Method for forming pattern for transparent conductive layer

A technology of transparent conductive layer and transparent conductive film, applied in the direction of transparent dielectric, conductive layer on insulating carrier, circuit, etc., can solve problems such as difficult to remove accurately, difficulty, pattern short circuit, etc., and achieve excellent manufacturing efficiency and high manufacturing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] Hereinafter, the present invention will be described more specifically by citing examples in the production of a transparent conductive layer film for a touch panel when the transparent conductive substance is a nanowire, but the present invention is not limited to these examples.

[0124](a) (Synthesis of silver nanowires)

[0125] Silver nanowires are described in Y.Sun, B.Gates, B.Mayers, and Y.Xia, "Crystalline silver nanowires by soft solution processing", Nano letters, (2002), 2(2) 165-168 Nanowires synthesized by dissolving silver sulfate in ethylene glycol and reducing it in the presence of polyvinylpyrrolidone (PVP) as a mold followed by the method of using polyalcohol as a reducing agent. That is, in the present invention, nanowires synthesized by a modified polyol method as described in Cambrios Technologies Corporation US Provisional Application No. 60 / 815627 are used.

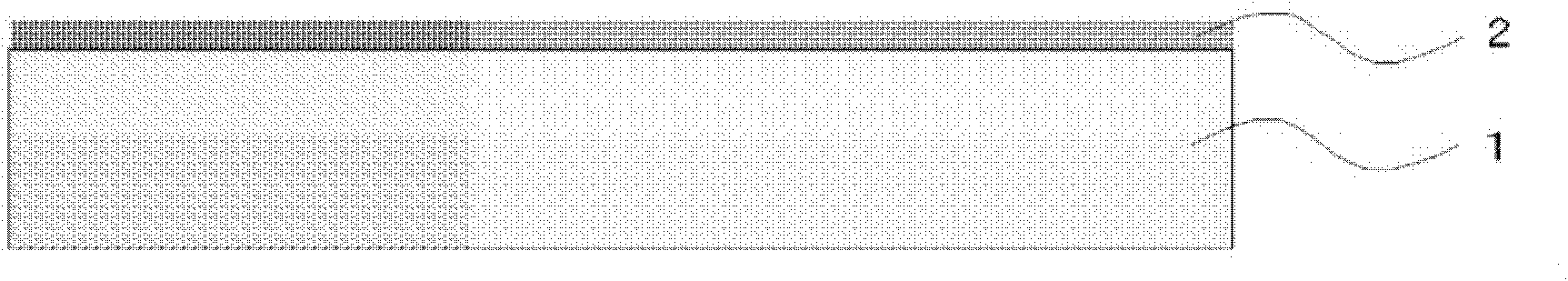

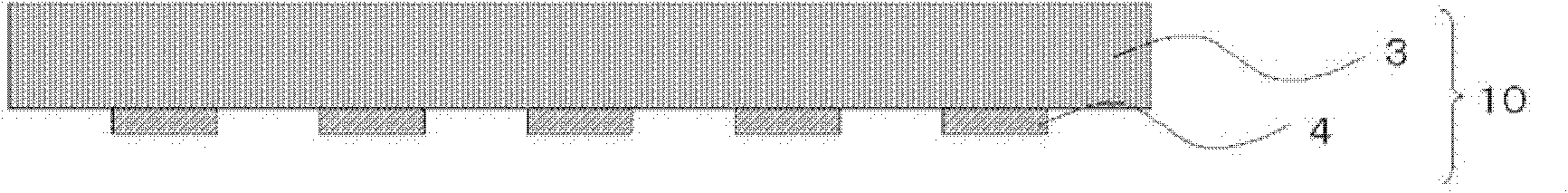

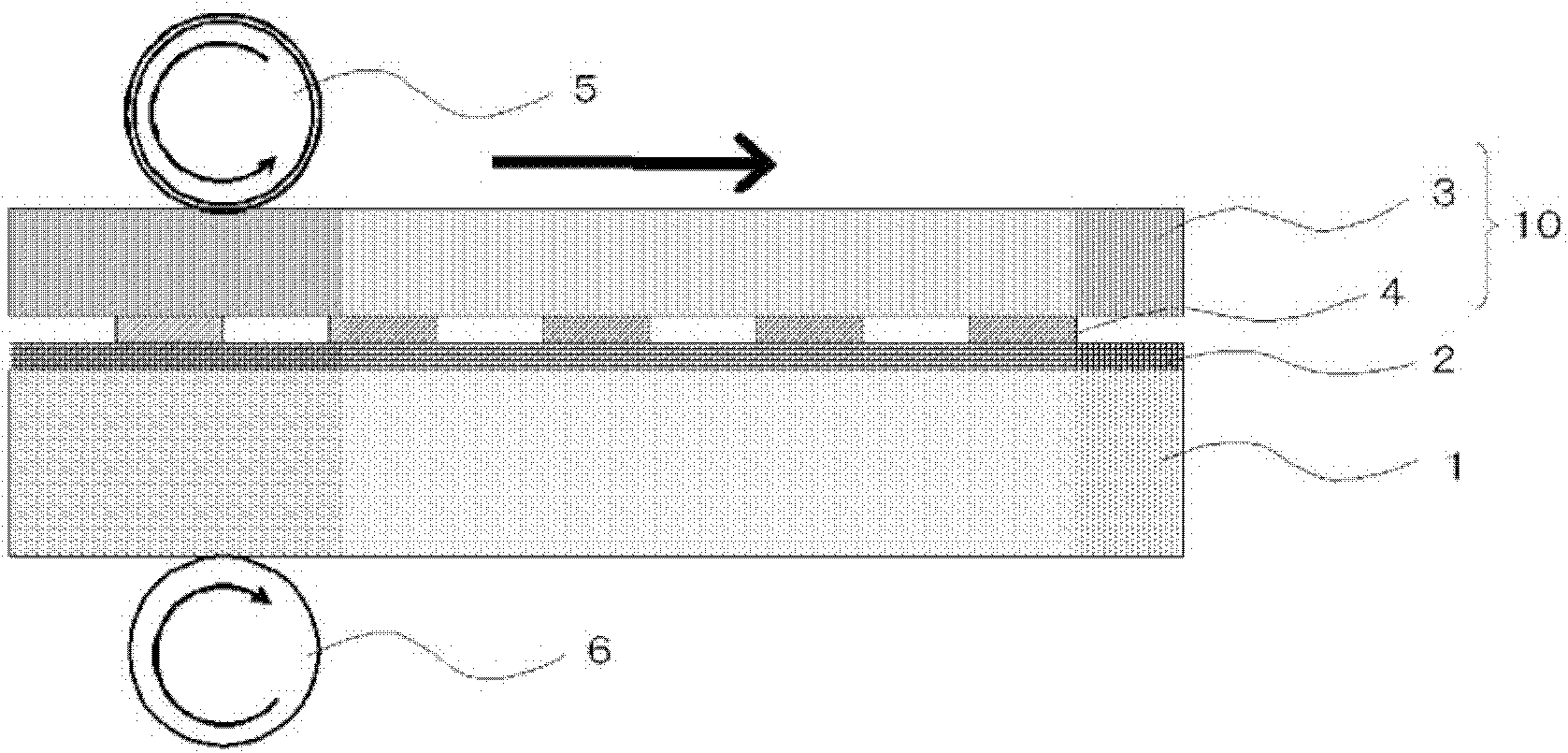

[0126] (b) (Formation of transparent conductive layer)

[0127] As metal nanowires to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com