Spiral-line multi-pole lug lithium ion battery and method for manufacturing same

A lithium-ion battery, multi-pole technology, applied in secondary batteries, battery pack components, final product manufacturing, etc., can solve problems such as unfavorable pole piece trimming burrs, unfavorable high-current charging and discharging, and unfavorable resistance welding, etc. Achieve the effect of reducing internal short-circuit and low-voltage defective products, uniform charge and discharge current distribution, and solving unsuitable laminations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

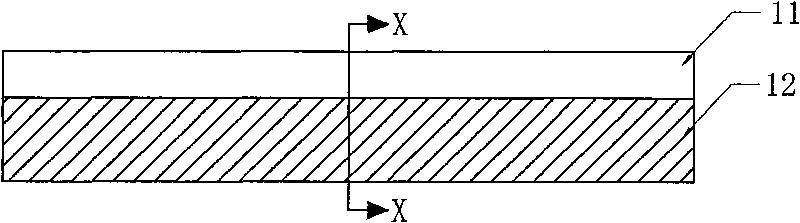

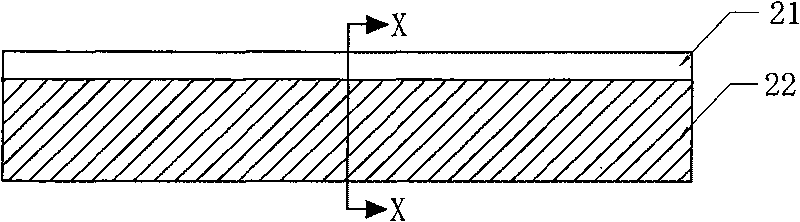

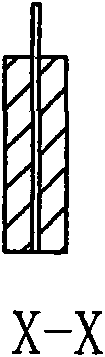

[0035] as attached figure 1 , attached figure 2 , attached image 3 As shown, in the present invention, the active material, the conductive agent and the binder are fully mixed in a certain proportion to make a mixed paste, which is applied to the current collector by roller coating, scraping or spraying, and coated on the front side of the positive electrode sheet. Apply paste 12, reserve a blank position 11 on the front of one edge in the longitudinal direction of the positive electrode sheet, apply paste 22 on the back of the positive electrode sheet, and reserve a blank position on the back of one edge in the longitudinal direction of the positive electrode sheet twenty one.

[0036] as attached Figure 4 , attached Figure 5 , attached Figure 6 As shown, the negative electrode sheet of the present invention leaves a blank position 41 on the front of one edge in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com