Nano superhydrophobic surface used for airplane antifreezing and deicing and preparation method thereof

A super-hydrophobic surface and nano-technology, applied in aircraft parts, deicing devices, optomechanical equipment, etc., can solve problems such as huge power consumption, difficult implementation, and complex design, so as to reduce the amount of condensation and reduce icing degree, the effect of reducing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

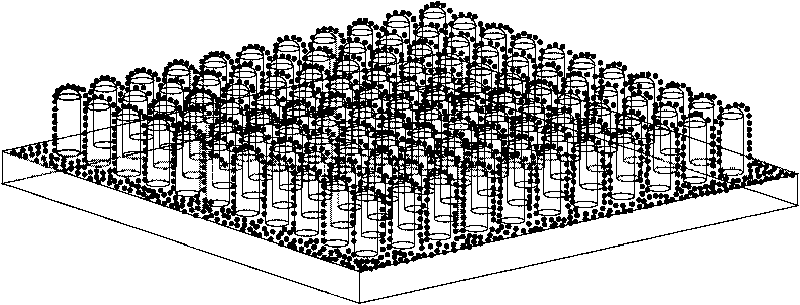

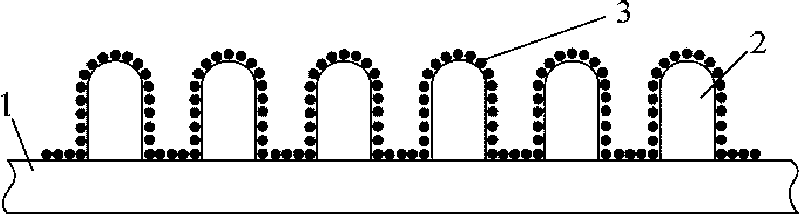

[0031] Such as figure 1 As shown, this embodiment includes: a substrate 1, a hydrophobic microstructure 2 and a hydrophobic nano-modified film 3, wherein: the hydrophobic microstructure 1 is connected to the upper surface of the substrate 1, and the secondary hydrophobic nano-film 3 is located on the upper surface of the hydrophobic microstructure 2, forming Functional surfaces with superhydrophobic properties.

[0032] The base 1 is an aircraft skin made of aluminum alloy;

[0033] The hydrophobic microstructure 2 is a vertical columnar array structure, including a number of metal columns 4 with a parallel spacing of 10 microns. The metal columns are cylinders, the lower end of which is fixedly connected to the substrate, and the cross section of the upper end is a square structure.

[0034] The contact area between the metal pillar 4 and the substrate 1 is 100 square micrometers, and the height is 3 micrometers.

[0035] The components and contents of the hydrophobic nano-...

Embodiment 2

[0044] Anti- / de-icing surface of aircraft based on micro-nano superhydrophobic structure using cones as hydrophobic microstructures

[0045] Figure 5 uses a cone with a needle-point shape on the upper end surface as the hydrophobic microstructure 2. As shown in the figure, the hydrophobic microstructure 2 of the super-hydrophobic aircraft anti- / de-icing surface based on the micro-nano scale structure is formed by the cone on the aircraft. Arrayed on the leather base 1, the height of the conical microstructure 2 is 3-15 microns, and the radius of the lower end section is 5-50 microns. The array distribution pitch and the coating form of the nano-modified film 3 are consistent with those in Example 1. The preparation method of this embodiment is basically the same as that of Example 1.

Embodiment 3

[0046] Embodiment 3 adopts cuboid as the aircraft anti-icing / de-icing surface based on the micro-nano superhydrophobic structure of the hydrophobic microstructure

[0047] Fig. 6 is the schematic diagram of the aircraft anti- / de-icing surface structure based on the micro-nano super-hydrophobic structure of the present embodiment where the hydrophobic micro-structure 2 is a cuboid. , arrayed on the aircraft skin substrate 1, the height of the cuboid microstructure 2 is 3-15 microns, the cross-section can be square or rectangular, the length of the cross-section is 5-50 microns, and the width is also 5-50 microns. The nanoparticle radius of the hydrophobic nano-modified film 3 on the superhydrophobic surface, the array distribution spacing of the cuboids on the aircraft skin substrate 1, and the coating form of the nano-modified film 3 are consistent with those in Example 1. The preparation method of this embodiment is basically the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com