Device and method for detecting heat conducting property of high bulky easily-deformable material

A technology of thermal conductivity and detection device, which is applied in the field of detection device for thermal conductivity of warm-filling flake materials, which can solve the problem that the possible changes of thermal conductivity cannot be examined, the direction of heat transmission is not one-dimensional, and the measurement of sample thickness cannot be actively controlled. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

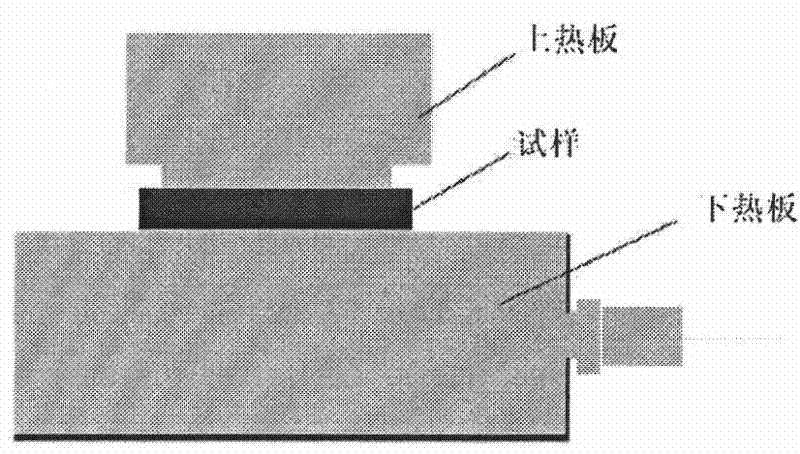

Method used

Image

Examples

Embodiment 1

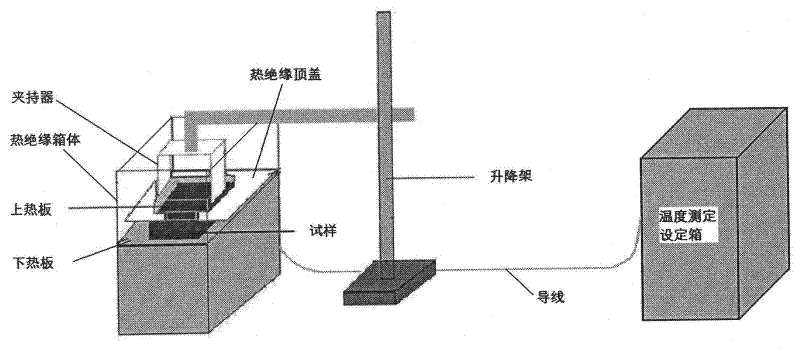

[0035] Embodiment 1: use the plexiglass that thickness is 4mm to make thermal insulation device, and each part size is as follows: heat insulation box side length a=188mm; Heat insulation box height b=150mm; Heat insulation top cover outer side length c=180mm; The thickness of the insulating top cover d=20mm; the inner side length of the heat insulating top cover e=50mm. The sample thickness active control device is made of medium carbon steel, in which the holder is made of 440-C stainless steel, the lifting arm is made of 154CM stainless steel, and the lifting frame is made of ATS-34 steel. The dimensions of each part are as follows: the height of the lifting frame f=300mm; the length of the gripper g=80mm; the height of the gripper h=60mm.

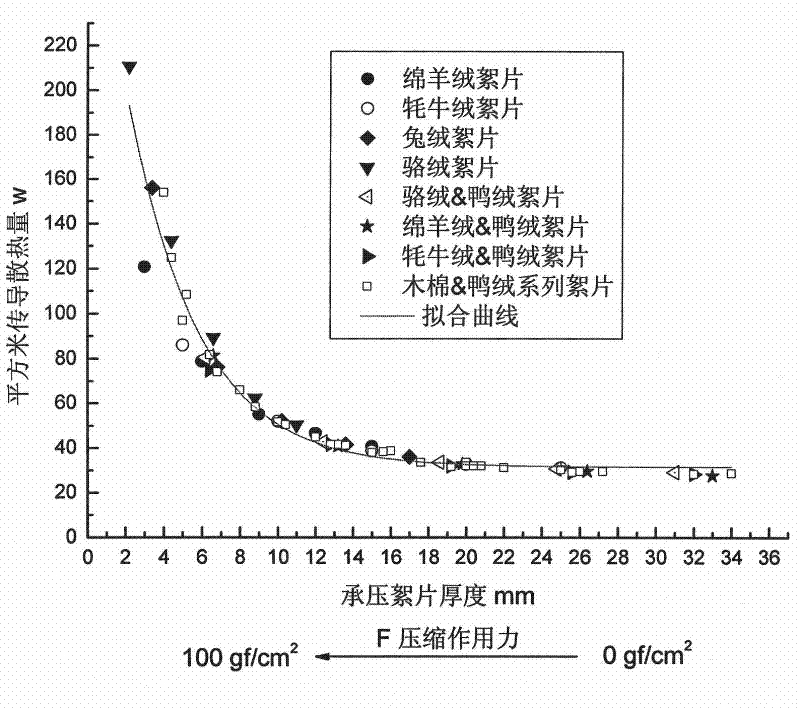

[0036] Install the detection device of the present invention on the KES-F7 test system made in Japan to test the conduction heat dissipation of 7 kinds of flakes under the initial thickness, and the corresponding conduction heat dissipa...

Embodiment 2

[0043] Embodiment 2: use a bakelite board with a thickness of 2mm to manufacture a thermal insulation device, and the dimensions of each part are as follows: the side length of the thermal insulation box a=184mm; the height of the thermal insulation box b=120mm; the outer length of the thermal insulation top cover c=180mm; The thickness of the insulating top cover d=15mm; the inner side length of the heat insulating top cover e=50mm. The lifting arm of the thickness active control device is made of aluminum alloy, the gripper is made of 440-C stainless steel, and the lifting frame is made of ATS-34 steel. The dimensions of each part are as follows: the height of the lifting frame f = 280mm; the length of the gripper g = 80mm; the height of the gripper h = 50mm.

[0044] The detection device was installed on the KES-F7 test system produced in Japan to test the properties of the seven flakes shown in Table 1. Each flake was tested under the same temperature and humidity conditi...

Embodiment 3

[0045] Embodiment 3: use vacuum glass with a thickness of 8mm to manufacture a thermal insulation device, and the dimensions of each part are as follows: the side length of the thermal insulation box a=196mm; the height of the thermal insulation box b=120mm; the outer side length of the thermal insulation top cover c=180mm; The thickness of the insulating top cover d = 30mm; the inner side length of the heat insulating top cover e = 50mm. The lifting arm of the thickness active control device is made of copper alloy, the gripper is made of 440-C stainless steel, and the lifting frame is made of ATS-34 steel. The dimensions of each part are as follows: the height of the lifting frame f = 350mm; the length of the gripper g = 80mm; the height of the gripper h = 80mm.

[0046] The detection device was installed on the KES-F7 test system produced in Japan to test the properties of the seven flakes shown in Table 1. Each floc is tested under the same temperature and humidity condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com