Borate microcrystalline glass and method for preparing same

A technology of glass-ceramic and borate, which is applied in the fields of optoelectronics and lighting engineering, can solve the problems of high production cost of light-emitting devices, unstable phosphor emission, and easy aging, and achieve good photoluminescence performance and good chemical stability and thermal stability, good light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 1.57g of sodium carbonate, 3.35g of yttrium oxide, 5.51g of boric acid, 2.52g of aluminum oxide and 0.08g of cerium oxide, and obtain a uniform powder by ball milling or mortar grinding. Put the ground raw material into an alumina crucible, put it into a high-temperature furnace, and keep it at a high temperature of 1630°C for 30 minutes to melt it. After melting, the material is poured into a stainless steel plate, quenched and formed into glass. Place the shaped glass in N 2 with H 2 15Na 2 O-15Y 2 o 3 -25Al 2 o 3 -45B 2 o 3 -0.5CeO 2 (The coefficient in the chemical formula is the mole fraction of the component, the same below) borate glass-ceramics.

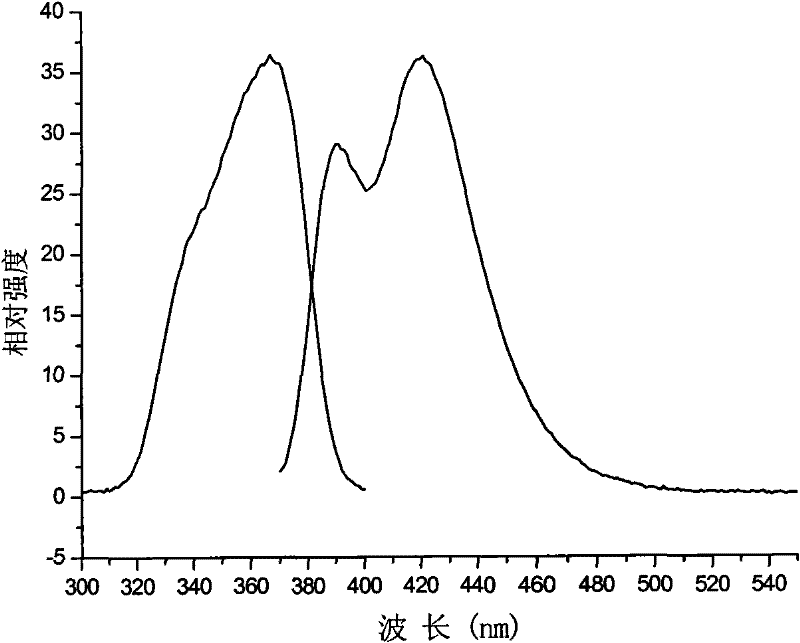

[0034] The borate glass-ceramics obtained in this embodiment can be excited by violet light in the wavelength range of 320-380 nm. Under the excitation of 366nm purple light, the luminescent color is blue and the brightness is high. like figure 1 As shown, the excitation wavelength range is 320-380nm,...

Embodiment 2

[0036] Weigh 5.17g of sodium carbonate, 9.81g of yttrium oxalate, 13.72g of boric acid, 12.7g of aluminum oxalate and 0.15g of cerium oxide, and obtain a uniform powder by ball milling or mortar grinding. Put the ground raw material into an alumina crucible, put it into a high-temperature furnace, and keep it at a high temperature of 1580°C for 30 minutes to melt it. After melting, the material is poured into a stainless steel plate, quenched and formed into glass. Place the formed glass in H 2 In a reducing atmosphere, heat treatment at 650°C for 6 hours to obtain 22Na 2 O-10Y 2 o 3 -18Al2 o 3 -50B 2 o 3 -0.4CeO 2 Luminous glass-ceramic.

Embodiment 3

[0038] Weigh 2.87g of sodium carbonate, 2.76g of yttrium oxide, 6.04g of boric acid, 2.07g of aluminum oxide and 0.07g of cerium oxide, and obtain a uniform powder by ball milling or mortar grinding. Put the ground raw material into an alumina crucible, put it into a high-temperature furnace, and keep it at a high temperature of 1650°C for 30 minutes to melt it. After melting, the material is poured into a stainless steel plate, quenched and formed into glass. Place the shaped glass in N 2 with H 2 25Na 2 O-11.25Y 2 o 3 -18.75Al 2 o 3 -45B 2 o 3 -0.5CeO 2 Luminous glass-ceramic.

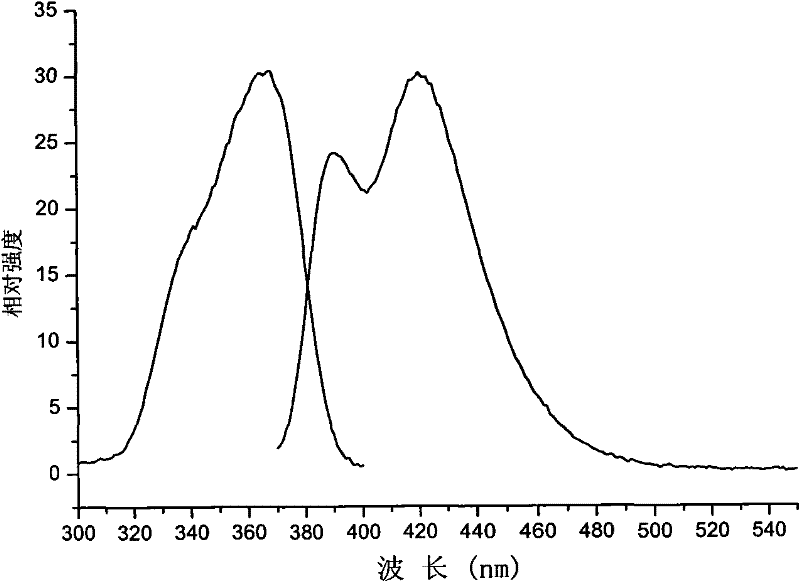

[0039] The glass-ceramics obtained in this embodiment can be excited by violet light in the wavelength range of 320-380 nm. Under the excitation of 366nm purple light, the luminescent color is blue and the brightness is high. like figure 2 As shown, the excitation wavelength range is 320-380nm, the emission wavelength range is 400-460nm, the main emission peak is located at 420nm, and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com