Low-cost inside diameter-variable combustion chamber and design and test method thereof

A design method and combustion chamber technology, applied in the field of combustion chambers, can solve problems such as low cost, inapplicability, and heavy weight, and achieve the effects of low structural cost, wide application range, and high cost ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

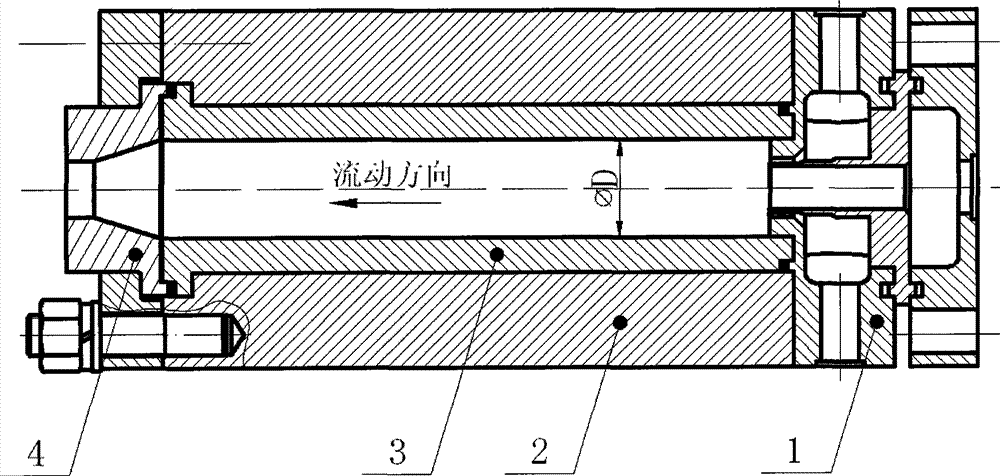

[0009] The present invention will be further described below with examples in conjunction with the accompanying drawings. The examples use the single-nozzle combustor widely used in the early stage of thrust chamber development for illustration, and the method is also suitable for multi-nozzle combustor working conditions.

[0010] The device used to implement this measurement method mainly includes: a head 1 , a body outer sleeve 2 , a body inner liner 3 , and a tail nozzle part 4 .

[0011] The whole design process is arranged as follows:

[0012] 1. Determine the number of outer sleeves 2 according to the range and number of inner diameters that need to be changed. On the one hand, it is necessary to ensure that the outer sleeve 2 occupies a certain amount of the material quality of the overall combustion chamber body, otherwise the cost savings will not be obvious; on the other hand, it must be ensured that the thickness of the inner lining 3 cannot be too thin, otherwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com