Long service-life ceramic metal halide lamp and manufacturing method thereof

A technology of ceramic metal halide lamps and manufacturing methods, which is applied in the manufacture of discharge tubes/lamps, ships or lead-in wires, cold cathodes, etc., and can solve problems such as seal failure and halide rapid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

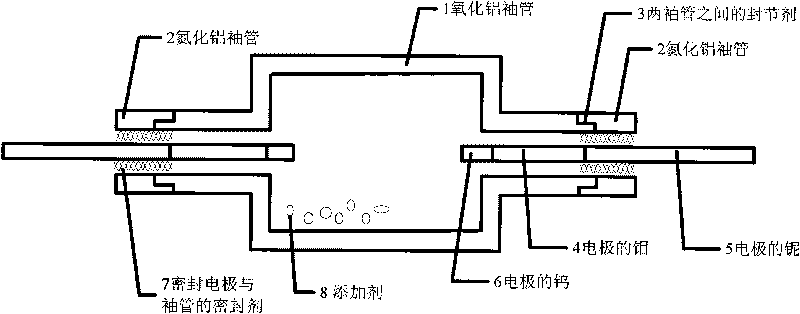

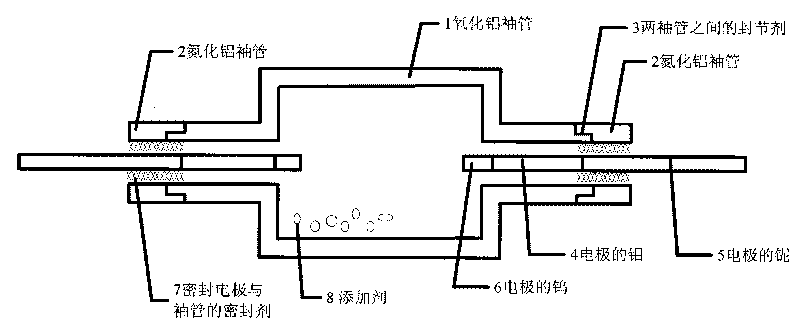

[0019] The structural diagram of the present invention is as figure 1 shown, including alumina (Al 2 o 3 ) sleeve tube 1, aluminum nitride (AlN) sleeve tube 2, sealant between the two sleeve tubes 3, molybdenum (Mo) 4 for the electrode, niobium (Nb) 5 for the electrode, tungsten 6 for the electrode, used to seal the electrode and the sleeve tube The sealant 7 and the appropriate amount of additives 8 composition.

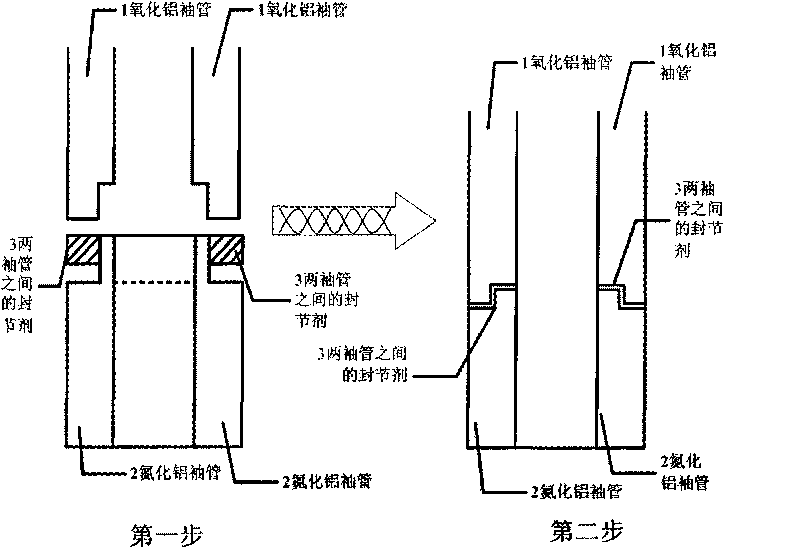

[0020] It can be seen that the design of aluminum nitride (AlN) sleeve 2 is one with aluminum oxide (Al 2 o 3 ) Sleeve 1 has a plug-type short tube with the same inner and outer diameters, and with aluminum oxide (Al 2 o 3 ) at the interface of the sleeve 1, the trapezoidal structure of the aluminum nitride (AlN) sleeve 2 and the aluminum oxide (Al 2 o 3 ) The trapezoidal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com