Method for treating or recycling waste water with high salt content and applications

A technology for wastewater treatment and high salt content, which is applied in biological water/sewage treatment, flotation water/sewage treatment, adsorbed water/sewage treatment, etc. and other problems, to achieve the effect of strong impact resistance, lower processing and operating costs, and less sludge production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

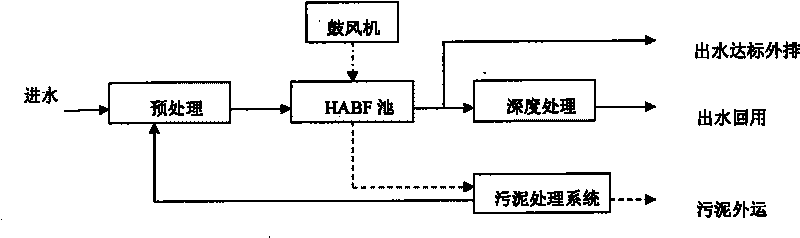

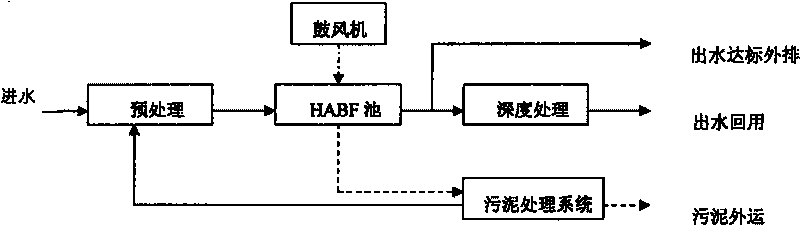

Image

Examples

Embodiment 1

[0021] A large metallurgical enterprise in the north discharges 500m of saline sewage per day 3 / h, the salty sewage is the pre-membrane concentrated water of the first-stage reverse osmosis membrane in a second-stage reverse osmosis membrane device in the enterprise. The wastewater before concentration is mainly the comprehensive wastewater after sedimentation and filtration in the factory area. -4 times. At present, the company intends to treat the concentrated solution to reduce the amount of COD discharged by the company, meet the national emission reduction index requirements for the company, and realize the recycling of wastewater. Using "HABF+O 3 / BAC+ultrafiltration+reverse osmosis” is the main process to conduct a small test experiment on site. The experimental water flow rate is 40L / h, the effective volume of the HABF reaction tank is 240L, and it is divided into 5 stages of series operation. The hydraulic retention time is 6h, and the carrier is filled. The amount i...

Embodiment 2

[0023] Using HABF as the main process, a small test experiment was carried out in an oil field in North China. The experimental water flow rate was 4L / h, the effective volume of the HABF reaction tank was 16L, the hydraulic retention time was 4h, and the carrier loading was 60% (high-efficiency carrier accumulation The volume is 9.6L), and the inoculated microorganism is engineering bacteria (BCP35M). The influent water of the experiment is the effluent water after oil separation and air flotation in the oil production plant, with a salt content of 5000-10000mg / L. 5 , TOC, petroleum, SS and sulfide average concentration are 124.1mg / L, 62.5mg / L, 37.7mg / L, 19.7mg / L, 130.0mg / L and 19.7mg / L, effluent COD, BOD 5 , TOC, petroleum, SS and hydrogen sulfide average concentrations are 17.9mg / L, 5.9mg / L, 9.7mg / L, 1.9mg / L, 10.9mg / L and 0.002mg / L respectively, COD, BOD 5 , TOC, petroleum, SS and hydrogen sulfide average removal rate reached 85.6%, 90.6%, 74.4%, 90.5%, 91.6% and 100%.

Embodiment 3

[0025] The sewage treatment plant of a petroleum refining and chemical enterprise in the north adopts the "old three" process of oil separation, flotation, and blast aeration, without water quality and quantity adjustment measures, and sulfur-containing sewage is stripped to purify water, alkali residue sewage, and oily sewage Combined treatment is adopted in the treatment site, so it is often impacted by the changes of excessive quality and excess sewage. At the same time, with the expansion of oil refining scale and the continuous improvement of production equipment reconstruction and expansion, the total amount of sewage discharge is increasing day by day, and with the continuous increase of crude oil processing volume and processing depth, the pollutant load in sewage discharged from equipment continues to increase, resulting in existing It is difficult for sewage treatment plants to meet the needs of production and the requirements of discharge standards. According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com