Method for low-voltage thyristor reactive compensation switching of metallurgical electric furnace

A thyristor, electric furnace technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation and other directions, can solve problems such as operating overvoltage, short service life, switching, etc., to achieve fast response speed, extended service life, avoidance of effect of oversupply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

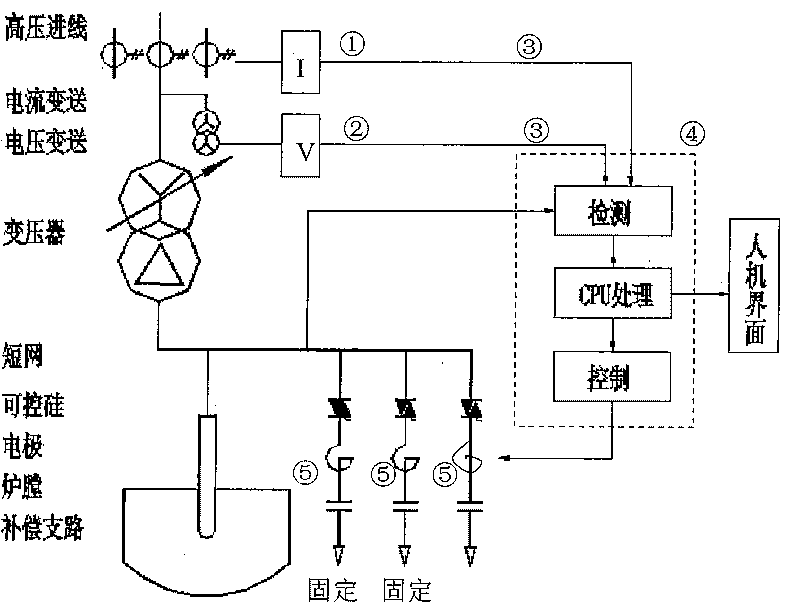

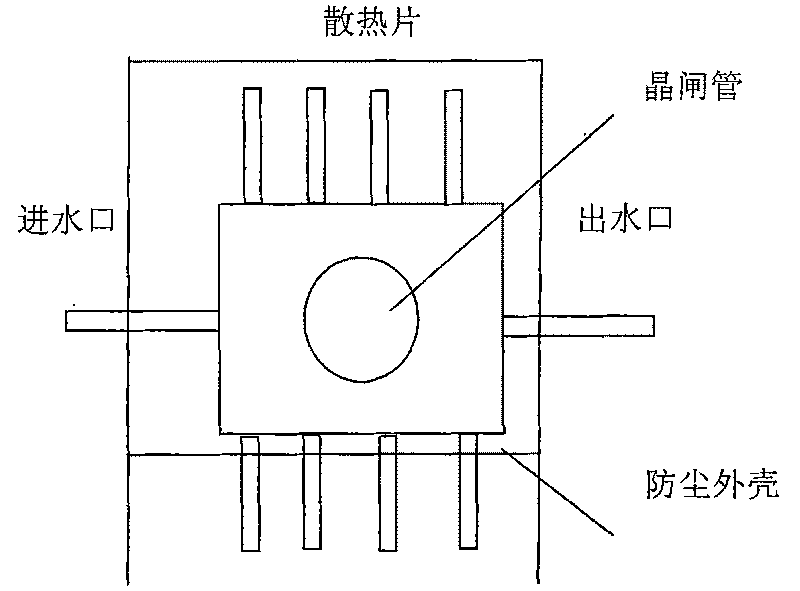

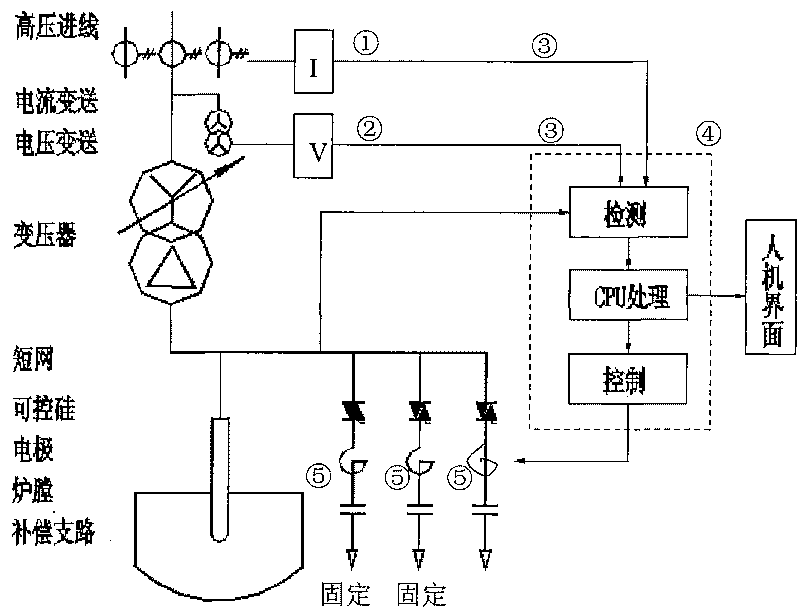

[0028] Such as Figure 1-2 Shown, the application of the present invention is as follows:

[0029] 1. On the terminal block of the switch cabinet at the high voltage side of the metallurgical electric furnace, pass the current transmitter ①, voltage transmitter ②A, B, C three-phase current and voltage signals, and transmit the secondary signal to the input terminal of the controller through the communication wire ③, The controller sends a pulse trigger signal after being processed by the CPU system.

[0030] 2. When the power of the metallurgical electric furnace is less than or equal to 0.9, the pulse signal drives the static fixed switching unit, and when the voltage crosses zero, the thyristors of each phase and group are switched on in sequence according to the time interval of 1 cycle, so that the power factor reaches 0.9.

[0031] 3. When the power of the metallurgical electric furnace reaches 0.9, the controller continues to conduct sampling and analysis, and sends a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com