Method and device for continuously heating and sterilizing solid materials by tubular microwaves

A technology of heat sterilization and microwave heating, which is applied in the direction of heating, water supply equipment, sanitary equipment for toilets, etc., and can solve related problems such as complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

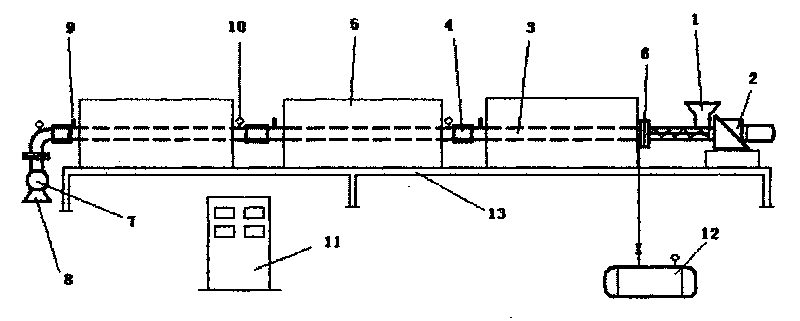

Image

Examples

Embodiment 1

[0020] The tubular microwave continuous heating and sterilizing solid material device is composed of a pressurized solid material conveying system, a microwave heating system and an automatic control system. Among them, the pressurized solid material conveying system is composed of a feed inlet (1), a screw pump (2), a feed pipe (3), a rotary sealing valve (7), and a discharge port (8); the heating system is mainly composed of an array of graded The heating microwave oven (5) is composed of a steam generator (12); the steam generator (12) is only used as an auxiliary equipment for the sterilization and heating system inside the device when the whole device is started, and the tubular microwave continuous heating and sterilizing solid material device starts And after normal operation, the steam generator should be closed in time; the control system is mainly composed of a pressure sensor (10), a temperature sensor (9) and a related control device (11) installed between the micro...

Embodiment 2

[0026]In the production process of solid-state fermentation to produce red yeast rice, protease, pectinase, cellulase, citric acid, ethanol, lactic acid, gibberellin, vitamins, soy sauce, vinegar, liquor, protein feed, b.t. preparations, edible fungi, etc. , the medium for solid-state fermentation needs to be sterilized. With the present invention, the solid material to be sterilized is pushed into the feed pipe (3) from the feed port (1) via the screw pump (2). The propelling force of the material is provided by the screw pump. Under the push of the screw pump, the solid material enters the delivery pipe from the feed port and is pushed to the discharge port. Rotary seal valve connection can control the continuous output of materials while ensuring sufficient steam pressure and sterilization temperature in the delivery pipe. When the solid material travels in the feeding pipe, it is heated and sterilized by the microwave heating chamber (5). The sterilization temperature and...

Embodiment 3

[0028] In the process of food processing, the present invention is used to continuously heat and sterilize dried fruits, candied fruit, pickles, various seasoning powders, etc.; the sterilization temperature is selected in the range of 120°C-140°C depending on the nature of the material and the requirements of the sterilization process. The working pressure of pressurized steam is generally selected between 0.2063Mpa-0.3653Mpa, and the time is 0.1-20 minutes. The corresponding products after sterilization are more hygienic and safer to eat, and the shelf life and shelf life of the products are more guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com