauric acid solution is 7, the solution temperature is maintained at 60°C, and stirred for 15 minutes; add the carrier while stirring, impregnate the carrier, and then add 0.1mol / L NaOH solution to adjust the pH value to 7 , stirred for 120min, soaked in 0.1mol / L dilute ammonia water for half an hour, then washed 6 times with deionized water at 70°C to remove Cl - to dozens of ppm, then dried at 80°C for 12 hours, and fired at 350°C for 6 hours. 0.01wt% Au / CuO catalysts 1-7 were prepared respectively # .

Embodiment 15

[0058] Take 100mL carrier B with a particle size of 40-60 mesh, add 0.1mol / L NaOH solution to adjust the pH value of the above-mentioned chloroauric acid solution to 6, and keep the solution temperature at 80°C. Others are the same as in Examples 8-14. 0.01wt% Au / catalyst 8 was prepared # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com