Method for simultaneously removing sulfur dioxide and nitrogen oxide in exhaust gas by twin tower tandem catalysis-biomembrane packing tower system

A technology for sulfur dioxide and nitrogen oxides, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of insufficient purification efficiency of NOx and the limitation of comprehensive utilization channels, and achieve convenient and comprehensive utilization and expansion of comprehensive utilization The effect of the pathway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

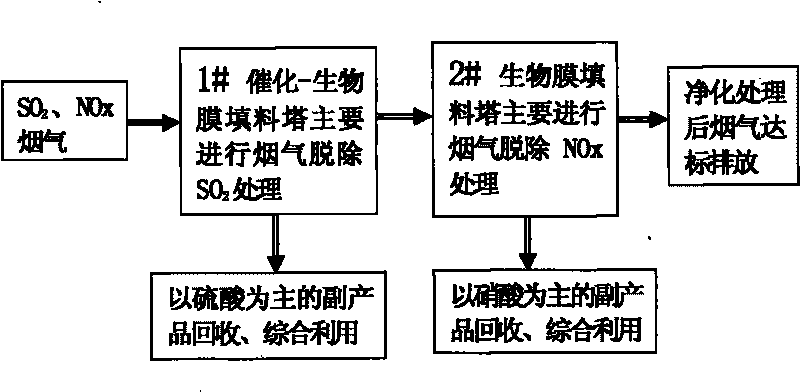

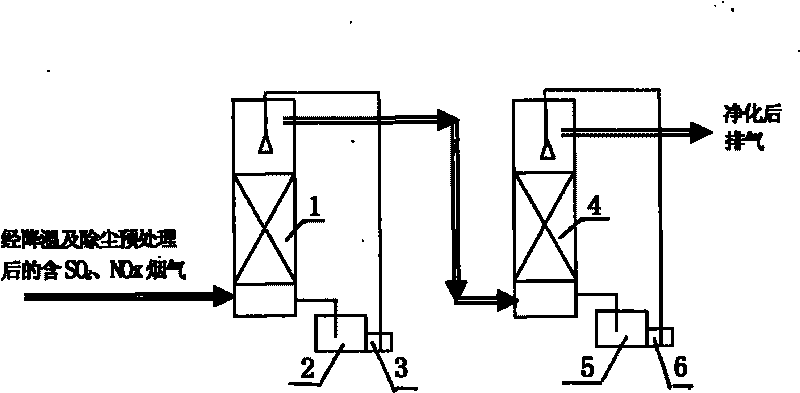

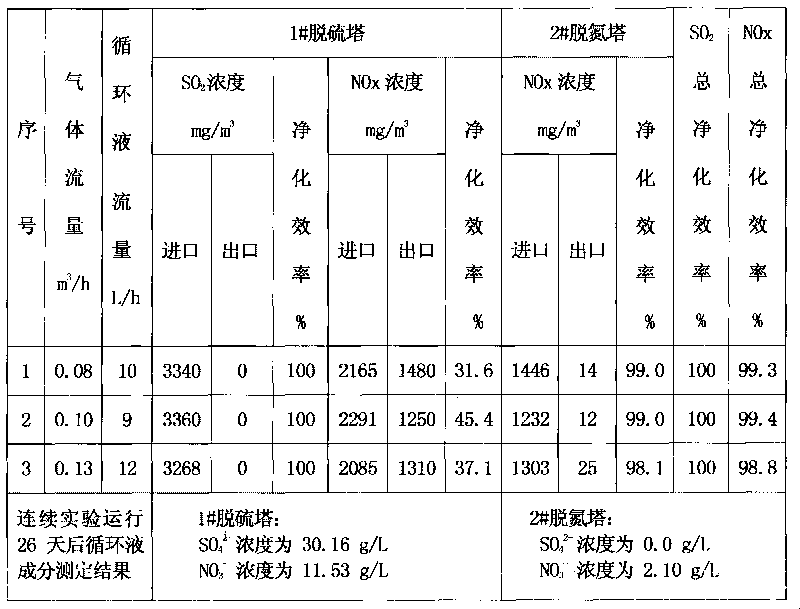

[0029] Examples 1 to 3: Using a double tower series catalytic-biofilm packed tower system to simultaneously remove SO from flue gas 2 And NOx and by-product sulfuric acid and nitric acid. 2 And NOx industrial waste gas for purification treatment experiments. The experimental device is composed of two biofilm packing tower systems with the same structure in series. The process is as follows figure 1 Shown.

[0030] The pH buffer used to adjust the pH of the circulating spray liquid is sodium bicarbonate (NaHCO 3 ) Prepared with NaHCO 3 10% buffer solution.

[0031] The special metal ion combination catalyst used is Fe-containing 2+ , Mn 2+ , Zn 2+ , Al 3+ The catalyst prepared by four kinds of metal ion sulfate, when added to the circulating spray liquid, Fe in the circulating spray liquid 2+ , Mn 2+ , Zn 2+ , Al 3+ The concentrations of the four metal ions are 0.5%, 0.2%, 0.5%, 1.0%, and the total concentration of metal ions is 2.2%.

[0032] The invention adopts a proprietary exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com