Smelting palletizing shaft furnace air-guiding wall and building method thereof

A technology of air guide wall and shaft furnace, which is applied to furnaces, vertical furnaces, furnace components, etc., which can solve the problems of troublesome handling of frame-shaped refractory bricks, short service life of air guide walls, and difficulty in replacement, so as to increase the number of pellets Large output and supporting force, easy to manufacture and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

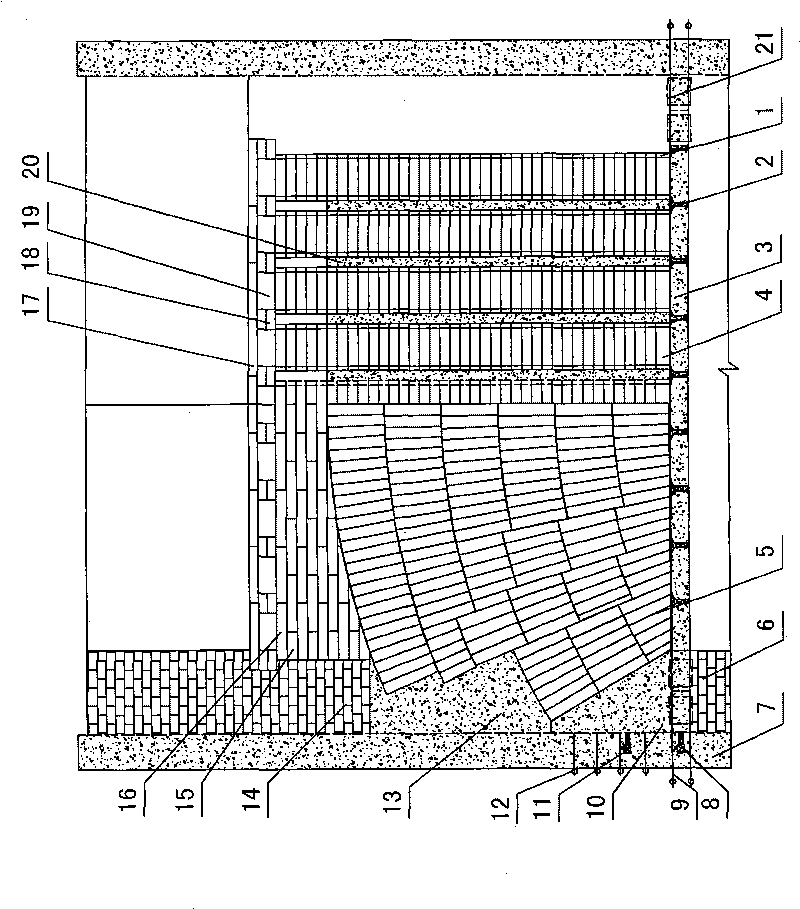

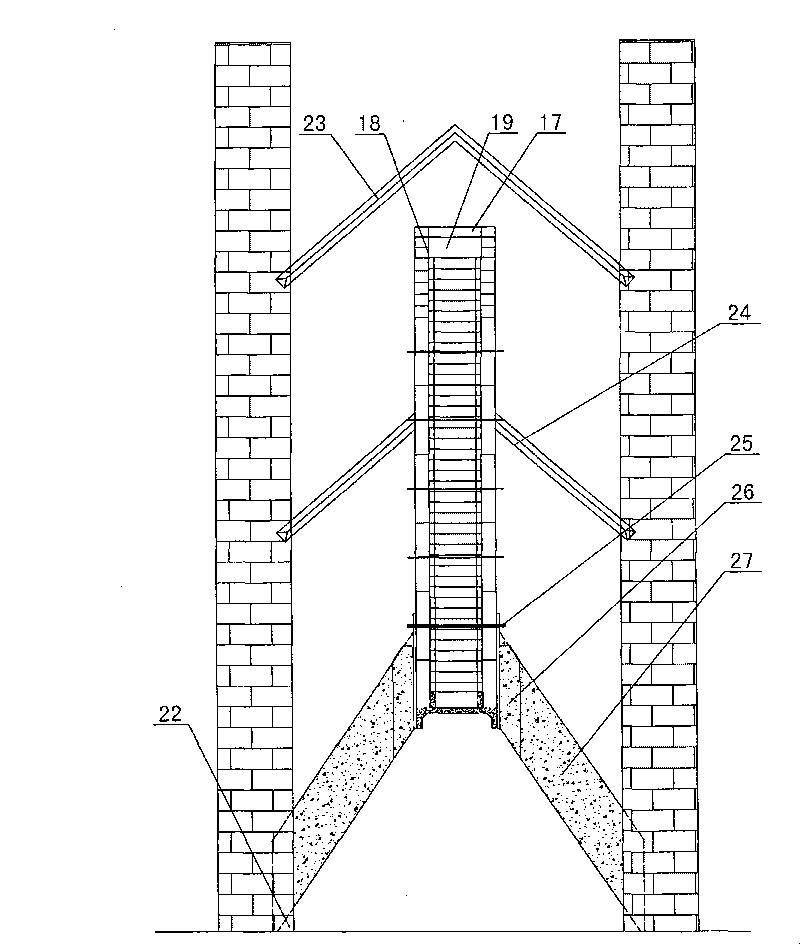

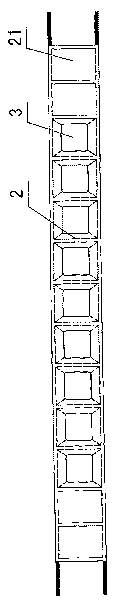

[0032] The invention will be further described below in conjunction with the accompanying drawings.

[0033] This embodiment is a kind of smelting pellet shaft furnace wind guide wall, see figure 1, the wind guide wall is built with several layers of vertical wedge-shaped bricks, 5 staggered stools, semicircular or arched, into a flat or arched shape with an upper arch and a lower arch, and arch angles 10 or water arch angles made of heat-resistant metal are set at both ends, It is built by laying bricks or stones on the top of the pad 21 in the pad brick hole at the two ends of the bottom bracket. And from here, according to the prefabricated first ring of vertical wedge-shaped bricks 5 of different lengths, they are built on the heat-resistant metal bottom bracket 2 of the wind-guiding wall supporting device according to the arrangement sequence of arched and staggered stools, forming an upper arch and a lower flat. shape. The heat-resistant metal bottom support 2 is a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com