Semiconductor electrode, manufacturing method thereof and solar cell having semiconductor electrode

A technology of solar cells and semiconductors, applied in the field of dye-sensitized solar cells, which can solve problems such as cracking, shedding, and poor photoelectric conversion performance of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0043] Take 3g of TiO with a particle size of 30nm 2 , 0.5g polyethylene glycol 2000 (PVA2000), 0.1mL acetylacetone, and 5mL deionized water were mixed and slowly ground, then 7mL deionized water was slowly added to it several times, after grinding for 50min, after adding 0.15mLOP emulsifier Continue grinding for 20 minutes to obtain the desired titanium dioxide slurry. The titania slurry was coated on top of the transition semiconductor layer and dried at room temperature for 24 hours. Put the dried film in a muffle furnace for sintering, raise it from room temperature to 120°C at 1°C / min, keep it for 30 minutes, then raise it to 450°C at a speed of 2°C / min, keep it for 30 minutes, anneal, and cool to The porous conductor layer can be obtained at room temperature.

[0044] The preparation method and steps of the dye layer are well known to those skilled in the art. For example, the dye layer can be formed on the porous semiconductor layer by immersing one side of the porous...

Embodiment 1

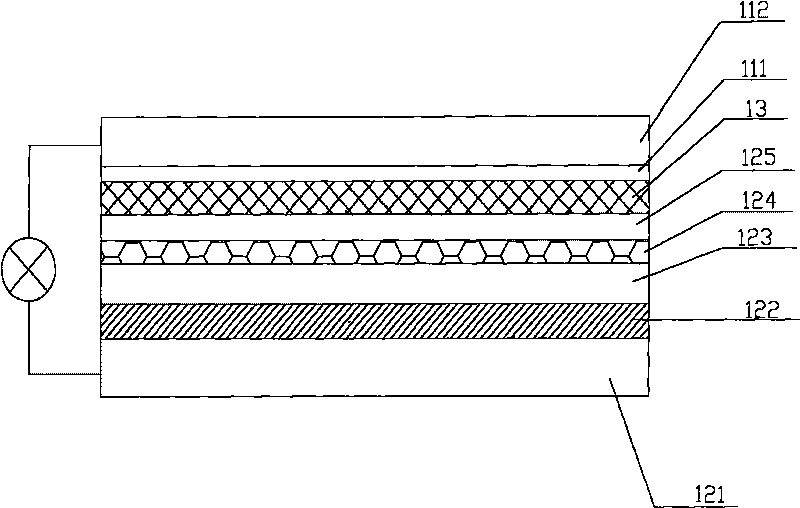

[0052] This example is used to prepare the semiconductor electrode for a dye-sensitized solar cell provided by the present invention and the dye-sensitized solar cell containing the semiconductor electrode.

[0053] (1) Preparation of dense semiconductor layer

[0054] The conductive glass (FTO conductive glass with a square resistance of 15 ohms manufactured by Qinhuangdao Yaohua Glass Co., Ltd., with a thickness of 4 mm) coated with a fluorine-doped tin dioxide layer with a size of 3 × 1.5 cm is used as a pre-plating workpiece. With TiO2 as the evaporation source, the electron beam current is 180mA, and the vacuum degree is 1×10 -3 A dense semiconductor layer A1 with a thickness of 0.1 micron was formed on one side of the conductive bottom layer by vacuum evaporation for 5 minutes under the condition of Pa. The porosity of the dense semiconductor layer is 0.1% as detected by an automatic mercury porosimeter (Mike Instruments Inc., Auto Pore IV9500, USA).

[0055] (2) Prepa...

Embodiment 2

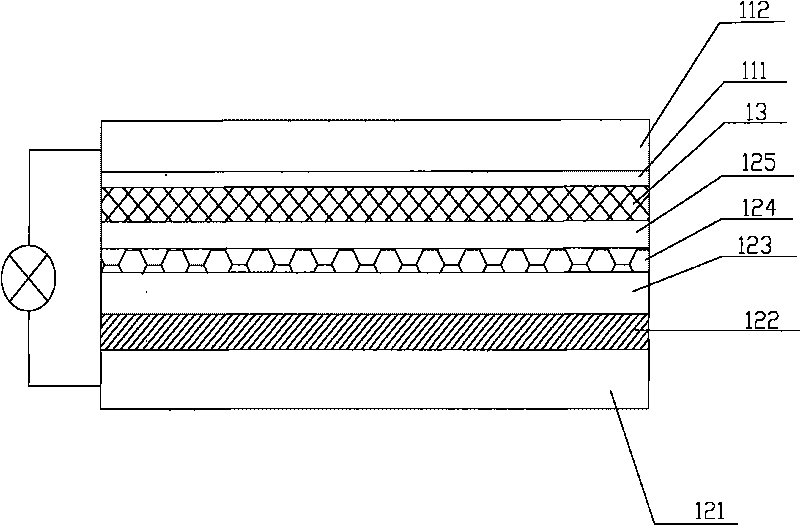

[0067] This example is used to prepare the semiconductor electrode for a dye-sensitized solar cell provided by the present invention and the dye-sensitized solar cell containing the semiconductor electrode.

[0068] (1) Preparation of dense semiconductor layer

[0069] The conductive glass (FTO conductive glass with a square resistance of 15 ohms manufactured by Qinhuangdao Yaohua Glass Co., Ltd., with a thickness of 4 mm) coated with a fluorine-doped tin dioxide layer with a size of 3 × 1.5 cm is used as a pre-plating workpiece. with TiO 2 As the evaporation source, the current of the electron beam is 360mA, and the degree of vacuum is 8×10 -3 Vacuum evaporation under the condition of Pa for 30 minutes forms a dense semiconductor layer A2 with a thickness of 10 microns on one side of the conductive bottom layer. The porosity of the dense semiconductor layer is 2.0% as detected by an automatic mercury porosimeter (Mike Instruments Inc., Auto Pore IV9500, USA).

[0070] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com