Open low-temperature heat source refrigerating system

A low-temperature heat source and refrigeration system technology, applied in the field of air conditioning and refrigeration engineering, can solve the problems of low coefficient of performance, can not operate normally, easy to destroy the vacuum environment, etc. The effect of mass driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

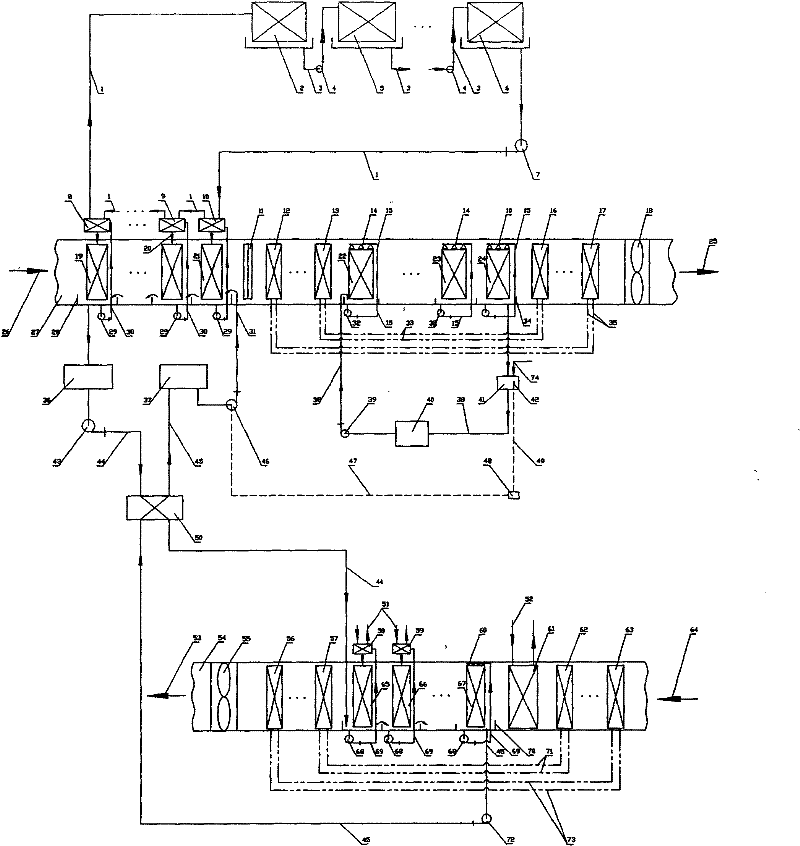

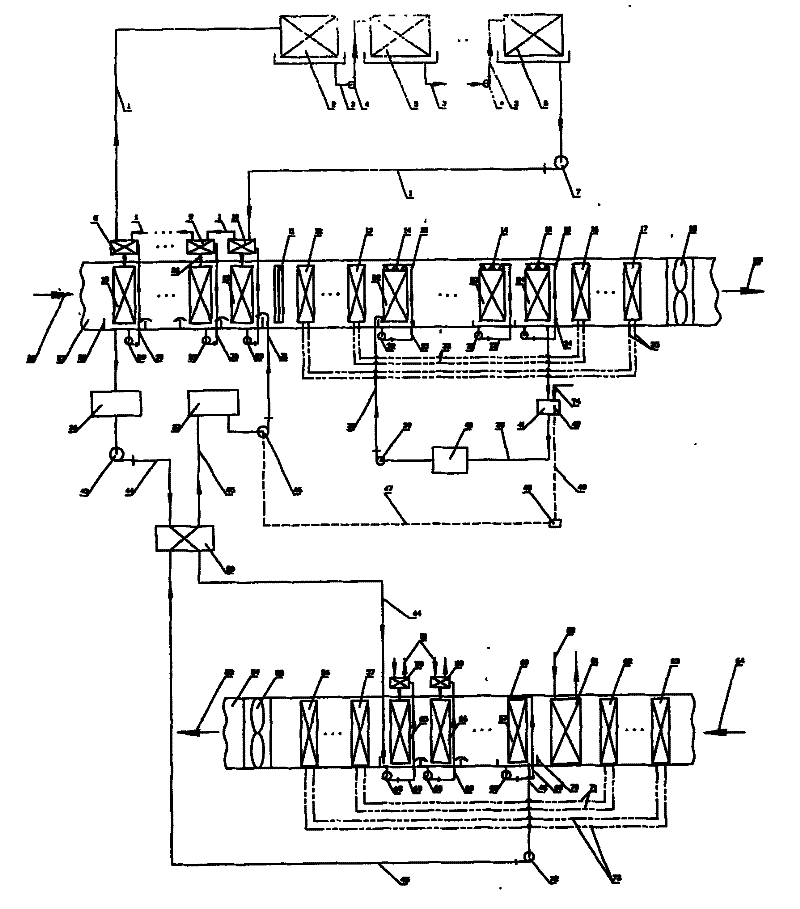

Image

Examples

Embodiment 1

[0032]The air duct 27 in the functional area of the main body, the liquid baffle plate 11 and the fan 18 in the functional area of the main body in this embodiment constitute an open air flow subsystem. The subsystem uses the power provided by the fan 18 to make the air flow through the N in the air duct sequentially. Level solution processing subsystem (1≤N≤20), Q level heat pipe cooling recovery subsystem (1≤Q≤20) and N1 level water circulation treatment subsystem (1≤N1≤20); working solution tank 28, working solution Circulation pump 29, working solution circulation pipe 30, working solution heat exchanger 8, 9 or 10, working solution liquid distribution pipe 20, solution processing liquid distribution device 19, 21 constitute N-level solution processing subsystem (1≤N≤20) In this subsystem, the working solution circulation pump 29 sends the working solution in the working solution tank 28 through the working solution circulation pipe 30 into the working solution heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com