Nano-composite organic spin valve

A nanocomposite, spin valve technology, applied in the field of spin electronics, can solve the problems of strict requirements for spin valve preparation and no room temperature magnetoresistance effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

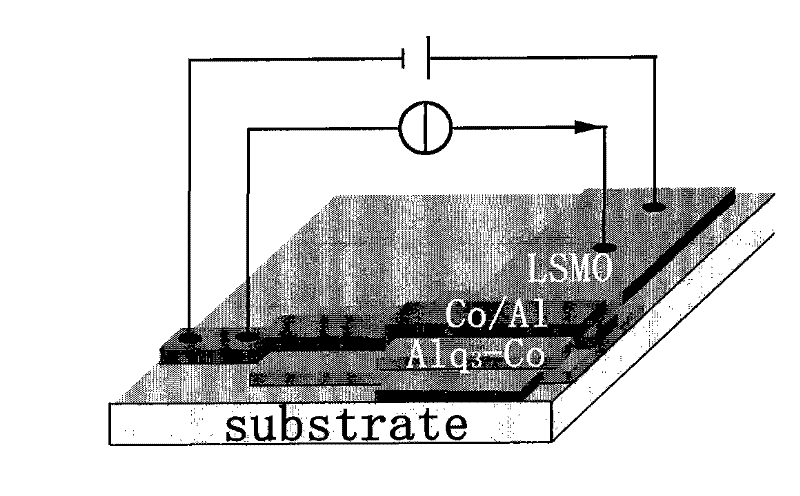

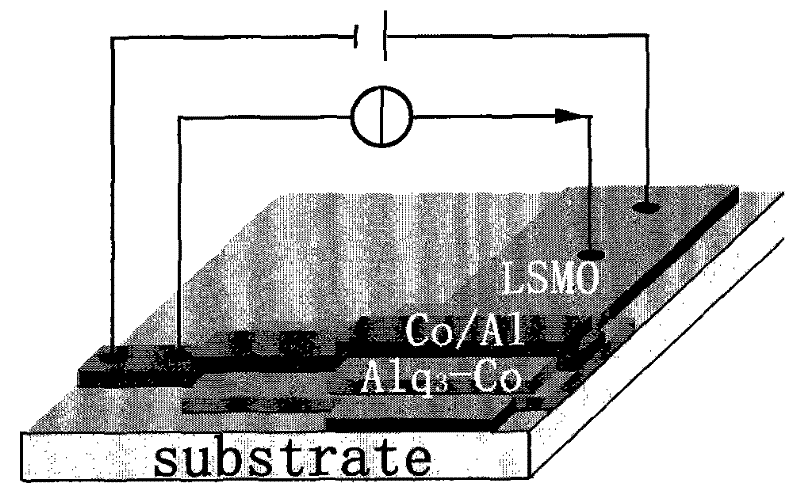

[0018] Such as figure 1 A nanocomposite organic spin valve is shown. The spin valve is composed of a sandwich structure. The top electrode is a transition metal cobalt film with an aluminum film as a protective layer, the bottom electrode is a lanthanum strontium manganese oxide film, and the middle transport layer It is a nanocomposite of transition metal cobalt and small organic molecule octahydroxyquinoline aluminum.

[0019] The preparation method of the above-mentioned nanocomposite organic spin valve is as follows:

[0020] 1) Prepare a lanthanum strontium manganese oxide film with a thickness of 100nm on a strontium titanate substrate by laser pulse deposition method, as the bottom electrode of the spin valve;

[0021] 2) Corrode the bottom electrode of lanthanum strontium manganese oxide to a surface area of 2×10mm 2 Put the long strips into the multi-source high-vacuum thermal evaporation chamber, and evacuate the multi-source high-vacuum thermal evaporation chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com