Metallurgical phase corrosive agent

A technology of corrosive agent and hydrofluoric acid, which is applied in the field of metallographic corrosive agents, can solve problems such as toxicity and health hazards of operators, and achieve the effect of clear and easy-to-distinguish grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First place 50ml of water in a plastic container, then add 10ml of hydrofluoric acid (40% by mass concentration) and 20ml of nitric acid (65% by mass concentration), and finally add 20ml of ethanol (absolute ethanol), and mix well.

[0024] After the corrosive solution is prepared, the polished titanium alloy sample is immersed in the prepared metallographic corrosive solution. When immersed, the metallographic observation surface of the sample is perpendicular to the corrosive liquid surface. The sample can be slightly shaken during etching. The etching time is 5-10 seconds. After etching, take out the alloy sample, rinse it with water repeatedly, then gently wipe the metallographic observation surface of the sample with a cotton ball dipped in alcohol, and let it dry naturally or with a hair dryer. In this way, the desired metallographic structure observation sample is obtained.

[0025] The specific steps for making metallographic photos are:

[0026] (1) Cutting s...

Embodiment 2

[0035] First place 65ml of water in a plastic container, then add 5ml of hydrofluoric acid (40% by mass concentration) and 10ml of nitric acid (65% by mass concentration), and finally add 20ml of ethanol (absolute ethanol), and mix well.

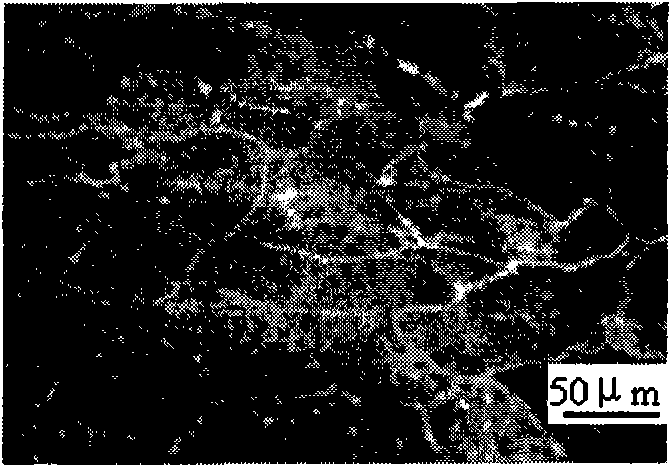

[0036] Such as image 3 As shown, it is a photo of the aging state metallographic structure of the 5523 alloy spinning pipe produced by using the etchant of the above composition, and the production method is the same as that in Example 1. This picture is the microstructure of temperature solution + aging treatment in the dual-phase region, which is a typical aging structure of β-titanium alloy, in which the dark-colored structure is the β-phase matrix, and the white structure is the α-phase precipitation.

Embodiment 3

[0038] First place 40ml of water in a plastic container, then add 10ml of hydrofluoric acid (40% by mass concentration) and 20ml of nitric acid (65% by mass concentration), and finally add 30ml of ethanol (absolute ethanol), and mix well.

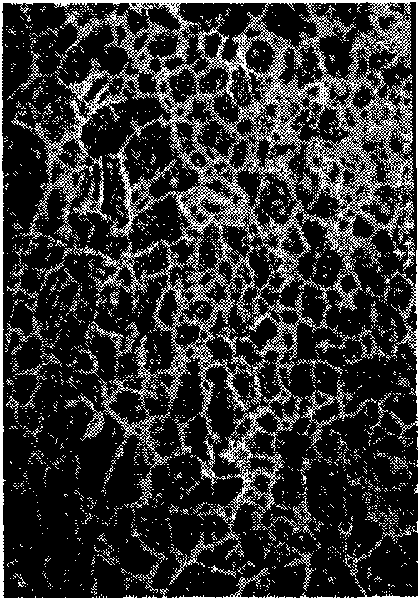

[0039] Such as Figure 4 Shown is the photo of the aging state metallographic structure of the TB8 alloy forging produced by using the etchant of the above composition, and the production method is the same as that of Example 1. This picture is the microstructure of temperature solution + aging treatment in the dual-phase region, which is a typical aging structure of β-titanium alloy, in which the dark-colored structure is the β-phase matrix, and the white structure is the α-phase precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com