Trichlorosilane impurity removal method, polycrystalline silicon material and trichlorosilane impurity removal system

A technology of trichlorosilane and fillers, applied in chemical instruments and methods, silicon compounds, halosilanes, etc., can solve problems such as difficult removal of trichlorosilane impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

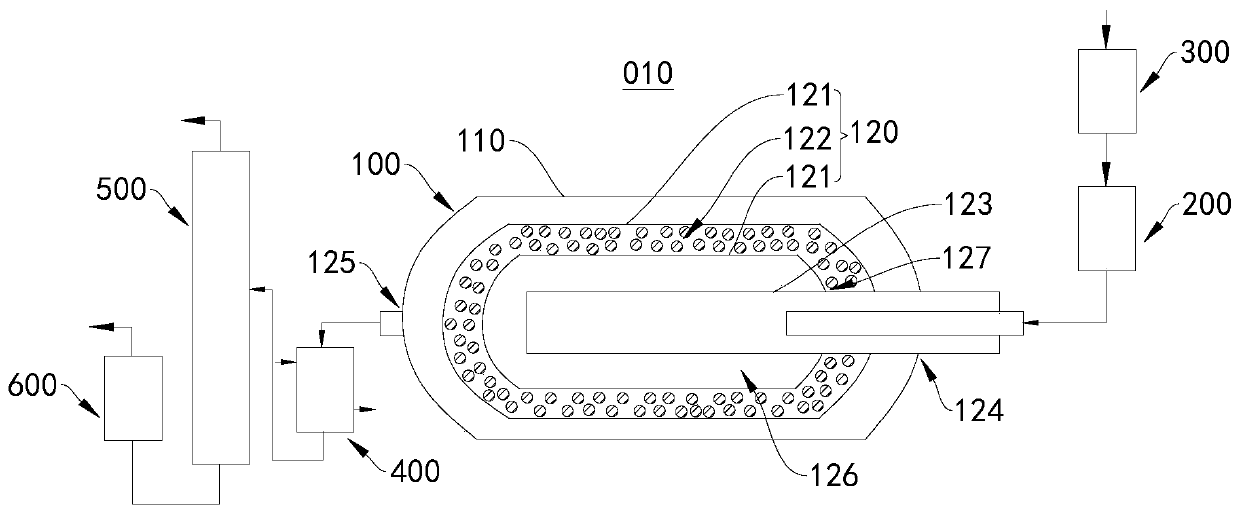

[0061] The trichlorosilane raw material containing dimethyl monochlorosilane to be removed is passed through the first filter 300 to remove solid phase impurities.

[0062] Then pass through the heater 200 to heat the trichlorosilane to be removed to 200°C.

[0063] The heated trichlorosilane is passed into the metal impurity removal reactor 100 filled with platinum (Pt) with an average particle diameter of 1.5mm as the metal impurity removal filler, and the metal is removed by the electric heating tube 123 in the metal impurity removal reaction. The trichlorosilane in the impurity reactor 100 is heated to 500° C., and the pressure of the raw material to be removed is 1 MPa.

[0064] The tail gas reacted in the metal impurity removal reactor 100 is passed into the cooler 400. The tube side medium of the cooler 400 is the reaction tail gas, and the shell side medium is silicon tetrachloride, and the tail gas is cooled to 100°C.

[0065] The cooled tail gas is passed into the r...

Embodiment 2

[0068] The trichlorosilane raw material containing dimethyl monochlorosilane to be removed is passed through the first filter 300 to remove solid phase impurities.

[0069] Then pass through the heater 200 to heat the trichlorosilane to be removed to 600°C.

[0070] The heated trichlorosilane is fed into the metal impurity removal reactor 100 filled with gold (Au), nickel (Ni) and cobalt (Co) with an average particle diameter of 0.1mm as the metal impurity removal filler, and the metal impurity removal The electric heating tube 123 in the reaction heats the trichlorosilane in the metal impurity removal reactor 100 to 600° C., and the pressure of the raw material to be removed is 10 MPa.

[0071] The tail gas reacted in the metal impurity removal reactor 100 is passed into the cooler 400. The tube side medium of the cooler 400 is the reaction tail gas, and the shell side medium is silicon tetrachloride, and the tail gas is cooled to 200°C.

[0072] The cooled tail gas is passe...

Embodiment 3

[0075] The trichlorosilane raw material containing dimethyl monochlorosilane to be removed is passed through the first filter 300 to remove solid phase impurities.

[0076] Then pass through the heater 200 to heat the trichlorosilane to be removed to 100°C.

[0077] The heated trichlorosilane is fed into the metal impurity removal reactor 100 filled with ruthenium (Ru), palladium (Pd) and zirconium (Zr) with an average particle diameter of 2mm as the metal impurity removal filler, and the metal impurity removal reaction The electric heating tube 123 inside heats the trichlorosilane in the metal impurity removal reactor 100 to 300° C., and the pressure of the raw material to be removed is 0.1 MPa.

[0078] The tail gas reacted in the metal impurity removal reactor 100 is passed into the cooler 400. The tube side medium of the cooler 400 is the reaction tail gas, and the shell side medium is silicon tetrachloride, and the tail gas is cooled to 40°C.

[0079] The cooled tail gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com