Multifunctional combined atomizing lance

An atomization spray gun, multi-functional technology, applied in the field of multi-functional joint atomization spray gun, can solve the problems of inconvenient operation, burner outage, etc., and achieve the effects of good atomization effect, compact and simple structure, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

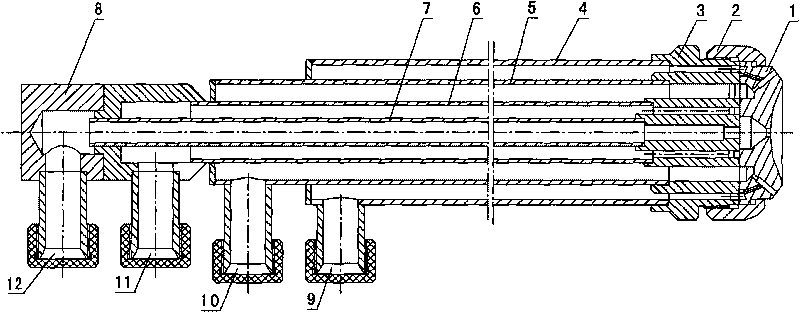

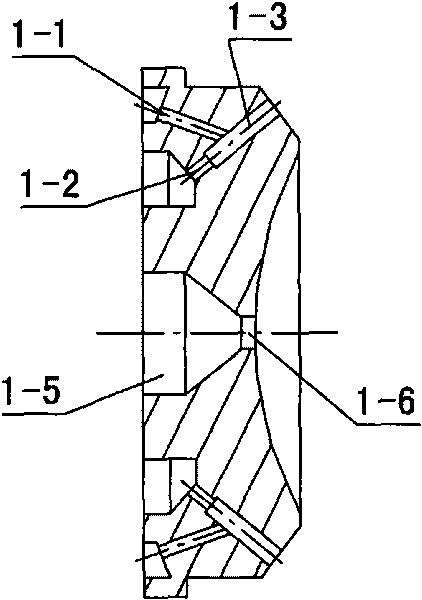

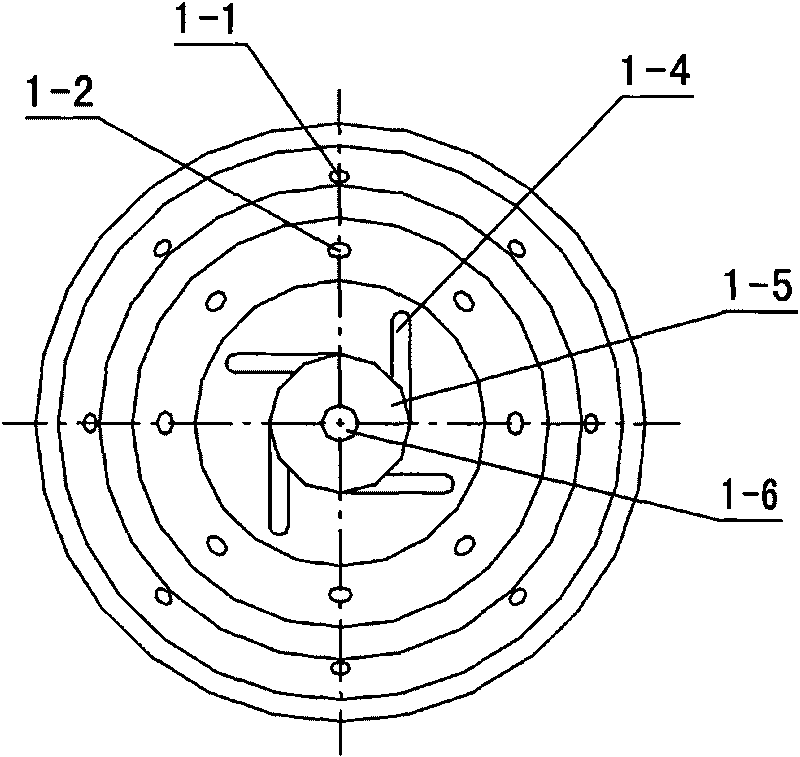

[0013] The multifunctional combined atomizing spray gun of the present invention is mainly composed of a combined atomizing nozzle, a compression nut 2, a multi-layer shunt 3, an outer gun barrel 4, a medium conduit 5, an inner gun barrel 6, a central gun barrel 7, and a combined gun seat 8 , Four sets of pipe joints. Wherein: the inner gun barrel 6, the medium conduit 5 and the outer gun barrel 4 are stacked on the outside of the central gun barrel 7 in a stepped order to form the gun body, and the combined gun seat 8 is located at the afterbody of the gun body, and the combined gun seat 8 is respectively fixed by The central gun barrel 7 and the inner gun barrel 6 are composed of two casing pipes, and the light fuel return pipe joint 12 communicated with the central gun barrel 7 and the light fuel inlet connected with the inner gun barrel 6 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com