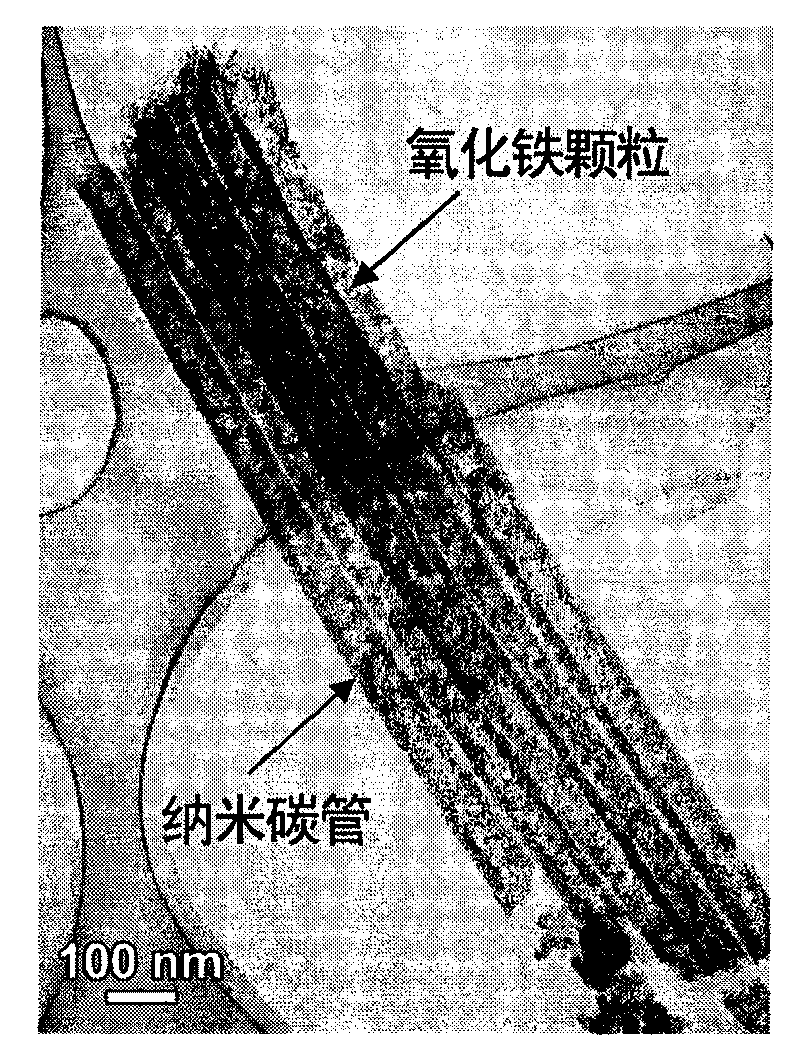

Method for selectively filling ferric oxide particles in hollow cavity of carbon nanotube

A technology of iron oxide particles and carbon nanotubes, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. Filling etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In 3wt% oxalic acid aqueous solution, an aluminum sheet is used for the cathode, and an aluminum sheet is used for the anode, and anodic oxidation is performed at 20°C and 40V to prepare an anodic aluminum oxide film with one end open. After the anodic aluminum oxide film is dried, chemical vapor deposition of acetylene gas is carried out at 600°C for 0.5 hours, the carrier gas is argon, the flow rate is 300ml / min, the heating rate is 5°C / min, the volume concentration of acetylene gas is 1.5%, and the carbon layer is deposited The thickness is 2 nm. The anodic aluminum oxide film after carbon deposition was placed in a ferric nitrate solution with a concentration of 30wt%, and was taken out after ultrasonic vibration for 2 hours. After cleaning the surface, it was dried in the air at 140°C for 6 hours, and then dried at 5°C / min under an argon atmosphere. The rate was increased to 350 °C, and the temperature was maintained for 3 hours. After cooling to room temperature,...

Embodiment 2

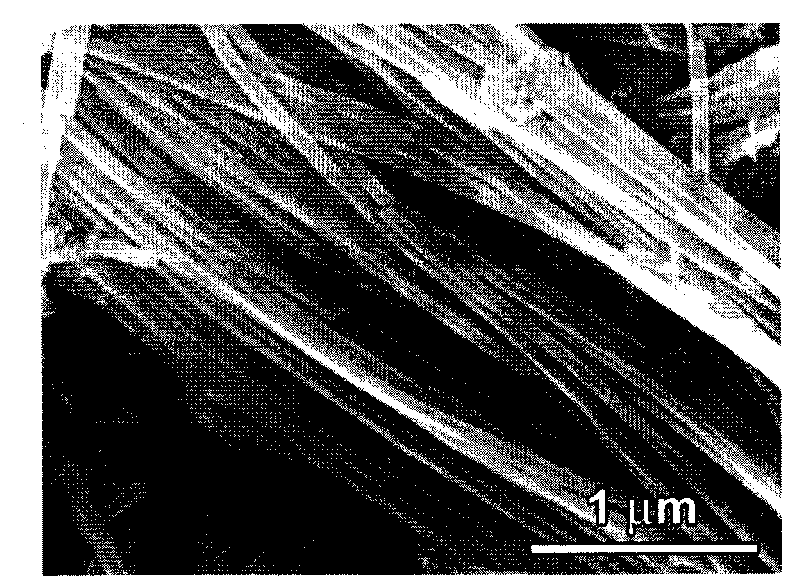

[0023] The preparation method of the anodic aluminum oxide film is the same as in Example 1. After the anodic aluminum oxide film was dried, chemical vapor deposition of acetylene gas was carried out at 700°C for 5 hours, the carrier gas was nitrogen, the flow rate was 300ml / min, the heating rate was 5°C / min, the volume concentration of acetylene gas was 5%, and the carbon layer was deposited The thickness is 20 nm. The anodic aluminum oxide film after carbon deposition was placed in a ferric nitrate solution with a concentration of 25wt%, and was taken out after ultrasonic vibration for 0.5 hours. After cleaning the surface, it was dried in vacuum at 60°C for 2 hours, and then heated at 30°C / min under an argon atmosphere. The rate was increased to 350°C and the temperature was held for 1 hour. After cooling to room temperature, the anodic aluminum oxide film is removed to obtain carbon nanotubes with iron oxide particles completely filling the hollow lumen. like figure 2 ...

Embodiment 3

[0025] In 10wt% sulfuric acid aqueous solution, an aluminum sheet is used for the cathode and an aluminum sheet is used for the anode, and anodic oxidation is performed at 10°C and 20V to prepare an anodic aluminum oxide film with one end open. After the anodic aluminum oxide film is dried, carry out chemical vapor deposition of acetylene gas at 600°C for 0.5 hours, the carrier gas is argon, the flow rate is 200ml / min, the heating rate is 5°C / min, the volume concentration of acetylene gas is 5%, and the carbon layer is deposited The thickness is 5 nm. The anodic aluminum oxide film after carbon deposition was placed in a ferric nitrate solution with a concentration of 25wt%, and was taken out after ultrasonic vibration for 3 hours. After cleaning the surface, it was dried at 140°C for 3 hours in an air atmosphere, and then dried at 10°C / m in an argon atmosphere. The rate of min was increased to 350°C, and the temperature was kept constant for 3 hours. After cooling to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com