Oridonin-loaded micelle preparation and preparation method thereof

A technology of oridonin A and micelles is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, and medical preparations without active ingredients, which can solve the problems of no oridonin A pharmaceutical preparations and the like, and achieve The drug loading is easy to control, convenient for drug efficacy evaluation and standard formulation, and the effect of no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

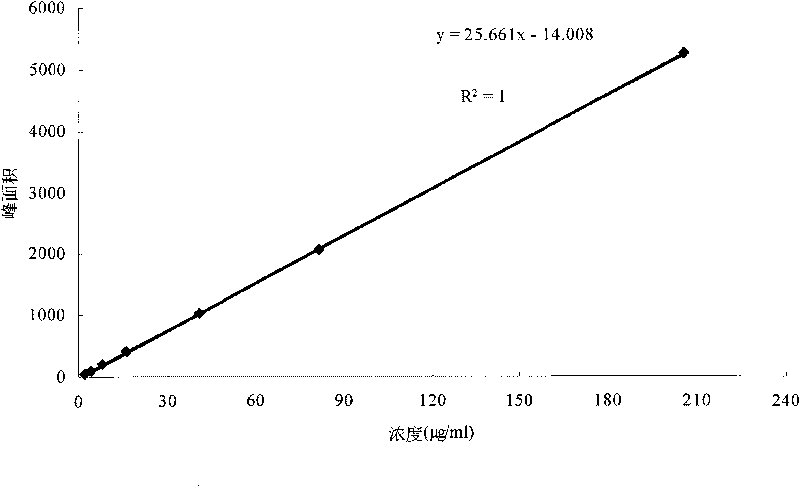

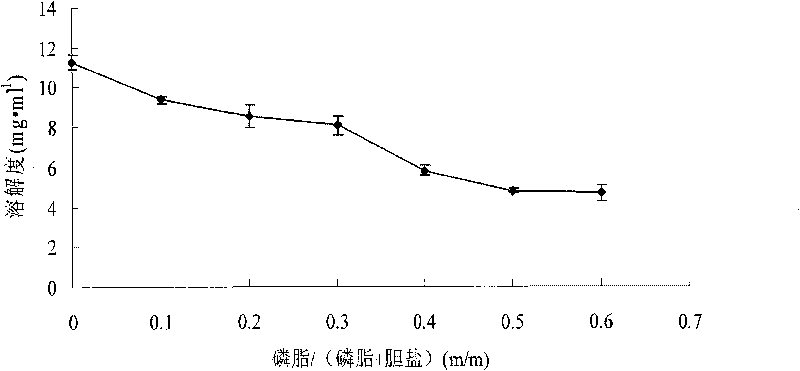

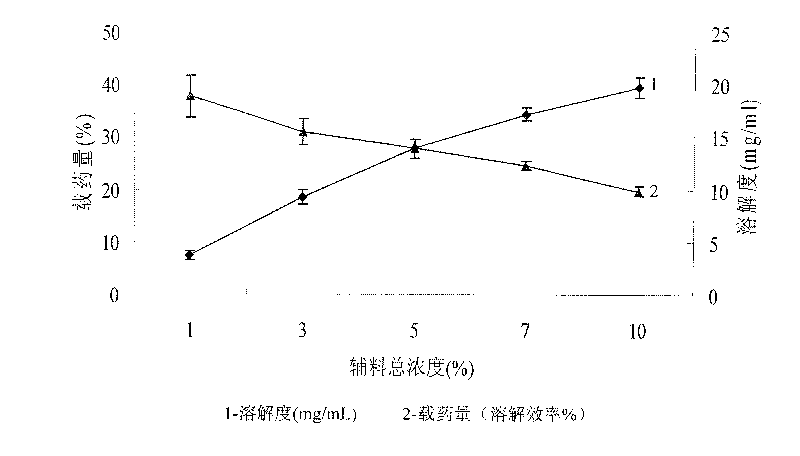

Method used

Image

Examples

Embodiment 1

[0037] Take 20 mg of Rubescensine A, 40 mg of phospholipids with a molecular weight distribution of 700-800, and 40 mg of bile salts, add 20 mL of absolute ethanol at 20°C and ultrasonically dissolve until clarified. Complete, after the material is constant weight, add 10 mg of 10 ℃ deionized water and carry out rotary hydration, transfer the hydrated material to a centrifuge tube, and centrifuge at 13000rpm for 5min, then discard the precipitate, take the supernatant, and obtain The supernatant was filtered through a 0.22 μm microporous membrane to obtain the oridonin A micelle preparation with a drug loading of 20%. In the present embodiment, the phospholipid is soybean phospholipid, and the bile salt is sodium deoxycholate. Of course, the phospholipid can also be egg yolk lecithin. The advantage of selecting soybean lecithin is that the purity of soybean lecithin is higher, and the bile salt can also be cholic acid Sodium, the advantage of using sodium deoxycholate is that ...

Embodiment 2

[0042] Take 10 mg of Rubescensin A, 70 mg of egg yolk lecithin with a molecular weight distribution of 700-800, and 20 mg of sodium cholate, add 30 mL of methanol at 60°C and ultrasonically dissolve until clarified, then evaporate under reduced pressure in a water bath at 35°C, and wait for the organic solvent After complete evaporation and constant weight of the material, add 50 mg of 0.05 mol / kg NaCl solution at 60°C and rotate for hydration, transfer the hydrated material to a centrifuge tube, and centrifuge at 8000 rpm for 5 min, then discard the precipitate , take the supernatant, and filter through a 0.22 μm microporous membrane to obtain the oridonin A micelle preparation, with a drug loading of 10%.

Embodiment 3

[0044] Take 10 mg of Rubescensin A, 10 mg of dipalmitate phosphatidylcholine with an average molecular weight of 734, and 80 mg of sodium deoxycholate, and add 40 mL of a mixture of methanol and chloroform at 40°C (the weight ratio of methanol to chloroform is 1:1) and ultrasonically dissolved until clarified, and then the material was subjected to reduced-pressure rotary evaporation in a water bath at 40°C. After the material was constant weight, 20 mg of pH 6.0 phosphate buffer solution at a temperature of 40°C was added and rotated for hydration. After hydration, the material was transferred into a centrifuge tube and centrifuged at 10,000rpm for 5min, discard the precipitate, and get the supernatant, which was filtered through a 0.22 μm microporous membrane, and the filtrate was freeze-dried to obtain the oridonin A micelle preparation. Freeze-dried powder with a drug loading of 10%. In this embodiment, the dipalmitate phosphatidylcholine can also be replaced by synthetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com