Microscale reactor for synthesizing radioactive drug and application thereof

A micro-reactor, radiopharmaceutical technology, applied in laboratory containers, preparation of organic compounds, introduction of isotopes into organic compounds, etc., can solve problems such as difficulty in reducing costs, large reaction volume, and many synthetic reagents, and reduce consumption. , The process method is simple and easy to implement, the effect of reducing space and capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

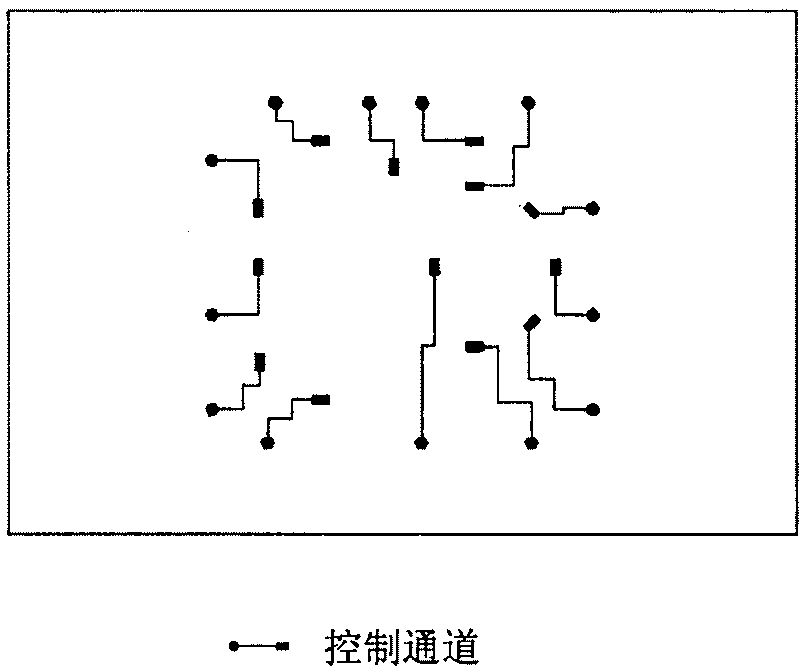

Image

Examples

Embodiment 1

[0052] Example 1: Labeled synthesis of 18F-deoxyglucose ( Figure 9 ):

[0053] Since in the microfluidic chip of the present invention, the power of liquid flow comes from pneumatic pressure, the amount of reagents added is quantitative, that is, the reagents to participate in the reaction are added to the corresponding pipelines in advance, and the addition of reagents is an "all or nothing" formula, That is, either all of them are added, or they are not added at all, and there is no intermediate form. The air pressure of the liquid is 20-40Kpa, and the air pressure of the gas control valve is 60-150Kpa.

[0054] When the equipment is in the ready state, the Q1, Q2-Q13 pipes are all pressurized at 60-90Kpa, and all valves are closed at this time. The adsorption column 50 is pre-rinsed with 100ul of 0.5M K2CO3 solution, and then washed with 500ul of water until neutral. The liquid pipeline distributes and loads the corresponding reagents, that is, Y1: 500ul, 18F-H2O; Y2: w...

Embodiment 2

[0063] Example 2: Synthesis of 18F-fluoroacetate (18FAC) ( Figure 12 )

[0064] The air pressure of the liquid is 20-40Kpa, and the air pressure of the gas control valve is 60-150Kpa. When the equipment is in the ready state, the Q1, Q2-Q13 pipes are all pressurized at 60-90Kpa, and all valves are closed at this time. The adsorption column 50 is pre-rinsed with 100ul of 0.5M K2CO3 solution, and then washed with 500ul of water until neutral. The liquid pipeline distributes and loads the corresponding reagents, that is, Y1: 500ul, 18F-H2O; Y2: waste liquid bottle; Y3: 20ul eluent (K222, 300mg / K2CO3, 55mg / 0.5mlH2O / 19.5mlMeCN); Y4: 20ul anhydrous Acetonitrile; Y5: 20ul O-ethylglycolate methanesulfonate EOMG (5ulEOMG / 500ul anhydrous acetonitrile); Y6: 100ul water; Y7: 40ul, 1N NaOH: Y8: 80ul, 0.5N HCl; Y10: 200ul of water; Y11: waste liquid bottle (empty); In addition, the outlet of the Y9 pipeline is connected to the adsorption hydrolysis column Oasis-HLB (diameter 2.5×15mm). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com