Method for improving brightness of LED chip

A technology of LED chips and brightness, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large difference in refractive index and inability to export chips, etc., and achieve the effect of improving light extraction efficiency, brightness, and increasing the probability of escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Take the 10*23mil chip as an example below to specifically illustrate the implementation process of the method of the present invention:

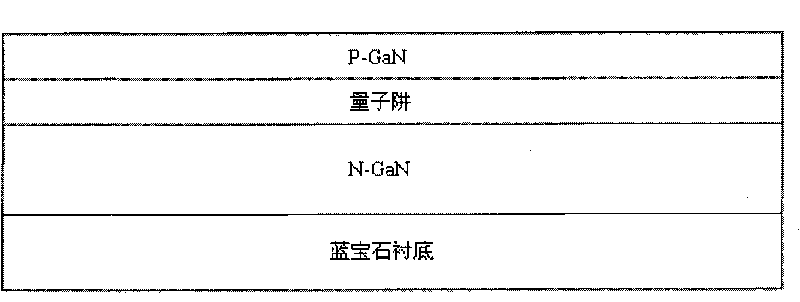

[0023] Step 1, utilize metal-organic chemical vapor deposition technique to grow GaN (gallium nitride) semiconductor layer on sapphire substrate, this layer comprises N-GaN layer, quantum well and P-GaN layer, as Figure 1A shown.

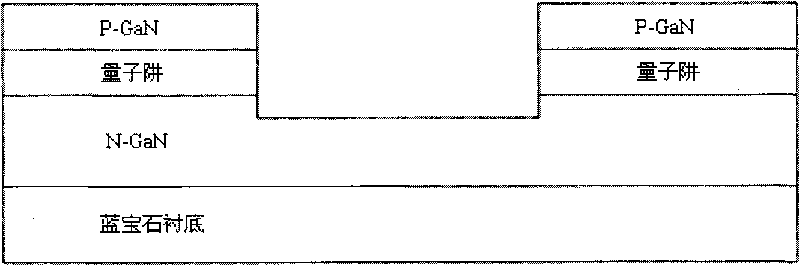

[0024] Step 2, using ICP Etching (Inductively Coupled Plasma Etching) or RIE (Reactive Ion Etching) technology to expose part of the N-GaN layer, and the etching depth is ,Such as Figure 1B Shown; In a specific embodiment, the etching depth is .

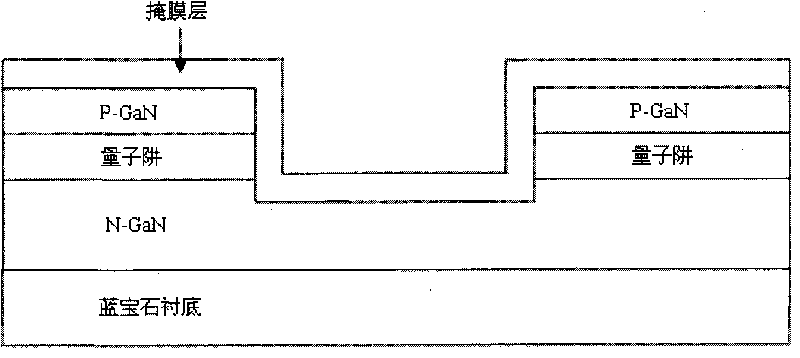

[0025] Step 3, vapor-depositing a metal layer Ni / Ag on the GaN semiconductor layer with a thickness of , the plating rates are , , using this metal layer as a mask layer, such as Figure 1C shown.

[0026] The metal layer is divided into two layers, the adhesion layer is in contact with the GaN layer, and the protection layer is in contact with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com