Special compound additive for polyethylene film with high tranparency and low density

A technology of low-density polyethylene and compounding additives, applied in the field of special compounding additives, can solve the hidden dangers of film physiological safety, film products are easy to stick to each other, fish eyes, and high turbidity, and achieve good physiological safety, high Safety and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Put each auxiliary agent of the present invention into a cantilever double-helix conical mixer according to the following weight ratio for premixing and coarse dispersion:

[0043] High-efficiency opening agent: 28

[0044] Silicone glidants: 12

[0045] Silicone reactive crosslinker: 5

[0046] Silicone antioxidant: 8

[0047] High pressure polyethylene carrier resin: 47

[0048] The operating speed of the cantilever double-helix conical mixer is 40-50 revolutions per minute, and the mixer is stirred for 60 minutes.

[0049] 2. Put the pre-mixed raw materials into a horizontal ball mill with a rotation speed of 45-50 revolutions per minute and a temperature of 80°C to preheat the raw materials for chemical bonding and refinement dispersion.

[0050]3. Put the above-mentioned finely dispersed raw materials into a twin-screw granulator, extrude and granulate at a flow rate of 200kg / hour at a temperature of 140°C-170°C to obtain the compound additive granules of th...

Embodiment 2

[0052] The weight ratio of each component is as follows:

[0053] High-efficiency opening agent: 30

[0054] Silicone glidants: 13

[0055] Silicone reactive crosslinker: 6

[0056] Silicone antioxidant: 8

[0057] High pressure polyethylene carrier resin: 43

[0058] Operate the above-mentioned mixture according to the process conditions of Example 1, and finally extrude and granulate to obtain the additive granules of the present invention.

Embodiment 3

[0060] Put each component of the present invention into the cantilever double-helix conical mixer according to the following weight ratio for premixing and coarse dispersion:

[0061] High-efficiency opening agent: 20

[0062] Silicone glidants: 6

[0063] Silicone reactive crosslinker: 4

[0064] Silicone antioxidant: 8

[0065] High pressure polyethylene carrier resin: 62

[0066] Other operation production technology is with embodiment 1.

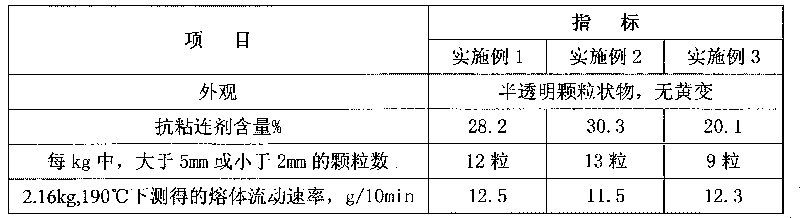

[0067] The relevant physical indicators of the three compound additives are shown in Table 1.

[0068] Table 1

[0069]

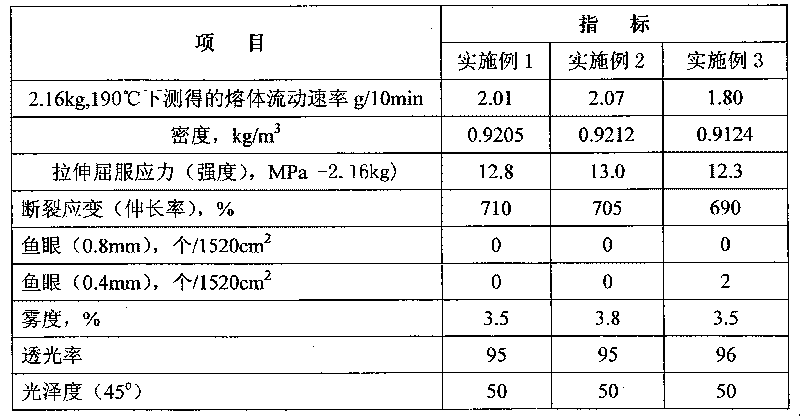

[0070] Add the composite additives of the above three examples into the low-density polyethylene resin respectively at 2.5‰ (weight), and test the obtained high-pressure polyethylene product data as shown in Table 2.

[0071] Table 2

[0072]

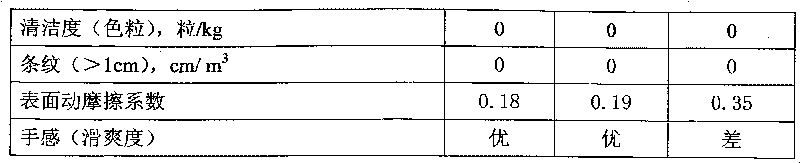

[0073]

[0074] The film was left for half a month and no oily, hoarfrost and other phenomena were found. There is no difference in smoothness between the film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com