Bioreactor

A bioreactor and assembly technology, applied in biochemical instruments, biochemical equipment and methods, tissue cell/virus culture devices, etc., can solve problems such as uneven distribution of cells, dead shells, insufficient oxygen supply, etc., to achieve The effect of improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

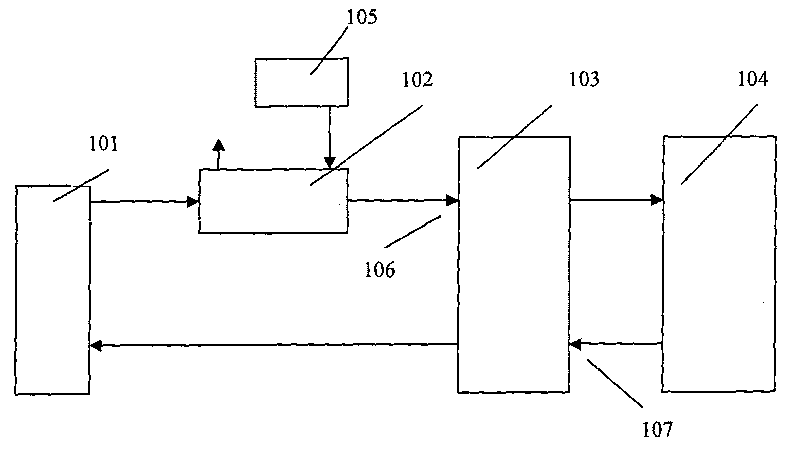

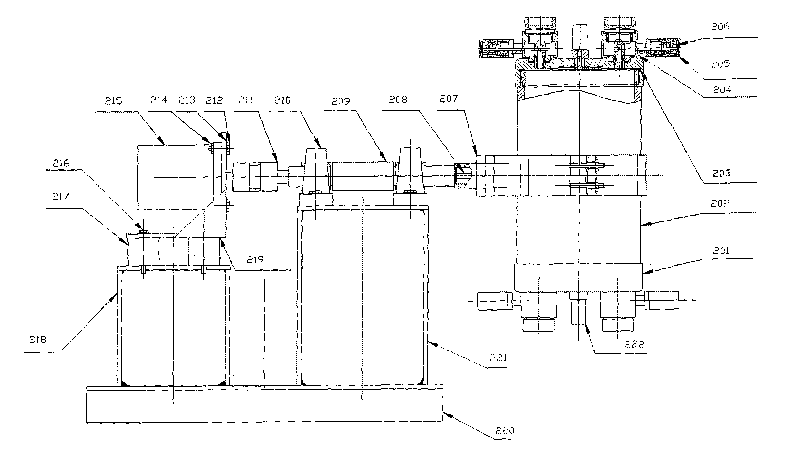

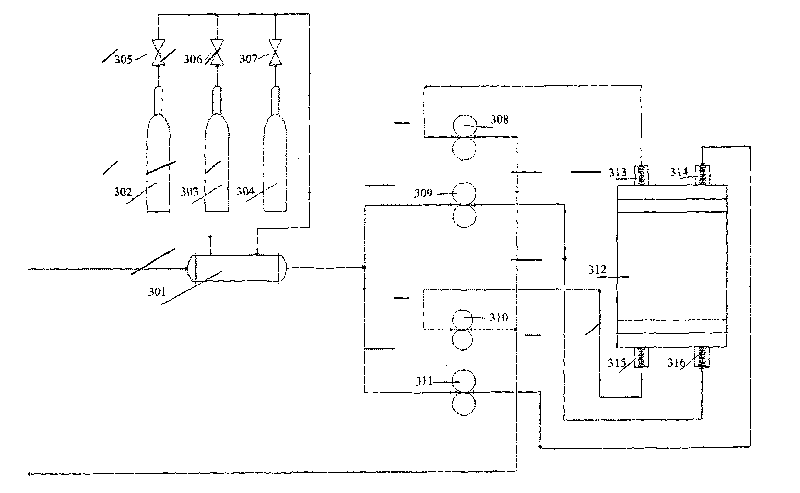

[0047] The invention consists of a reciprocating rotating cell culture tank assembly module, a gas dispersion control assembly module and a liquid flow direction control assembly module connected in series through a cell culture liquid circulation pipeline. The connections between them are as figure 1 shown. The pipeline from the peripheral equipment of the bioreactor of the present invention is connected to the first port of the tube lumen of the gas dispersion control assembly module (102); the second port of the tube lumen of the gas dispersion control assembly module (102) is connected to the liquid flow direction control The first input port (106) of the assembly module; the output port of the liquid flow control assembly module (103) is connected to the input port of the reciprocating and rotating cell culture tank assembly module (104);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com