Improved high-precision numerical control machine

A CNC machine tool, high-precision technology, applied in the direction of large fixed members, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve the problems of scratched surface quality, unstable surface quality, low degree of automation, etc., to achieve surface Good quality, convenient and quick replacement, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

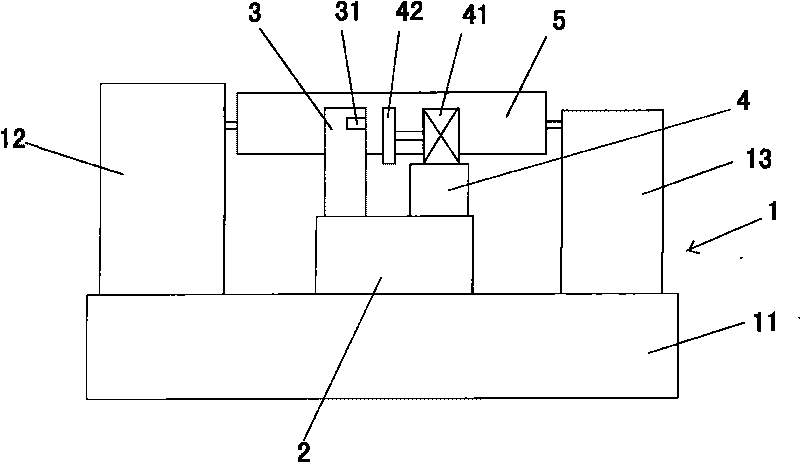

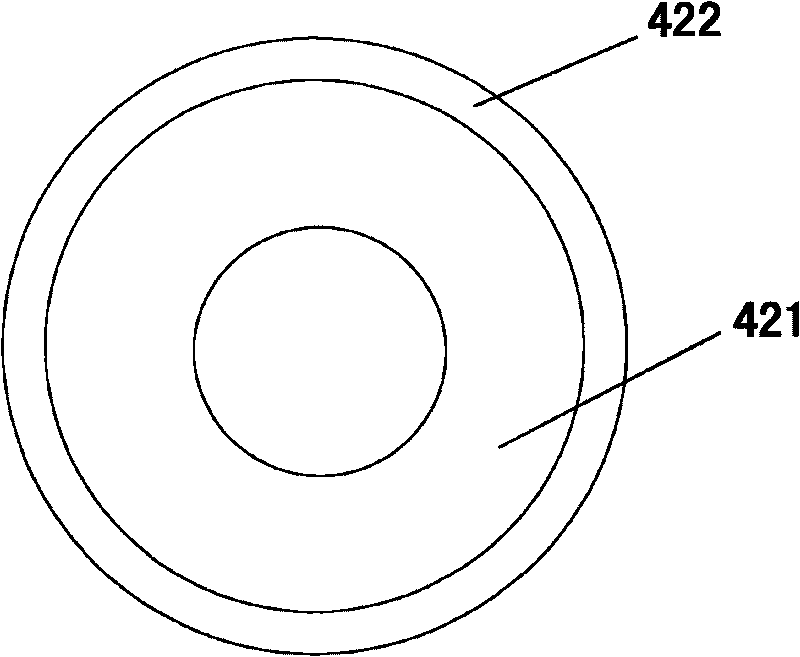

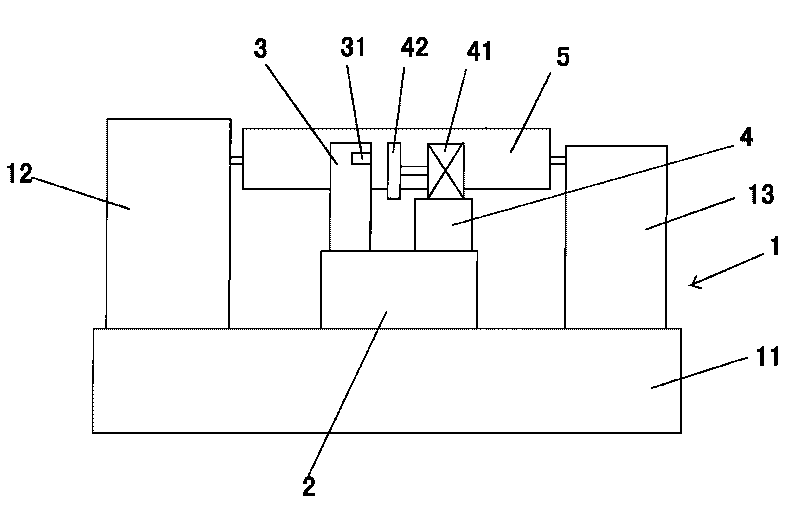

[0025] see figure 1 , refer to figure 2 , the improved high-precision CNC machine tool of the present invention comprises a high-precision CNC lathe body 1, a movable slide plate 2 is installed on the bed 11 of the lathe, and a turning tool holder 3 and a grinding and polishing process are installed side by side on the slide plate 2. Mechanism 4, turning tool 31 is installed on turning tool rest 3, grinding and polishing processing mechanism 4 comprises the motor 41 that is installed on the slide plate 2 and the grinding and polishing head 42 that is installed on the motor main shaft, and grinding and polishing head 42 is made of grinding wheel 421 and The abrasive belt circle 422 that is set on the grinding wheel is formed. The grinding wheel 421 is a highly elastic vulcanized rubber product. figure 1 As shown in , 12 is the headstock, 13 is the tailstock, and 5 is the processing target roller clamped between the headstock and the tailstock.

[0026] The processing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com